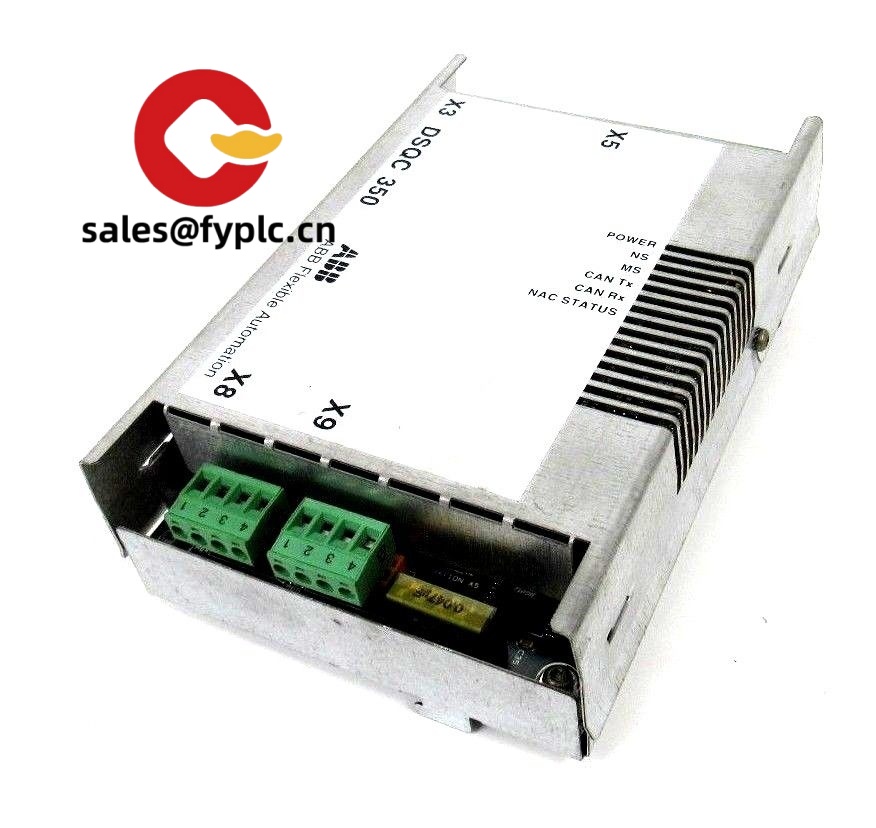

Description

ABB DSQC377B – I/O Interface Board for S4C/S4C+ Robot Controllers

The ABB DSQC377B is a controller-mounted I/O interface board used in many S4C/S4C+ robot cabinets to handle 24 VDC field signals and connect peripheral devices to the robot system. From my experience, it’s the go-to replacement when a robot cell starts throwing intermittent I/O faults or when you’re expanding a line and need reliable, deterministic I/O handling without redesigning the whole cabinet. You might notice that integration is straightforward—ribbon harnesses and terminal boards usually remain unchanged, making it a clean drop-in when time is tight.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Each unit is function-checked prior to dispatch. Packaging is ESD-safe and transport-rated to reduce in-transit risk.

Key Features

- Native fit for S4C/S4C+ – Designed to mount inside ABB S4C/S4C+ controller racks, keeping wiring layouts and harness lengths intact.

- 24 VDC digital signal handling – Typically used for standard industrial sensors, pushbuttons, and solenoid-triggered outputs.

- Backplane communication – Uses the ABB controller backplane for low-latency I/O updates and robust synchronization with the main CPU.

- Practical diagnostics – Status indications (onboard LEDs in many cases) help maintenance teams verify signal state and board health at a glance.

- Drop-in replacement – Minimizes downtime; most field terminal blocks and ribbon connectors remain unchanged during swap.

- Stable in harsh environments – Built for cabinet-mounted operation in typical plant conditions (automotive, packaging, metals).

Technical Specifications

| Brand / Model | ABB DSQC377B |

| HS Code | 8538.90 (Parts suitable for use with 8535/8536/8537 apparatus) |

| Power Requirements | Supplied from controller backplane, 24 VDC; typical board consumption < 10 W |

| Dimensions & Weight | Controller PCB form factor for S4C/S4C+ rack; typical net weight approx. 0.3–0.5 kg |

| Operating Temperature | 0 to +45 °C (cabinet environment) |

| Signal Input/Output Types | 24 VDC digital inputs/outputs via internal harness to terminal boards; channel count depends on controller configuration |

| Communication Interfaces | ABB controller backplane interface; field wiring via ribbon/terminal connections inside the cabinet |

| Installation Method | Rack-mounted board inside the robot controller (S4C/S4C+), seated into designated slot |

Application Fields

Typical use cases include digital I/O expansion and signal interfacing in ABB robot cells across:

- Automotive body shops (spot welding fixtures, clamps, part-present sensing)

- Packaging and palletizing lines (conveyors, diverters, light curtains—non-safety circuits)

- Metalworking and machining cells (part detection, feeder interlocks)

- General assembly stations where deterministic robot-driven I/O is required

One thing I appreciate is how it keeps legacy S4C/S4C+ assets productive—teams can add or replace I/O capacity without redesigning the cabinet, which in many cases saves several maintenance shifts.

Advantages & Value

- Reliability – Stable backplane communication and robust industrial PCB design help reduce nuisance trips.

- Compatibility – Works within the ABB S4C/S4C+ ecosystem; no custom firmware loading in typical replacements.

- Cost control – Extends the life of existing controllers; avoids premature migration to newer control cabinets.

- Technical support – We can assist with slot mapping, I/O verification, and power budgeting to speed up commissioning.

A maintenance lead from a tier‑1 auto supplier summed it up well: “Swapping the DSQC377B cleared our random input glitches—no rewiring, just reseat, address, and we were back in production before the second break.”

Installation & Maintenance

- Cabinet standards – Install in a clean, dry, ventilated controller cabinet (S4C/S4C+). Maintain ambient 0–45 °C and avoid vibration.

- ESD handling – Use ESD grounding straps and antistatic packaging when handling or storing the board.

- Wiring – Power down the controller. Label and verify ribbon cables/terminal harnesses before removal. Check seating and backplane alignment.

- Verification – After installation, run I/O tests in the robot HMI and confirm channel state changes at the field terminals.

- Routine care – Quarterly dust-out with dry air (regulated), inspect connectors for oxidation, and reseat if needed. No calibration is typically required.

- Firmware compatibility – Board behavior follows the controller’s RobotWare level; keep the controller’s software maintained and backed up.

- Safety note – Use approved safety relays/PLC for safety circuits; this board is not a dedicated safety controller.

Quality & Certifications

- Designed for use in CE-marked ABB robot systems; UL compliance applies at the cabinet/system level.

- RoHS/WEEE adherence typically follows the manufacturing vintage and regional requirements.

- 365-day warranty coverage on supplied units.

Related Accessories (on request)

- I/O terminal boards and ribbon harnesses compatible with S4C/S4C+ racks

- 24 VDC sensor power distribution modules and fused output blocks

- ESD-safe handling kits and cabinet filter sets for routine upkeep

Reviews

There are no reviews yet.