Description

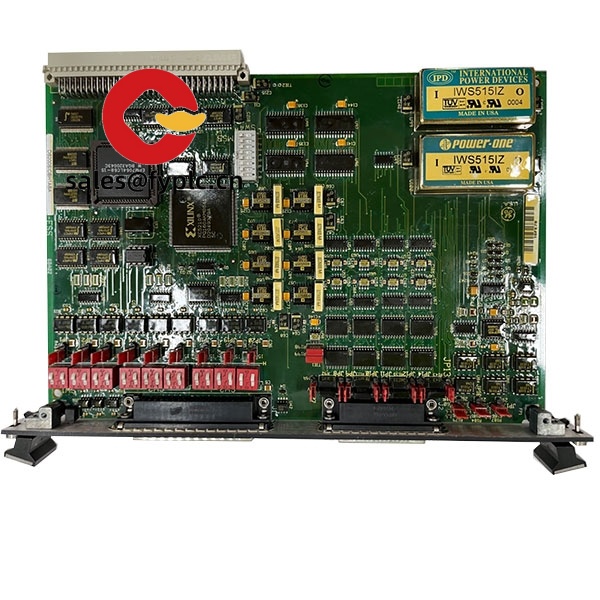

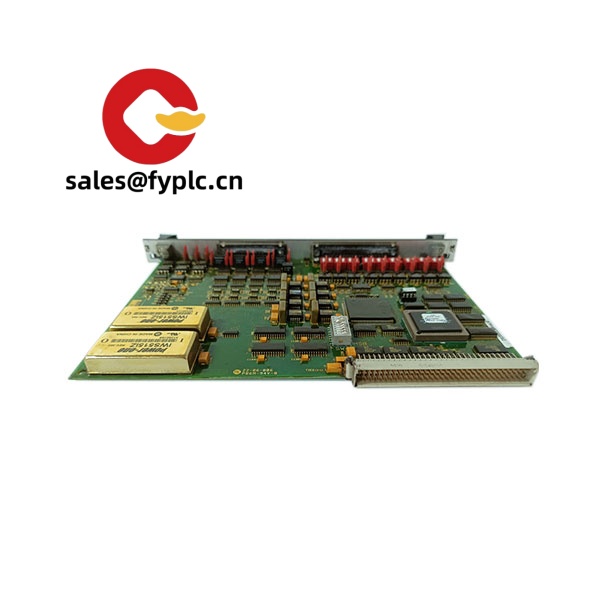

GE DS200SIOBH1ABA Serial I/O Board – Stable communications interface for GE Mark V/drive and exciter systems

The GE DS200SIOBH1ABA is a Serial I/O Board from the DS200 family used in GE Mark V turbine control, as well as many GE drive/excitation cabinets. From my experience, it’s typically selected when you need dependable, noise‑tolerant serial links between the controller and external devices like HMIs, PLCs, data loggers, or modems. You might notice that the ABA revision denotes an incremental update over earlier DS200SIOBH1 builds, which in many cases helps with long-term spares compatibility and drop‑in replacement behavior.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Multi‑channel serial communications – Supports multiple independent channels (commonly RS‑232 and RS‑422/485) for linking controllers to HMIs, PLCs, printers, and remote interfaces.

- Configurable via jumpers/DIP settings – Baud rate, mode, and termination are typically jumper‑selectable, making field configuration straightforward.

- Noise‑resistant design – Differential transceivers and board‑level grounding practices help maintain stable links in high‑EMI cabinets.

- Diagnostic indicators – Status LEDs (where fitted) give quick visual feedback during commissioning and troubleshooting.

- DS200 backplane compatible – Plug‑in replacement in GE Mark V and many GE drive/exciter racks; minimizes wiring changes.

- ABA revision continuity – The DS200SIOBH1ABA revision is typically firmware/feature compatible with prior H1 series, easing mixed‑fleet spares management.

Technical Specifications

| Brand / Model | GE DS200SIOBH1ABA |

| HS Code | 8538.90 (Parts suitable for use with industrial control equipment) |

| Power Requirements | 5 VDC logic power from DS200/Mark V backplane (typ. <10 W) |

| Dimensions & Weight | Standard DS200 full‑size PCB; approx. 280 × 215 mm; ~0.7 kg (typical) |

| Operating Temperature | 0 to +60 °C (when installed in a ventilated control cabinet) |

| Signal I/O Types | Serial I/O channels; RS‑232 and RS‑422/485 options (model/cabinet dependent) |

| Communication Interfaces | Multiple UART‑based ports; typical field settings 1.2–19.2 kbps; configuration via on‑board jumpers/DIP switches; connection via headers or cabinet terminal boards |

| Installation Method | Plug‑in PCB on standoffs into DS200/Mark V rack; mates to backplane connectors; secure with hardware and follow ESD procedures |

Application Fields

Typical use cases include:

- GE Speedtronic Mark V gas/steam turbine control cabinets for serial links to HMIs and plant DCS nodes

- GE drive systems (e.g., DC2000/AC2000) and EX2000 exciters, providing external device connectivity

- Industrial plants in power generation, metals, pulp & paper, and petrochemical environments that require stable serial communications in high‑EMI areas

One thing I appreciate is how predictable the board behaves during cabinet retrofits. A maintenance supervisor at a combined‑cycle site told us the ABA revision swapped straight in, and the RS‑422 link to their recorder stabilized without any software changes.

Advantages & Value

- Reliability in noisy cabinets – Designed for the electrical environment inside turbine and drive panels, which in many cases reduces intermittent comms faults.

- Compatibility – Works within the DS200 ecosystem; jumper options help match legacy settings without rewiring.

- Downtime reduction – Drop‑in replacement keeps turnaround tight; helpful when outages are measured in hours, not days.

- Procurement flexibility – Supports phased upgrades; you don’t have to change your HMI or DCS to stabilize the link.

- Technical support – We can share typical jumper maps and recommended cable practices for faster commissioning.

Installation & Maintenance

- Cabinet requirements – Mount in a clean, dry, ventilated enclosure; follow standard GE rack positions. Maintain airflow around heat‑generating components.

- Wiring practices – Use shielded twisted pair for RS‑422/485; terminate as required; keep serial runs away from high‑voltage cables. Ground shields at one end unless the site standard states otherwise.

- Configuration – Document existing jumpers/DIP positions before replacement. Typical baud rates are 1.2–19.2 kbps; match parity and stop bits across devices.

- Safety & ESD – Power down, lock‑out/tag‑out, and wear an ESD wrist strap. Avoid flexing the PCB when inserting/removing.

- Routine maintenance – Quarterly visual check of connectors and standoffs; clean dust with dry air; verify communication error logs. If firmware/parameter PROMs are fitted in your cabinet version, keep a labeled backup.

Quality & Certifications

- Manufactured within GE’s industrial controls quality system (suppliers are typically ISO 9001 certified)

- Installed systems commonly meet CE/UL when integrated in the approved cabinet; the spare board itself is typically not individually CE‑marked

- RoHS status may vary by production year; many legacy DS200 boards pre‑date full RoHS adoption

- Warranty: 365 days replacement/repair coverage

Related/Supporting Components

The DS200SIOBH1ABA is commonly deployed with other DS200 series modules and cabinet terminal boards. Typical companions include:

- DS200SDCCGxA control board (drive/exciter control core)

- DS200‑series terminal boards and ribbon/serial harnesses used to bring RS‑232/RS‑422/485 to field connectors

If you’re matching a specific cabinet, share the existing SIOB jumper map and the external device interface type (RS‑232 vs RS‑422/485). It appears that most issues we see after swap‑outs come down to a single mismatched jumper or termination setting.

Reviews

There are no reviews yet.