Description

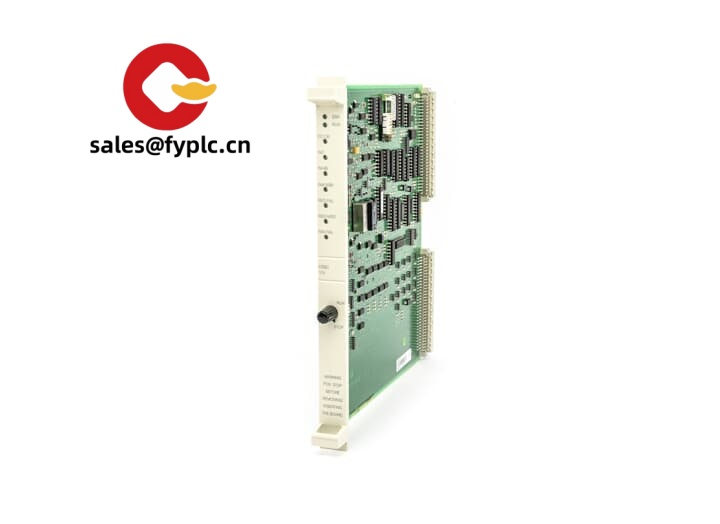

ABB DSBC174 (3BSE012211R1) – System Communication/Backplane Board for 800xA and Advant Controllers

The ABB DSBC174, part number 3BSE012211R1, is a plug‑in system board used in ABB controller racks to manage internal bus communication and module interfacing. From my experience, it’s typically deployed in 800xA/Advant-based cabinets as a reliable backplane interface that keeps controller modules synchronized and the system bus stable. You might notice that it isn’t a field I/O module—there are no front terminals—because it handles the internal signaling that lets the CPU and I/O/communication modules talk cleanly across the rack. As a spare, it seems to be one of those parts that prevents intermittent bus faults and nuisance resets when replaced proactively.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week when in stock; no more than 1 month at the latest

- Payment: 50% advance; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Backplane bus handling – Ensures stable internal communication between controller CPU and I/O/communication modules.

- Rack plug‑in form factor – Slides into the designated ABB rack slot; no field wiring on the front, which simplifies swaps.

- Designed for ABB 800xA/Advant environments – Commonly used in ABB DCS/PLC cabinets; supports mainstream controller architectures.

- Service-friendly replacement – In many cases, a direct, drop‑in replacement minimizes downtime during maintenance windows.

- Industrial temperature range – Built for cabinet operation in typical plant conditions.

- Long-term availability as a spare – Useful for life‑cycle support of installed ABB control systems.

Technical Specifications

| Brand / Model | ABB DSBC174 (3BSE012211R1) |

| HS Code | 853890 (Parts for electrical control equipment; subject to local classification) |

| Power Requirements | Supplied via system backplane; 5 VDC rail typical (no external power terminals) |

| Dimensions & Weight | Rack plug‑in board; typically < 0.5 kg; standard ABB slot footprint |

| Operating Temperature | Typically 0 to +55°C (cabinet installation) |

| Signal I/O Types | Internal system bus signals; no direct field I/O terminals |

| Communication Interfaces | Backplane/system bus interface; front panel typically without user ports |

| Installation Method | Plug‑in to ABB controller rack; retained with captive screws; hot‑swap depends on system design and maintenance policy |

Application Fields

The DSBC174 is typically used in DCS/PLC cabinets across power generation, oil & gas, chemicals, pulp & paper, mining & metals, and water treatment. It fits well where ABB 800xA or Advant-based controllers manage continuous processes and need stable internal communication within the rack. One maintenance lead at a paper mill told me they swapped this board during a scheduled stop and cleared an intermittent bus fault in under 20 minutes—no retesting of field circuits was required since it doesn’t wire to the field.

Advantages & Value

- Reliability – Stabilizes the controller’s internal bus, which, in many cases, reduces unexplained module dropouts.

- Compatibility – Purpose-built for ABB racks, so it’s a straight fit with standard mechanicals and backplane connectors.

- Lower downtime risk – Swap is quick; no field wiring means shorter maintenance windows and less validation effort.

- Total cost control – Keeps legacy cabinets productive without full system upgrades; ideal for phased modernization plans.

- Technical support – We assist with revision matching and on-site spares strategy to avoid firmware and compatibility surprises.

Installation & Maintenance

- Install in a clean, ventilated control cabinet (IEC/EN compliant). Maintain ambient typically within 0–55°C and avoid condensation.

- De‑energize the rack as per site procedures, unless your system supports hot swap and you’ve planned the risk assessment accordingly.

- Seat the board firmly into the backplane; tighten captive screws to manufacturer torque guidelines to prevent vibration‑related intermittents.

- Cable management: keep power and high‑noise conductors separated from controller bays to limit EMI.

- Routine maintenance: periodic cabinet dust removal, connector inspection, and checking event logs for bus errors. Firmware alignment should follow your DCS configuration control policy.

- Keep at least one tested spare on site; from my experience, that’s what shortens unplanned downtime the most.

Quality & Certifications

- Manufactured by ABB under ISO 9001 quality systems

- CE compliant for industrial environments

- UL/CSA recognition for industrial control equipment (region dependent)

- RoHS compliant on current revisions

- Warranty: 12 months (365 days)

If you need help confirming rack compatibility or aligning hardware/firmware revisions for DSBC174 3BSE012211R1, share your controller type and existing part markings. One thing I appreciate is how predictable these swaps usually are once the revision check is done.

Reviews

There are no reviews yet.