Description

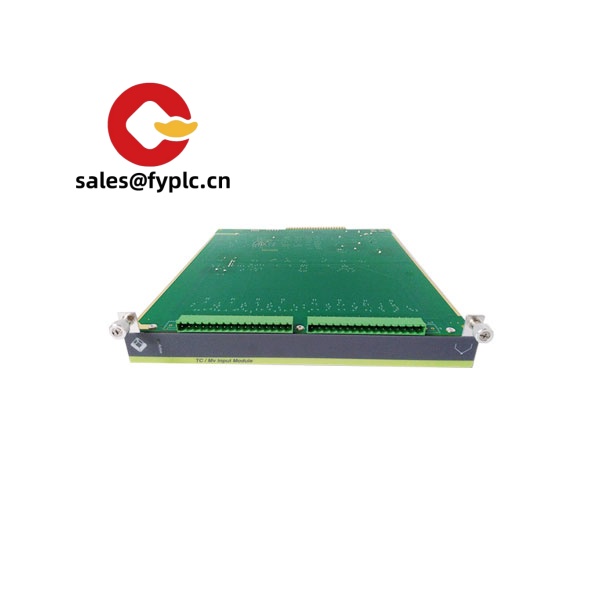

METSO IOP310 – I/O Processor Module for METSO DNA Distributed Control Systems

The METSO IOP310 is an I/O processor module used in METSO DNA racks to supervise field I/O channels and coordinate data exchange with the controller. From my experience, this is the card that quietly keeps the analog and digital points flowing reliably between the plant floor and the automation server. You might notice that it doesn’t take field wiring directly—its job is to manage the I/O cards over the backplane, support diagnostics, and keep things deterministic. In many cases it’s installed in redundant pairs to allow online maintenance without a process stop.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

One thing I appreciate is how straightforward the swap procedure is. A maintenance lead at a pulp mill told us, “Replacing an IOP310 took under 10 minutes—redundancy kept the loop under control the whole time.”

Key Features

- Backplane-managed I/O processing – Supervises analog and digital I/O modules via the METSO DNA rack backplane; no direct field wiring on the card.

- Deterministic data handling – Typically ensures stable scan times and synchronized updates to the controller, which helps with tight control loops.

- Redundancy-ready – Often deployed in pairs for bumpless switchover during maintenance or fault conditions.

- Integrated diagnostics – Status LEDs and system health flags help technicians quickly localize issues down to the I/O segment.

- Hot serviceability – In many cases, supports online replacement when a redundant mate is present, cutting downtime to near zero.

- Control room friendly – Operates in typical 0–55°C environments found in standard automation cabinets.

Technical Specifications

| Brand / Model | METSO IOP310 |

| HS Code | 853890 (Parts suitable for use with electrical control gear) |

| Power Requirements | Backplane‑powered from METSO DNA rack; no external supply required |

| Dimensions & Weight | Single‑slot plug‑in module for METSO DNA subrack; compact, lightweight card format |

| Operating Temperature | 0 to 55 °C (control cabinet environment) |

| Signal I/O Types | Supervises mixed AI/AO/DI/DO via associated I/O cards; no direct field termination on IOP310 |

| Communication Interfaces | METSO DNA backplane system bus; configuration and diagnostics accessible via engineering workstation |

| Installation Method | Plug‑in to DNA I/O rack; typically secured with card guides/latch; ESD‑safe handling recommended |

Related or Supporting Products

- METSO DNA AI16 Analog Input Module – 16‑channel AI card used for 4–20 mA/voltage inputs; the IOP310 manages its cycle timing and diagnostics.

- METSO DNA AO8 Analog Output Module – 8‑channel AO card for actuator/valve control; pairs well with redundant IOPs in critical loops.

- METSO DNA DI32 Digital Input Module – High‑density discrete input card for machine status and interlocks.

- METSO DNA DO16 Digital Output Module – Discrete output card driving solenoids and contactors via interposing relays.

- METSO DNA Rack Power Supply – Provides regulated backplane power to IOP and I/O cards; keeping a spare PSU on hand typically reduces recovery times.

- METSO DNA Subrack/Backplane – The chassis hosting IOP and I/O modules; confirm slot assignment and keying before installation.

Installation & Maintenance

- Cabinet & environment – Install in a clean, dry control cabinet with adequate ventilation. Keep ambient within 0–55 °C and avoid vibration where possible.

- Wiring practice – Field wiring lands on the associated I/O terminal units, not on the IOP310. Separate analog and digital wiring and maintain shield grounding per site standard.

- Redundancy – If fitted as a redundant pair, perform online replacement on the failed side only and verify switchover on the engineering station before returning to normal.

- ESD safety – Use wrist straps and handle by edges. Inspect connector fingers for debris before insertion.

- Routine checks – Review diagnostic logs quarterly, verify scan times, and confirm firmware/parameter versions match site standards. Dust the card guides and slots during scheduled outages.

- Firmware/config backups – Keep a current image of the configuration on the engineering workstation; it typically speeds up card replacement and validation.

Quality & Certifications

- Manufacturer-grade quality consistent with METSO DNA hardware

- Typical conformity: CE; RoHS-compliant build is common for control-room hardware

- Warranty: 365 days (repair/replace)

If you’re refreshing an existing DNA rack or building a spare set, the IOP310 usually slots straight in with minimal engineering—just confirm rack slotting, redundancy role, and that your I/O card mix matches the intended configuration.

Reviews

There are no reviews yet.