Description

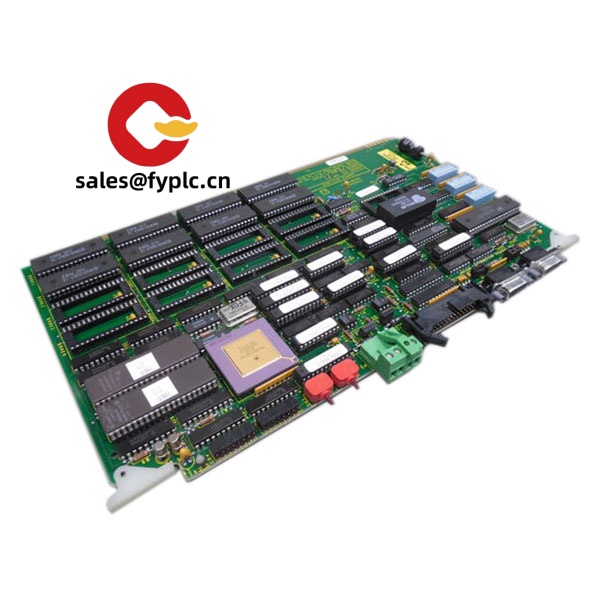

ABB IIMCP01 Communication Processor – Serial/Modbus integration for INFI 90 / Harmony systems

The ABB IIMCP01 is a dedicated communication processor module designed to bring serial field devices—like drives, analyzers, RTUs, and weigh scales—into ABB Bailey INFI 90 / Harmony control environments. From my experience, it’s the card many plants use when they need reliable Modbus RTU (master or slave) connectivity without adding an external gateway or rewriting controller logic. You might notice that it “just fits” the established Harmony/INFI 90 rack footprint, draws power from the backplane, and communicates on the system bus like any native I/O card.

Order Placement Process and Guarantees

- Warranty: 365 days (parts and workmanship)

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Native INFI 90 / Harmony integration – Plugs into the standard rack, communicates over the backplane, and is addressed like a regular control module.

- Serial protocol support – Typically used for Modbus RTU (master/slave) and asynchronous serial links for third‑party devices.

- Flexible port configuration – RS‑232 or RS‑485 selection for common instrument wiring; works well with multi‑drop RS‑485 networks.

- Deterministic data exchange – Scheduled polling reduces gaps and jitter in critical signals, which seems to be what maintenance teams appreciate in legacy plants.

- Backplane powered – No external power brick; less cabinet clutter and fewer points of failure.

- Service‑friendly – Status LEDs and clear diagnostics make it easier to validate comms, especially during turnaround windows.

Technical Specifications

| Brand / Model | ABB IIMCP01 |

| HS Code | 8538.90 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | Backplane supplied; 5 VDC (typical) from INFI 90 / Harmony rack power system |

| Operating Temperature | 0 to 60 °C (32 to 140 °F), non‑condensing environment |

| Signal I/O Types | Asynchronous serial; configurable RS‑232 / RS‑485 (typical), Modbus RTU master/slave support |

| Communication Interfaces | INFI 90 / Harmony backplane bus; front serial ports for field connectivity |

| Installation Method | Plug‑in module for standard INFI 90 / Harmony rack (single‑wide card) |

| Dimensions & Weight | Single‑wide INFI 90 form factor; typically under 1 kg |

Where it’s typically used

- Integrating VFDs and soft starters over Modbus RTU for speed, current, and alarm data

- Pulling measured values from gas analyzers or weigh scales into the control strategy

- Linking remote RTUs on multi‑drop RS‑485 lines back into the central INFI 90 / Harmony controller

One thing I appreciate is how stable the comms are once the line biasing and termination are set. In many cases, plants run long trunk lines on RS‑485 and still keep clean diagnostics and predictable polling cycles.

Related or Supporting Products

- ABB IIMCP02 – Similar role with updated hardware; typically supports higher serial throughput and larger data maps.

- ABB IMMFP01 / IMMFP02 – Multi‑Function Processors that execute the control strategy; IIMCP01 feeds them serial process data.

- ABB INNIS01 / INICT01 – Network interface modules used when bridging INFI 90 to higher‑level networks or HMIs.

- ABB IMASI03 – Analog input (4–20 mA) module for hard‑wired signals that don’t come over serial.

- ABB IMDSI14 – Digital input module; often paired when mixed I/O and Modbus devices coexist in the same cabinet.

- ABB INNPM22 – Power supply module for the INFI 90 rack; ensure capacity headroom when adding comm processors.

A maintenance lead recently told me they swapped an old gateway for an IIMCP01 to simplify fault‑finding—less external wiring, and all diagnostics visible from their usual INFI 90 tools.

Installation & Maintenance

- Cabinet & rack – Install in a clean, ventilated control cabinet; keep ambient within 0–60 °C and avoid condensation.

- Wiring – Use shielded twisted pair for RS‑485; terminate the last node and apply biasing as per ABB guidance. Keep serial and power cables separated from VFD output cables.

- Grounding – Bond cable shields at one end (typically the controller end) to prevent ground loops; verify cabinet earth integrity.

- ESD care – Handle the module with proper ESD protection; de‑energize the rack before insertion or removal.

- Commissioning – Set baud rate, parity, and node addresses to match field devices; validate polling lists and watch error counters/LEDs during FAT/SAT.

- Routine maintenance – Inspect connectors annually, clean dust with dry air, and review comm diagnostics. If firmware/EPROMs are used, keep revision control aligned with your site standard.

Quality & Certifications

- CE marked; UL Recognized (typical for ABB INFI 90/Harmony modules)

- Manufactured under ISO 9001 quality systems

- RoHS status may vary by production date; we can confirm per lot before shipment

- Standard warranty: 12 months from delivery (365 days)

Reviews

There are no reviews yet.