Description

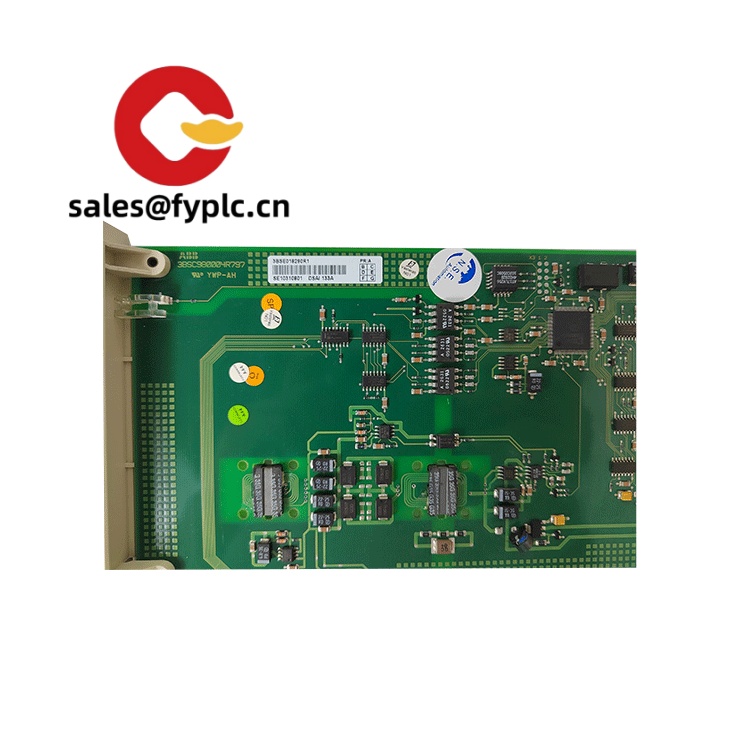

ABB DSAV110 57350001-E – Advant I/O Module for reliable process signal integration

The ABB DSAV110 (part no. 57350001-E) is a field-proven module from the Advant family that’s typically used to expand or interface process signals within existing ABB Advant/Advant Master systems. From my experience, sites choose this unit when they need a straightforward, rack-mounted module that drops into S-series I/O racks and keeps legacy assets running without a disruptive redesign. It seems to be especially handy in brownfield upgrades where continuity and spare parts strategy matter just as much as functionality.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In stock items typically ship within 1 week; not more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express couriers: FedEx, UPS, DHL

Key Features

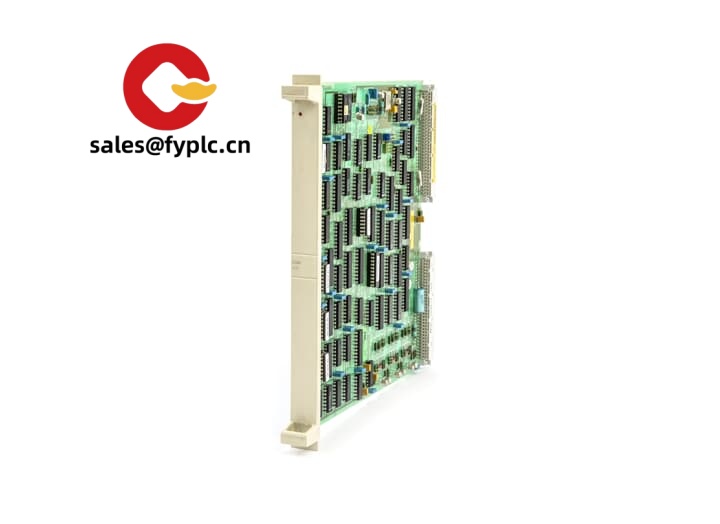

- Advant rack integration – Designed for ABB Advant installations; fits standard rack slots for fast swap and minimal wiring changes.

- Backplane-powered – Draws power via the system backplane, so no separate PSU wiring in most cases.

- Status indication – Front-panel LEDs (typical for this series) help with quick health checks during commissioning and troubleshooting.

- Industrial-grade build – Built for continuous operation in cabinet environments common to process industries.

- Lifecycle-friendly – A practical option for maintaining installed Advant assets, reducing the need for immediate platform migration.

Technical Specifications

| Brand / Model | ABB DSAV110 (Part No. 57350001-E) |

| System Compatibility | Advant / Advant Master rack-based I/O environments (S-series), subject to site configuration |

| HS Code (indicative) | 8538.90 – Parts suitable for apparatus of heading 8537 |

| Power Requirements | Supplied via backplane from the system power unit (no external feed in typical installations) |

| Communication/Bus | Rack backplane interface for Advant I/O subsystems |

| Signal I/O Types | Defined by the DSAV110 functional role in the Advant I/O set; confirm channel specifics against your installed base documentation |

| Installation Method | Plug-in module for Advant rack; cabinet-mounted in accordance with industrial control panel practices |

Application Fields

You’ll typically see the DSAV110 in process plants running ABB Advant—power generation, pulp & paper, oil and gas, chemicals, metals, and marine. One thing I appreciate is how easily it supports incremental expansions, like adding a few new measurement points on a mill line or integrating skid equipment without replacing the whole controller.

- Life extension projects for legacy Advant Master systems

- Targeted I/O additions during phased upgrades

- Critical spare holding to reduce downtime risk

- Like-for-like replacement to stabilize production after a module fault

“Swapped a DSAV110 during a weekend outage—no rewiring, just reseat, verify LEDs, and trend checks. Back on spec within the hour.” — Maintenance Lead, combined-cycle plant

Advantages & Value

- Reliability in service – Built for continuous duty; units are commonly used as long-term spares in heavy industry.

- Compatibility – Works within the Advant ecosystem, which in many cases means zero PLC code changes for like-for-like replacement.

- Cost control – Extends system life and defers large-scale migrations; typically the quickest way to recover I/O functionality.

- Technical support – We assist with part verification (rev/series), slotting guidance, and pre-shipment functional checks.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated control cabinet; maintain typical panel temperatures for Advant hardware.

- Mounting – Power down the rack, seat the module firmly into the designated slot, and secure per ABB rack instructions.

- Wiring – Use the existing terminal base/connector set associated with the slot; verify pinout matches the module function.

- ESD care – Handle with grounding strap; avoid touching connector fingers and components.

- Commissioning – After insertion, check front LEDs, confirm bus recognition at the controller, and validate I/O points in the HMI.

- Routine maintenance – Keep cabinet filters clean, periodically retighten field wiring, and document firmware/revision levels if applicable.

- Spares strategy – In most cases, holding at least one tested spare per critical rack is a practical buffer against unexpected trips.

Quality & Certifications

- Quality standards – ABB manufacturing typically aligns with ISO-based quality systems.

- Regulatory – CE marking is common for this product family; UL/CSA recognition may apply depending on the specific unit and market.

- Material compliance – RoHS status can vary by production vintage for legacy Advant modules; confirm if a project requires strict RoHS.

- Warranty – 365-day warranty coverage.

Supporting Components (often used together)

- DSMB series power supply modules – backplane power for the rack

- DSAI / DSAO / DSDI / DSDO series – analog and digital I/O modules for Advant

- DSBC controller modules – Advant controller CPUs supervising the I/O rack

- Terminal bases and field connectors – as required by the specific slot and wiring scheme

If you share your rack type, slot plan, and current firmware/revision details, we can verify DSAV110 57350001-E fitment and confirm any revision-matching considerations before shipment.

Reviews

There are no reviews yet.