Description

GE PACSystems RX3i IC695CPE310-ACAT – Compact CPU for reliable mid-range machine and process control

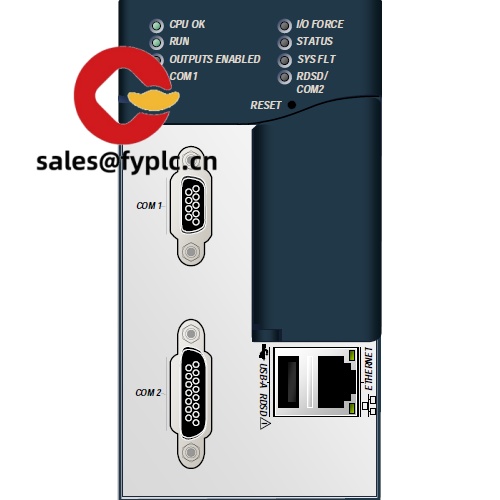

The IC695CPE310-ACAT is a PACSystems RX3i controller CPU designed for applications that need dependable logic execution, Ethernet connectivity, and straightforward lifecycle maintenance—without the cost or complexity of top-end processors. From my experience, it’s a solid fit for packing machines, utilities skids, and small cell-based lines where scan-time stability and easy networking matter more than bleeding-edge speed. The -ACAT suffix indicates a specific hardware/firmware revision of the CPE310; functionally it behaves like the base CPE310 CPU, with revision-level improvements that, in many cases, enhance lifecycle compatibility and serviceability.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- RX3i single-slot CPU – Installs directly in IC695 backplanes, leaving plenty of rack space for I/O and comms.

- Integrated Ethernet for programming and HMI/SCADA – Typically supports SRTP and Modbus/TCP communications for quick integration with SCADA and HMIs.

- Deterministic logic execution – Suits mid-range applications where consistent scan times and stable task handling are key.

- Flexible I/O architecture – Works with local RX3i I/O on the same backplane; distributed I/O is achievable via PROFINET (with a separate PNC module) or Ethernet devices.

- Lifecycle-friendly firmware and tools – Programmed via Proficy Machine Edition; firmware updates and backups are typically straightforward over Ethernet.

- Industrial environment ready – Standard RX3i environmental ratings for control cabinets; the -ACAT revision helps align with current manufacturing standards.

“We swapped a legacy CPU for the CPE310 and kept the original I/O—commissioning was quicker than expected, and the Ethernet link to SCADA came up right away.” — Maintenance Supervisor, food packaging line

Technical Specifications

| Brand / Model | GE PACSystems RX3i / IC695CPE310-ACAT |

| HS Code | 8537.10 (Programmable controllers, for a voltage ≤ 1000 V) |

| Power Requirements | Supplied by RX3i backplane (3.3 VDC via rack power supply); typical low power CPU consumption |

| Dimensions & Weight | Single-slot RX3i module; standard RX3i form factor |

| Operating Temperature | 0°C to 60°C (typical for RX3i modules) |

| Signal I/O Types | Controller CPU (no direct field I/O on the module); manages local RX3i I/O and networked devices |

| Communication Interfaces | Embedded Ethernet (10/100 Mbps, RJ‑45) for programming, HMI/SCADA; supports SRTP and Modbus/TCP in most cases |

| Installation Method | Mounts in IC695 RX3i rack (e.g., IC695CHS0x). Occupies one slot; secured with the module’s retaining screws. |

| Programming Software | Proficy Machine Edition (Logic Developer – PLC) |

Related or Supporting Products

- IC695CPE330 – Higher performance RX3i CPU with enhanced Ethernet capabilities; a good step-up when heavier logic, data handling, or networking is needed.

- IC695PNC001 – RX3i PROFINET Controller module for distributed I/O over PROFINET; pair with the CPE310 for scalable remote I/O.

- IC695ETM001 – Ethernet communications module; used when segmented networks or additional Ethernet ports are preferred.

- IC695PSD140 / IC695PSA040 – RX3i power supplies for the backplane.

- IC695CHS007 / IC695CHS012 – 7-slot and 12-slot RX3i racks (backplanes), respectively.

- IC693ACC302 – Backup battery pack for CPU memory retention (commonly used in RX3i/90-30 platforms).

Installation & Maintenance

- Cabinet & environment – Install in a grounded, ventilated control cabinet. Maintain ambient 0–60°C, 5–95% RH non-condensing. Keep clear airflow above/below the rack.

- Wiring – Use industrial-grade Ethernet cabling (Cat5e or better). Segregate communications and power wiring to limit noise. Bond cabinet ground to plant earth.

- Slotting – Seat the CPE310 fully into the IC695 backplane and tighten the retaining screws. From my experience, leaving 1 free slot between high-heat modules helps thermal stability in smaller enclosures.

- Firmware & backups – Maintain consistent firmware versions across spares. Keep project archives and CPU backups in Proficy Machine Edition. Plan firmware updates during scheduled downtime.

- Routine checks – Quarterly: inspect connectors, verify Ethernet link quality, review CPU scan times and diagnostics, and clean dust with dry air (low pressure).

- EMC practices – You might notice better network stability by using shielded Ethernet and proper cable management in VFD-heavy panels.

Quality & Certifications

- CE and UL/cUL compliance for industrial control equipment (typical for PACSystems RX3i)

- RoHS compliant design in most regions

- Manufacturer-grade quality control; firmware and hardware revisions tracked (this unit is the -ACAT revision)

- Warranty: 365 days

Note: Exact capabilities can vary slightly by firmware/hardware revision. If you’re replacing an older RX3i CPU or matching a validated system, share the existing hardware and firmware revisions—compatibility checks typically save time on site.

Reviews

There are no reviews yet.