Description

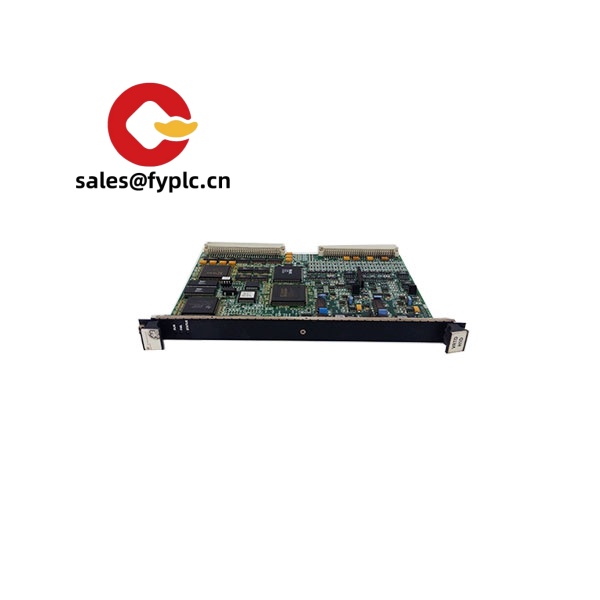

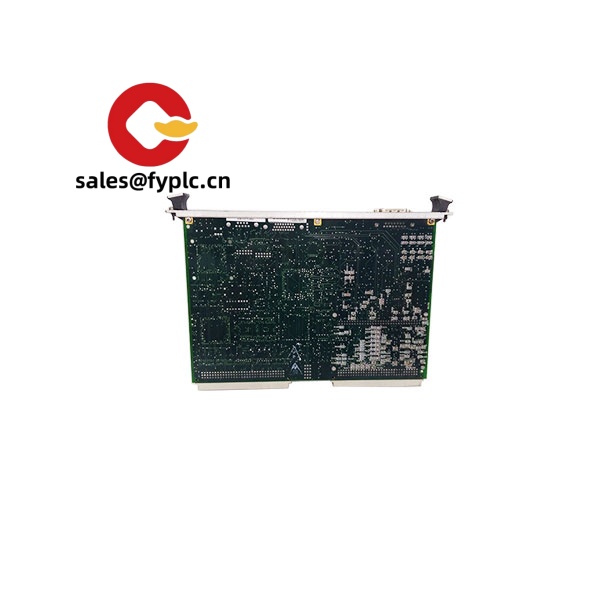

GE IS200VSVOH1BDC – Servo Valve Output Board for Mark VI Turbine Control

The GE IS200VSVOH1BDC is a Servo Valve Output (VSVO) board used in Mark VI turbine control systems to drive electro‑hydraulic servo valves with stable, precise current. From my experience, this board is the piece you rely on when you need tight hydraulic actuator control for steam or gas turbine governing, stop/stop valves, or IGV positioning. It typically sits in the VME rack and communicates over the backplane, while the field wiring terminates on the paired terminal board (TSVO). One thing I appreciate is how consistently it maintains bipolar current to the valve coils, even under noisy plant conditions.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; full payment before delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Servo current outputs (bipolar) – Designed to drive electro‑hydraulic servo valves with high stability, typically up to ±200 mA per channel.

- Backplane integration – Interfaces via the Mark VI VME backplane, reducing extra wiring and keeping loop timing tight.

- Onboard diagnostics – Health/status and loop feedback help maintenance teams pinpoint wiring or valve issues faster.

- Deterministic control – Fast, repeatable update rates suitable for turbine governing, IGVs, and critical stop valves.

- Redundancy-friendly – Works within simplex, dual, or TMR Mark VI architectures in many cases.

- Revision detail – The H1BDC revision typically indicates a later hardware build; it seems to be offered with protective coating options depending on lot.

- Field-proven – Many sites report drop‑in replacement behavior with minimal tuning required after swap.

Technical Specifications

| Brand / Model | GE IS200VSVOH1BDC (Servo Valve Output Board, Mark VI) |

| HS Code | 8538.90 (Parts suitable for electrical control equipment) |

| Power Requirements | Supplied via VME backplane; logic +5 VDC and analog rails (typically ±15 VDC) provided by the rack power supply |

| Dimensions & Weight | 6U VME form factor; approx. 233 × 160 mm; weight typically < 0.7 kg |

| Operating Temperature | 0 to 60 °C (typical control cabinet conditions) |

| Signal Input/Output Types | Multiple bipolar current outputs for EHSV actuation (commonly up to ±200 mA); onboard D/A with diagnostic feedback |

| Communication Interfaces | VME backplane interface to Mark VI controller |

| Installation Method | Plug-in 6U VME board; mates to its terminal board in the panel (TSVO) for field wiring |

Where it fits best

Typical applications include steam turbine EHC servo control (main stop/intercept valves), gas turbine fuel or IGV servo loops, and position control where stable current drive is mandatory. One maintenance supervisor told us they swapped a VSVO board during an outage—loop tuning stayed within spec and the unit was back at load in under an hour.

Related or Supporting Products

- IS200TSVOH1A – Mating terminal board for VSVO; provides field wiring terminals and filtering for servo outputs.

- IS200VAICH1A – Analog input board often used alongside servo loops for feedback and process variables.

- IS200VTURH1B – Turbine speed/phase interface used in Mark VI racks; complementary for speed‑related control functions.

- Mark VI VME Power Supply (various part numbers) – Provides +5 V and ±15 V rails to the I/O boards; choose capacity according to slot population.

- Note: Replacement variants of VSVO (e.g., later H1B builds) are typically form‑fit compatible; coating and minor component changes may differ by lot.

Installation & Maintenance

- Cabinet & environment – Install in a clean, dry control cabinet meeting Mark VI rack standards; keep ambient 0–60 °C with adequate ventilation.

- Wiring – Route servo valve leads to the TSVO terminal board. Use twisted pairs and proper shielding to minimize noise. Verify polarity for bipolar current outputs.

- Grounding – Bond shield drains at one end only (typically cabinet end) to avoid ground loops.

- ESD care – Handle the board with wrist strap and ESD mat; avoid touching component leads and edge connectors.

- Commissioning – After insertion, check backplane seating and standoffs. Run loop checks: command ramp, null bias, and current feedback verification.

- Routine maintenance – Quarterly connector inspection, light dust removal with dry air, and review diagnostic logs. Firmware/config in Mark VI should be backed up before any changes.

- Spare strategy – In many cases, plants keep one spare VSVO per panel section due to the criticality of servo loops.

Quality & Certifications

- CE and UL compliance are typically applicable for Mark VI assemblies in industrial environments.

- Manufactured under ISO 9001 quality systems at the OEM level.

- RoHS status may vary by revision; H1B‑series boards often include protective coatings for harsher atmospheres.

- Standard warranty: 365 days from delivery.

If you’re replacing a legacy VSVO or migrating within the Mark VI family, this IS200VSVOH1BDC tends to be a straightforward fit. You might notice cleaner current stability after reseating connectors and re‑nulling the valve; that small step often pays back with smoother actuator response.

Reviews

There are no reviews yet.