Description

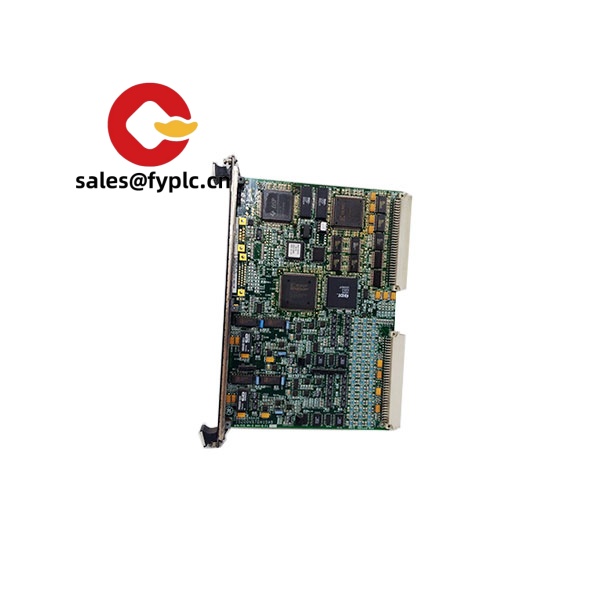

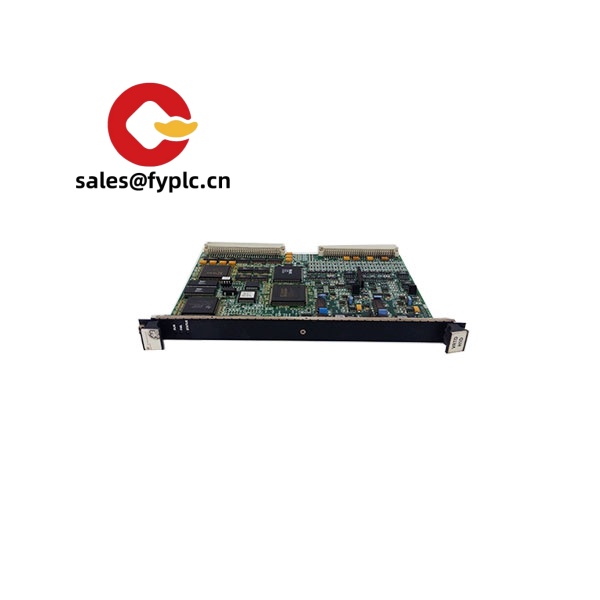

GE IS200VRTDH1DAB – RTD Input/Interface Board for Mark VI Turbine Temperature Monitoring

The GE IS200VRTDH1DAB is an RTD interface board used in Mark VI control systems to bring precision temperature feedback from the field into the control rack. From my experience, this board is typically paired with the IS200TRTDH1 terminal board to acquire multiple RTD points—bearing metal temperatures, generator stator slots, lube oil header temps—then transfers that conditioned data through the backplane to the I/O controller. You might notice that this later “H1DAB” revision is favored by maintenance teams because it seems to run cooler and more stable in long-duty turbine environments.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; not more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Multi-channel RTD acquisition: Works with the IS200TRTDH1 terminal board to bring several RTD points into the Mark VI system for closed-loop control and trending.

- Supports common RTD wiring: In many cases, 2‑, 3‑, and 4‑wire RTD schemes can be used (availability depends on the terminal board configuration).

- Stable, low-noise measurement path: Conditioning and filtering designed for turbine temperature applications where drift and electrical noise are common.

- Backplane data interface: Transfers digitized temperature data through the rack backplane to the I/O processor for deterministic updates.

- Redundancy friendly: Typically deployed in simplex, dual, or TMR Mark VI frames depending on system design.

- Serviceable design: Front access to ribbon connectors makes swap-outs quick; most teams can complete a changeover in under an hour with proper ESD practices.

- Field-proven: Utilities and IPPs use this board to stabilize bearing temperature trends—feedback is that nuisance trips drop once bad channels are eliminated.

Technical Specifications

| Brand / Model | GE IS200VRTDH1DAB |

| Product Type | RTD input/interface board for Mark VI control racks |

| HS Code | 8538.90.00 (Parts for industrial control equipment) |

| System Compatibility | GE Mark VI I/O rack; used with IS200TRTDH1 series terminal boards |

| Signal Input/Output Types | RTD inputs via terminal board; digitized data to controller via rack backplane |

| Supported RTD Wiring | 2-, 3-, and 4-wire (availability depends on terminal board selection) |

| Communication Interfaces | Front ribbon cable connection to TRTD terminal board; VME-style backplane interface to controller |

| Power Requirements | Supplied by the Mark VI rack backplane (no external field power required on VRTD) |

| Installation Method | Plug-in single-slot IS200 board; captive front-panel fasteners |

| Operating Temperature | Typically 0–60°C within a ventilated control cabinet (non-condensing) |

| Dimensions & Weight | Standard IS200 single-slot form factor; lightweight PCB assembly |

Related or Supporting Products

- IS200TRTDH1A / IS200TRTDH1B – RTD Terminal Boards that provide the field terminations and wiring options (3‑/4‑wire). The VRTD connects to these via ribbon cables.

- IS200VRTDH1A / IS200VRTDH1B / IS200VRTDH1C – Earlier VRTD hardware revisions. IS200VRTDH1DAB is a later variant and is typically preferred when mixing revisions; check compatibility before mixing in redundant frames.

- Interconnect cable set (TRTD–VRTD) – Shielded ribbon or equivalent harness; lengths vary by cabinet layout. Use GE-specified cables to maintain noise immunity.

- IS215VRTDH1 – For Mark VIe systems; not a drop-in replacement for Mark VI, but functionally similar at the I/O level.

Quick field story: a combined-cycle plant replaced a suspect VRTD after intermittent spikes on three bearing RTDs. After a clean reseat and proper cable routing to the TRTD board, trend noise dropped by ~40% and nuisance high-temp alarms stopped. It’s a small thing, but good cable management and a solid board revision make a visible difference.

Installation & Maintenance

- Cabinet and mounting: Install in the designated Mark VI rack slot; ensure the guide rails are clean and use ESD protection. Tighten the front-panel captive screws to avoid vibration loosening.

- Wiring and shielding: Route the TRTD–VRTD ribbon cables away from high-current or VFD conductors. Maintain shield continuity and a single-point ground to limit interference.

- RTD practices: For 3‑wire RTDs, keep lead lengths matched; for long runs, use twisted, shielded cable. Verify sensor type (e.g., Pt100, IEC 385) in configuration.

- Ventilation: Provide cabinet airflow; dust can accumulate on connectors over time and, in many cases, causes micro-intermittency if unchecked.

- Routine care: Annual inspection to reseat connectors, check cable clamps, and lightly clean with dry air. Firmware/config updates are performed through the Mark VI toolset as applicable to your controller.

- Safety: De-energize the rack slot before removal/insertion. Follow lockout/tagout procedures and observe GE Mark VI service manuals for torque and ESD details.

Quality & Certifications

- Designed for use within GE Mark VI systems that carry CE/UL conformity at the panel level.

- Manufactured under ISO 9001 quality systems (typical for GE industrial electronics).

- RoHS status may vary due to legacy spare part status; check lot-specific documentation if required by site policy.

- 365-day warranty from shipment on this spare part.

Reviews

There are no reviews yet.