Description

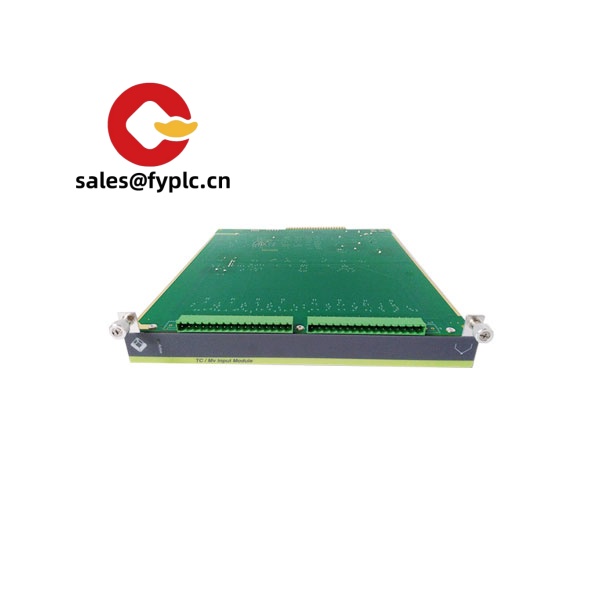

ABB IOR810K02 – Rugged I/O Interface/Relay Module for Industrial Control Racks

The ABB IOR810K02 is a rack-mounted I/O interface module, typically used to extend digital I/O capacity in ABB control systems. From my experience, plants use it where reliable, isolated I/O or relay interfacing is needed between field devices and the controller backplane. The “K02” denotes a later hardware revision, which in many cases brings improved stability and wider compatibility across installed ABB racks.

You might notice that users choose the IOR810K02 when they want a straightforward way to add channel isolation, status indication, and backplane-powered operation without reworking cabinet layouts. It plays nicely in expansion racks, and maintenance teams like the clear LEDs and simple, tool‑friendly replacement procedure.

Our Order Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Rack-mounted I/O expansion – Adds digital interface/relay functionality directly on the ABB backplane, keeping wiring tidy.

- Isolated channels – Channel-to-channel and channel-to-system isolation helps reduce noise and ground loop issues in mixed-signal cabinets.

- Backplane-powered – Typically supplied from the system 24 VDC backplane; no separate field power for the module itself.

- Status LEDs – Clear, per-channel indicators simplify commissioning and quick fault checks.

- K02 hardware revision – Later revision that, in many cases, improves reliability and lifecycle alignment with current ABB systems.

- Service-friendly design – Front access for module swap; supports standard ABB mounting bases for efficient field replacement.

Technical Specifications

| Brand / Model | ABB IOR810K02 |

| HS Code | 8538.90 (Parts for control panels/boards) |

| Power Requirements | Backplane-supplied, 24 VDC nominal (typical for ABB rack I/O modules) |

| Dimensions & Weight | Compact rack module; typical ABB card size ~120 × 45 × 100 mm; approx. 0.25 kg |

| Operating Temperature | 0 to +55 °C (typical for ABB control modules) |

| Signal Input/Output Types | Isolated digital interface/relay I/O, used for field contact interfacing and signal conditioning |

| Communication Interfaces | System backplane bus; no front-port communication required in normal operation |

| Installation Method | Plugs into ABB I/O base/terminal unit in a control rack; DIN-rail or panel-mounted cabinet per system standard |

Note: Details above reflect typical values used across ABB rack I/O modules for planning and comparison. If you’re matching an existing rack, share the rack type and base/terminal unit, and we’ll verify exact compatibility before shipment.

Related or Supporting Products

- ABB IOR810K01 – Earlier hardware revision of the same family; often backward compatible in the same rack.

- ABB CI810 / CI810B – Communication interface module used to connect S800-style I/O to controllers.

- ABB TU810 / TB810 – Terminal units/bases for I/O modules; pick the base type to match your wiring and shielding approach.

- ABB AI810 / AO810 – Analog input/output modules for process signals (4–20 mA/0–10 V), if you’re expanding beyond digital/relay I/O.

- ABB DI810 / DO810 – Digital input/output modules for 24 VDC signals, commonly installed alongside relay/interface modules.

One thing I appreciate is how these pieces line up mechanically, so cabinet retrofits are usually quick. A maintenance lead recently told us, “Swapping to the K02 unit took less than 10 minutes, and the status LEDs made the loop check painless.”

Installation & Maintenance

- Cabinet & mounting – Install in a clean, dry control cabinet with DIN-rail or rack per ABB guidelines; leave clearance for airflow and service access.

- Power & wiring – Use the system backplane for power; route field wiring via the designated terminal unit. Keep field and power lines separated to reduce interference.

- Grounding & shielding – Apply single-point grounding; land shield drains on the appropriate terminals according to your plant EMC practice.

- ESD handling – Treat the module as ESD-sensitive; use a grounded wrist strap during installation or swap.

- Routine checks – Periodically verify LED indicators and channel function during planned shutdowns; inspect terminals for loosened screws or corrosion.

- Firmware/compatibility – Where applicable, match module revision (K02) with the controller and rack firmware baseline. We can help confirm before dispatch.

Quality & Certifications

- Manufacturer quality systems typically aligned to ISO 9001

- CE compliance and RoHS conformity expected for this product class

- UL/CSA recognition on many ABB I/O modules; specific file on request

- Standard manufacturer warranty practices apply; our coverage: 365 days

Reviews

There are no reviews yet.