Description

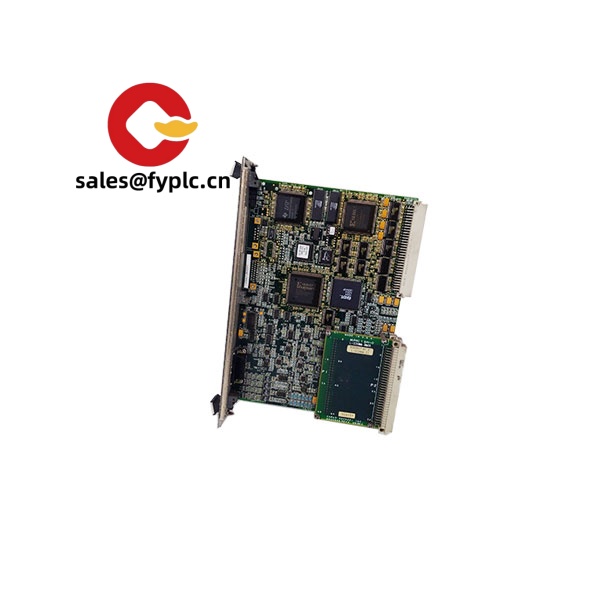

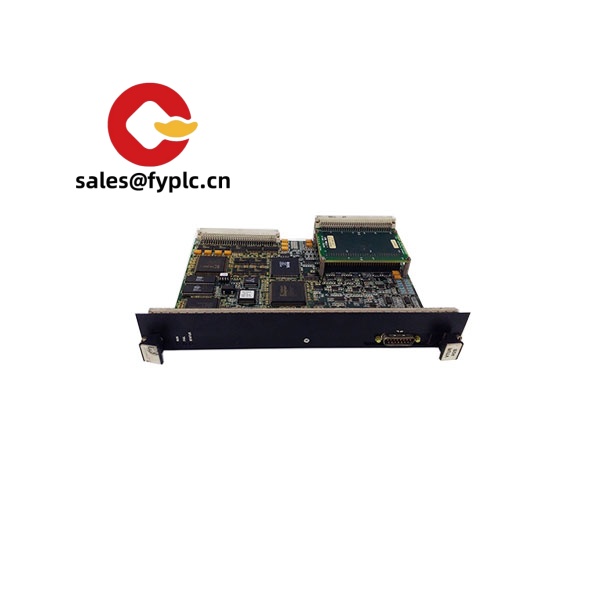

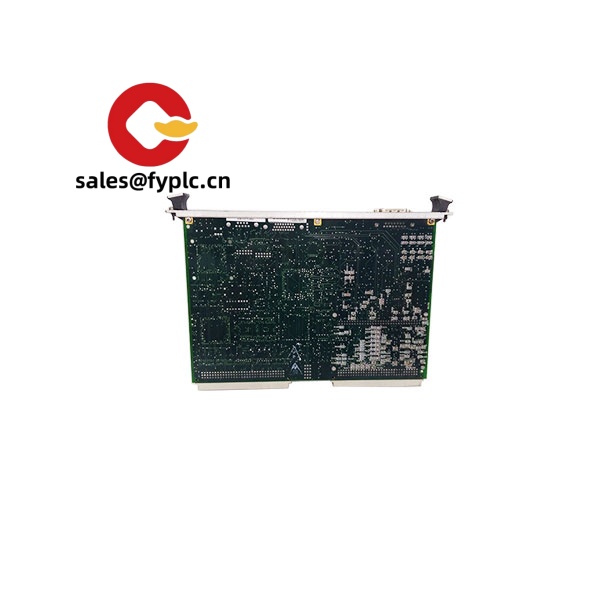

GE IS200VTURH2BAC — VTUR Turbine Terminal Board for Mark VI/VIe Speed Sensing and Protection

The GE IS200VTURH2BAC is a VTUR series terminal board used in Mark VI and, in many cases, Mark VIe turbine control cabinets to bring in turbine speed signals and route them to the protection/control layer. From my experience, this board is typically paired with the PTUR I/O pack (Mark VIe) or associated Mark VI controller hardware to support redundant speed pickup inputs and overspeed protection logic. You might notice that it’s chosen when plants want clean, stable speed signals and straightforward panel wiring without adding extra converter modules.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Redundant turbine speed inputs: Typically accommodates three independent speed pickup channels for TMR-based protection schemes. Helps reduce nuisance trips through voting.

- Compatible with passive MPUs and prox sensors: In many cases supports standard turbine magnetic pickups; proximity probe compatibility is system-dependent and defined by the mated I/O pack.

- Pairs with PTUR I/O pack: Designed to work with GE PTUR (Mark VIe) for overspeed/protection functions and speed measurement, simplifying cabinet layout and serviceability.

- Panel-friendly wiring: Screw-terminal style landing points and clear channel separation make commissioning quicker and cable routing tidier.

- Noise-conscious layout: Practical grounding and shield terminations help keep low-level speed signals clean in high-EMI turbine compartments.

- Built for TMR architectures: Supports typical two-out-of-three logic at the system level when used with the appropriate controller and protection packs.

Technical Specifications

| Brand / Model | GE IS200VTURH2BAC (VTUR terminal board) |

| System Compatibility | Mark VI and typically Mark VIe turbine control systems; pairs with PTUR I/O pack or equivalent controller interface |

| Signal Input / Output Types | Up to 3x turbine speed pickup channels (passive magnetic pickup; proximity probe support depends on I/O pack); discrete status/relay interface via system-level hardware |

| Communication Interfaces | Mates directly with GE PTUR I/O pack (Mark VIe) or connects via controller cabling in Mark VI panels; no standalone fieldbus on the terminal board itself |

| Power Requirements | Typically sourced from the associated I/O pack or control backplane (nominal 24–28 VDC environment; the VTUR board itself has minimal power demand) |

| Operating Temperature | Typically 0 to +60 °C in a ventilated control cabinet (exact range depends on the cabinet design and I/O pack specification) |

| Installation Method | Panel/bulkhead mounting inside the control cabinet; shielded twisted-pair recommended for speed inputs; separate from high-voltage routing |

| Dimensions & Weight | Standard GE terminal-board format; medium-size PCB suitable for Mark VI/VIe racks (weight typically around 1 kg) |

| HS Code | 8538.90 (Parts for switching/protection panels; final classification may vary by destination and configuration) |

Related or Supporting Products

- GE PTUR I/O Pack (Mark VIe): Mounts on VTUR to provide the processing, diagnostics, and Ethernet interface for speed/overspeed functions.

- GE IS200VTURH1B series: Earlier/alternate VTUR variants; differences are typically hardware revision and channel handling—check sensor compatibility when mixing.

- GE IS215VPROH2B (VPRO protection): Commonly used for protection/voting functions in Mark VI systems; integrates with trip logic.

- GE TREG / TRPG / TRES terminal boards: Trip interface boards used to drive turbine trip solenoids in TMR configurations.

- Speed Sensors (MPUs / Proximity Probes): Use matched pickup types and cable lengths per turbine OEM guidelines to keep phase and amplitude consistent across channels.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated control cabinet. Maintain adequate airflow around I/O packs mounted on the board.

- Wiring practice: Use shielded twisted-pair for speed pickups. Terminate shields at a single point (usually cabinet ground) to reduce ground loops. Keep sensor wiring away from VFD or solenoid power cables.

- Grounding: Ensure cabinet and board ground bonding are sound. A stable reference typically improves low-level speed signal quality.

- Commissioning: Verify pickup gaps and polarity. With PTUR/VPRO tools, check channel amplitude and frequency at slow-roll and rated speed. Calibrate overspeed thresholds per site procedures.

- Maintenance: Periodically retorque terminals, inspect for oxidation, and clean dust using dry, oil-free air. Firmware updates (where applicable) are performed on the I/O pack, not the passive VTUR board.

- Safety: De-energize relevant circuits before terminal work. Follow lockout/tagout and turbine OEM speed-sensing practices.

Field feedback: “After swapping to IS200VTURH2BAC with PTUR packs, the speed signals looked cleaner and we stopped seeing intermittent overspeed alarms during startup. The wiring layout was more forgiving than our older setup.”

Quality & Certifications

- Manufacturing quality: GE industrial-grade PCB with conformal coating on most revisions.

- Certifications: Typically aligns with CE and UL practices for control panels; RoHS status can vary by revision and production year.

- Warranty: 365 days coverage on supplied unit.

If you’re replacing an existing VTUR or mixing revisions (H1/H2), I usually suggest confirming sensor type and overspeed trip integration with your current PTUR/VPRO setup. A quick I/O checklist upfront tends to save hours during outage.

Reviews

There are no reviews yet.