Description

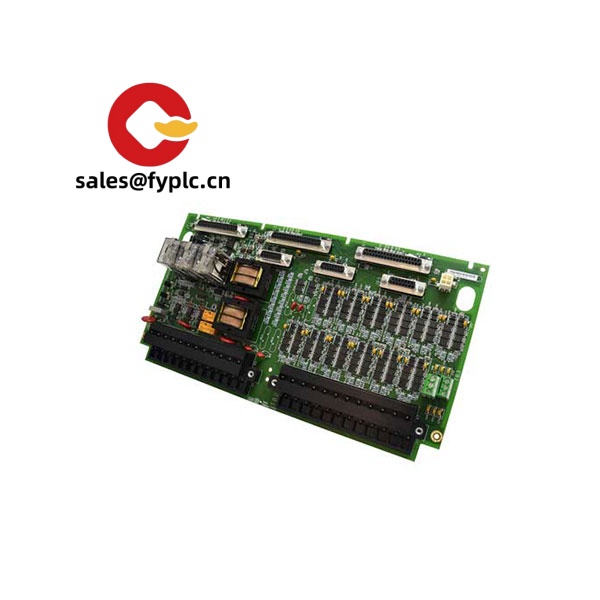

GE IS200EROCH1AED – Excitation Regulator Output Board for EX2100 / Mark VI Systems

The GE IS200EROCH1AED is an Excitation Regulator Output board typically used within EX2100 and Mark VI-series excitation systems to translate regulator commands into precise power bridge firing outputs. From my experience, this module sits at the heart of reliable field control—providing isolated, multi-channel firing signals and robust feedback paths so the generator stays stable across load swings and grid events. One thing I appreciate is how it integrates cleanly through the Innovation Series backplane, which usually makes swap-out and commissioning fairly straightforward for service teams.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express Options: FedEx, UPS, DHL

Key Features

- Firing signal output for SCR bridges – Converts regulator control into isolated fiber-optic firing pulses for the exciter power bridge, which in many cases improves stability under fast transients.

- Backplane integration (Innovation Series) – Plugs into the Mark VI/EX2100 rack, minimizing external wiring and keeping service times shorter.

- Isolated channels and diagnostics – Isolation typically protects the control core from power side disturbances; onboard status indicators help with quick fault tracing.

- Redundancy-friendly design – Works within typical redundant rack architectures, so you can maintain availability during maintenance or partial failures.

- Industrial temperature tolerance – Designed for control cabinets in plant environments; typically supports 0–60°C with proper ventilation.

- Field-proven in utility and heavy industry – Frequently used on steam and gas turbine generator exciters where predictable response is essential.

Technical Specifications

| Brand / Model | GE – IS200EROCH1AED (Excitation Regulator Output Board) |

| HS Code | 853890 (Parts for electrical control/switchgear) |

| Power Requirements | Supplied via Mark VI/EX2100 backplane; typically +5 VDC and auxiliary rails from rack (low-power board-level consumption) |

| Signal I/O Types | Fiber-optic firing outputs to SCR bridge; differential/logic control and status via backplane; onboard status LEDs |

| Communication Interfaces | Innovation Series/Mark VI backplane interface (no external Ethernet on this board) |

| Operating Temperature | Typically 0 to +60°C with cabinet ventilation, 5–95% RH non-condensing |

| Dimensions & Weight | Approx. 233 × 160 mm Eurocard footprint; light-weight PCB assembly (rack-mounted) |

| Installation Method | Rack-mounted in EX2100/Mark VI control cabinet, keyed connectors; follow slot designation for H1A/H1 revisions |

| Typical Application | Generator excitation control (steam/gas turbines), stable field current regulation, coordinated bridge firing |

Related or Supporting Products

- IS200EDEX – Exciter power supply/drive interface board; pairs with EROC to condition drive power and feedback.

- IS200EPCT – Potential/voltage sensing card for the exciter; provides bridge or field voltage feedback to the regulator.

- IS200EISB – Interface/Signal board; aggregates I/O between regulator core and power stage in many EX2100 frames.

- IS200TREG – Turbine regulator/control board commonly found in Mark VI racks; hosts core control logic communicating with output boards.

- IS200EROCH1A (earlier revisions) – Functionally similar to IS200EROCH1AED; differences are typically component revisions and minor hardware updates.

You might notice that plants often keep an EROC and EDEX on the shelf together—field techs tell us those two boards are the usual pair when troubleshooting bridge firing irregularities or sporadic undervoltage alarms.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, vibration-controlled enclosure; keep ambient within 0–60°C. Provide steady airflow; avoid obstructing adjacent card slots.

- Wiring & handling – Use proper ESD protection. Verify backplane seating and keyed guides before power-up. Fiber-optic leads to the power bridge should have minimum bend radius and clean ferrules.

- Power-up checks – Confirm status LEDs, bridge permissives, and that regulator setpoints match the site configuration. In most cases, commissioning via the Mark VI toolbox will validate firing patterns.

- Routine maintenance – Quarterly visual inspection for dust and connector looseness; clean with dry, oil-free air. Review event logs. Firmware/config baselines should be archived and updated under change control.

- Safety – De-energize and lock out both control power and exciter bridge sources before removal. Residual energy may remain in the DC link; verify discharge.

Quality & Certifications

- Certifications – Typically conforms to CE and RoHS requirements for industrial control assemblies; GE manufacturing is commonly ISO 9001 certified.

- Compliance context – UL recognition may apply at the system level; this board is intended for use within the approved EX2100/Mark VI cabinet.

- Manufacturer Warranty – 365-day warranty from shipment on workmanship and functionality under normal use.

From site feedback, IS200EROCH1AED seems to be a stable drop-in when replacing earlier EROC revisions—the transition usually comes down to matching the rack slot and confirming the firing enable logic in the project file. If you’re refreshing spares, pairing this with updated fiber leads has saved technicians a second cabinet visit more than once.

Reviews

There are no reviews yet.