Description

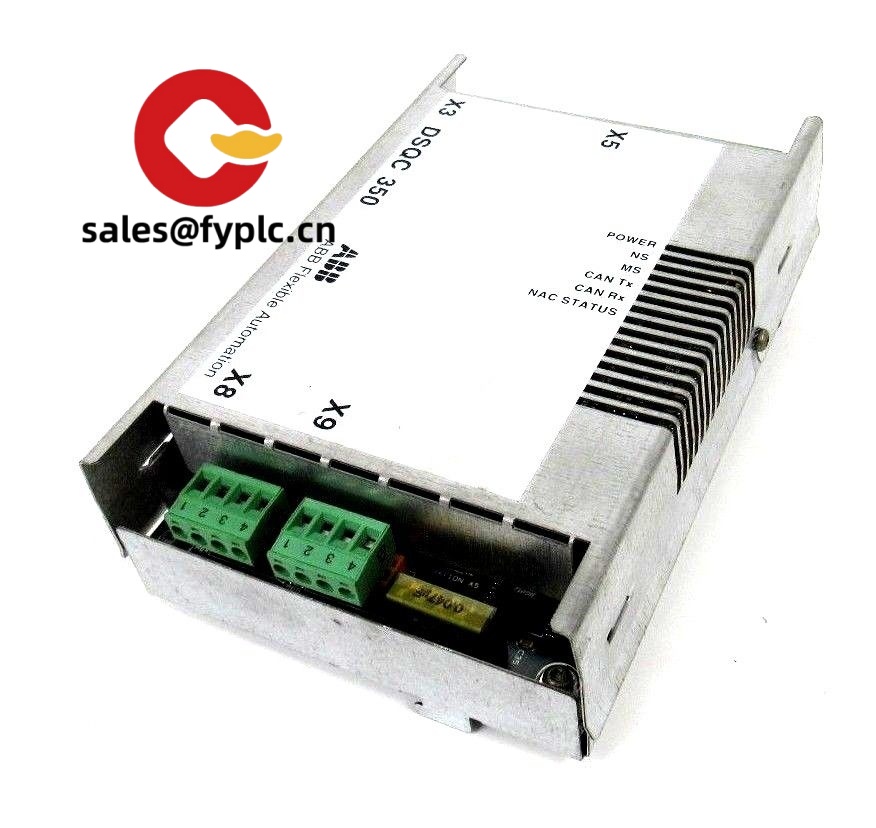

ABB DSQC350 (3HNE00025) – Controller Board for S4C/S4C+ Robot Systems

The ABB DSQC350, part number 3HNE00025, is a controller board used in ABB S4C/S4C+ robot controllers. From my experience, this board is commonly selected as a direct, drop‑in replacement to stabilize axis control and restore reliable motion after intermittent faults or communication errors inside the control cabinet. You might notice that it prioritizes robust backplane connectivity, quick diagnostics, and long-term reliability—exactly what a maintenance team needs when downtime is costly.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: Typically 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Packing: ESD-safe, foam protected; each board is visually inspected before dispatch

Key Features

- Native compatibility with ABB S4C/S4C+: Designed to integrate into the original ABB rack, keeping your existing wiring and system layout intact.

- Backplane-powered design: Draws power from the controller’s internal 24 VDC backplane, simplifying installation and reducing wiring risk.

- Diagnostic indicators: On-board status LEDs (typical on DSQC boards) help technicians confirm power, bus status, and basic health at a glance.

- Proven field reliability: DSQC-series boards are well regarded for stable operation in round-the-clock production cells.

- Traceable ABB part number: Marked as 3HNE00025, assisting with change control and maintenance documentation.

- Drop‑in replacement workflow: Usually no mechanical modification; in many cases it’s plug, secure, and run system verification.

Technical Specifications

| Brand / Model | ABB DSQC350 (3HNE00025) |

| Product Type | Controller board for ABB S4C/S4C+ robot controllers |

| HS Code | 853890 (Parts for electrical control/distribution equipment) |

| Power Requirements | Supplied via controller backplane (24 VDC internal); low power draw, typically < 10 W |

| Operating Temperature | 0–45 °C inside a ventilated control cabinet (typical) |

| Signal I/O Types | Internal axis/drive control and system bus signals via ABB proprietary interfaces (backplane) |

| Communication Interfaces | S4C/S4C+ backplane connector; internal system bus |

| Installation Method | Rack-mounted PCB; single-slot board secured with retainers/screws in the controller rack |

| Compatible Systems | ABB S4C / S4C+ controller families used with IRB robots (e.g., IRB 140, IRB 2400, IRB 4400, depending on configuration) |

Application Fields

This board is typically deployed anywhere S4C/S4C+ robots are still running in production:

- Automotive body-in-white cells, spot welding gantries, and material handling lines

- Machine tending for CNCs in metal fabrication and precision assembly

- Plastics and packaging cells requiring consistent indexing and pick-and-place

- Palletizing and kitting stations where uptime and repeatability matter

- General manufacturing retrofits extending the service life of legacy ABB robots

A maintenance lead recently summed it up well: “Swapped the DSQC350 on a Friday night, rechecked the system data, and the axis following errors were gone. We were back in production before shift change.” Your mileage may vary, but that’s a common outcome when the original board is failing intermittently.

Advantages & Value

- Minimized downtime: Direct replacement keeps installation fast; most teams can validate within one maintenance window.

- Compatibility first: Works with existing S4C/S4C+ racks and cabling, avoiding broader system changes.

- Cost control: Extends the utility of legacy ABB cells without the budget hit of a full controller upgrade.

- Technical support: Guidance on board swap, firmware matching, and system backup/restore helps reduce commissioning time.

Installation & Maintenance

- Environment: Install in a clean, ventilated control cabinet. Keep airflow unobstructed and avoid conductive dust.

- ESD safety: Use wrist straps and ESD mats. Power the controller down fully before handling the board.

- Mounting: Seat the DSQC350 evenly into the backplane; tighten captive screws/retainers to the manufacturer’s recommended torque.

- Wiring & checks: After installation, verify all connectors are fully home, run system self-tests, and clear any diagnostics.

- Firmware/config: Ensure RobotWare version and system configuration match your cell. Back up the system before the swap; restore if needed.

- Routine care: Quarterly cabinet cleaning (dry air, low pressure), visual inspection for heat discoloration, and log review for emerging faults.

Quality & Certifications

- Certifications (board/controller context): CE marked; RoHS compliant in most cases; UL/cUL typically applies at the controller assembly level.

- Traceability: Labeled with ABB part number 3HNE00025 for maintenance documentation.

- Warranty: 365 days, covering manufacturing defects and normal-use failures.

Related/Supporting Components

For planned downtime, many teams also stage critical spares around the same rack position:

- ABB DSQC-series backplane boards used in S4C/S4C+ racks

- Teach pendant and system I/O boards appropriate to your RobotWare version

- Fan assemblies and power supply modules for the S4C/S4C+ cabinet

If you share your controller type and RobotWare level, we can typically confirm slot mapping and compatibility before you schedule the swap.

Reviews

There are no reviews yet.