Description

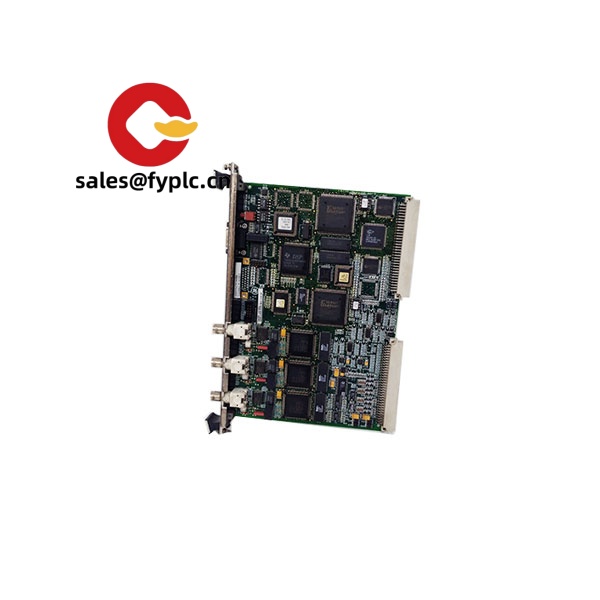

GE IS215VCMIH2BE – VME Communication Interface for Mark VI Turbine Control Networks

The GE IS215VCMIH2BE is a VME Communication Interface (VCMI) module used in Mark VI turbine control systems. From my experience, this board typically sits in the VME rack and handles controller-to-network communications—linking the controller, the I/O subsystem, and the plant network (UDH/IONet) with robust, deterministic performance. You might notice that the H2 and “E” revision indicate a later hardware/firmware release within the VCMI family, often preferred when standardizing on a stable Mark VI platform.

Typical use cases include upgrading legacy racks to improve network reliability, building a hot-standby (TMR or dual) controller architecture, or replacing aging interface cards during a planned outage. One thing I appreciate is the straightforward VME form factor—installation is fast, and service teams usually recognize the layout and LED status approach right away.

Order Placement Process and Guarantees

- Warranty: 365 days (parts replacement or repair, subject to evaluation)

- Delivery: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- VME Communication Interface for Mark VI: Designed to bridge the controller and plant networks within GE Mark VI racks.

- Ethernet-based UDH/IONet connectivity: Typically provides 10/100Base‑T ports for controller/HMI communications and I/O network links.

- Backplane integration: Communicates over the VME backplane (P1/P2), simplifying wiring and reducing cabinet clutter.

- Status LEDs and diagnostics: Front-panel indicators help technicians verify link, health, and activity at a glance during commissioning.

- Redundancy-friendly: Commonly used in dual or TMR configurations to support high availability in gas, steam, and combined-cycle units.

- Industrial build: IS215 series versions are often conformal-coated, which in many cases improves reliability in humid or dusty environments.

Technical Specifications

| Brand / Model | GE IS215VCMIH2BE (VCMI module for Mark VI) |

| HS Code (reference) | 8538.90 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | Backplane powered via VME (typically 5 VDC rail) |

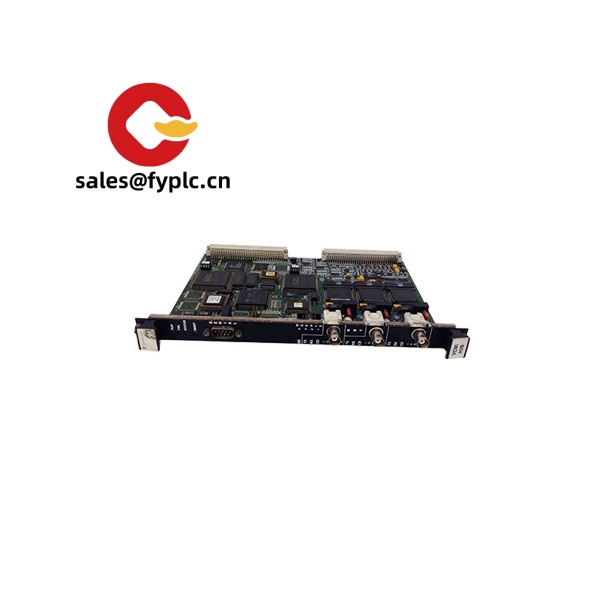

| Dimensions & Weight | 6U VME form factor (approx. 233 × 160 mm); typical module weight ~0.5–0.8 kg |

| Operating Temperature | Typically 0 to +60 °C when installed in a conditioned control cabinet |

| Signal I/O Types | VMEbus backplane; RJ‑45 Ethernet (10/100); service serial port (RS‑232) in many cases |

| Communication Interfaces | VME master/slave role for rack communications; Ethernet UDH/IONet for controller/HMI and I/O networks |

| Installation Method | Slides into VME slot with front-panel retention screws; ESD handling required |

| System Compatibility | GE Mark VI control systems (VME-rack based). Check site firmware and rack layout for revision matching. |

Related or Supporting Products

- GE IS200VCMIH2B – Similar VCMI function in the IS200 series; often considered when a non-conformal coated variant is acceptable.

- GE UCVE/UCVA Controllers (e.g., IS215UCVEM, IS215UCVFH) – CPU/controller boards commonly paired with VCMI in Mark VI racks.

- Mark VI I/O Terminal Boards (e.g., IS200TBAIH1C for analog) – Interface boards on the I/O network side; selection depends on the point list.

- VME Rack Components (power supply, backplane, filler panels) – Ensure slot spacing, airflow, and power capacity suit H2‑series modules.

A maintenance lead at a combined-cycle site told us the IS215VCMIH2BE “dropped in cleanly” when standardizing Ethernet link speeds across UCVE controllers, with the only adjustment being network port labeling for the new revision.

Installation & Maintenance

- Cabinet environment: Install in a Mark VI VME rack within a clean, conditioned control cabinet; maintain steady airflow and avoid blocked front panels.

- Wiring/Networking: Use shielded Cat5e/Cat6 for Ethernet runs per plant standard. Label UDH/IONet ports clearly to prevent crossover during outages.

- ESD & handling: Wear an ESD strap, handle by the faceplate/edges, and de-energize the rack before insertion/removal unless your site procedure allows live-swap.

- Firmware alignment: Match board firmware/boot versions to the controller pack. In many cases, sites keep a mirrored spare imaged to the current project.

- Routine checks: Inspect connectors and faceplate screws at outages, clear dust with dry air, verify LED health after network changes, and document MAC/port assignments.

- Redundancy: For dual or TMR architectures, confirm each VCMI’s network path, managed-switch settings (if used), and heartbeat monitoring before returning the unit to service.

Quality & Certifications

- Certifications: GE Mark VI hardware is typically CE-marked; UL recognition often applies at the system level. RoHS status can vary by build date.

- Manufacturer policy: GE provides documentation and lifecycle notes by revision; field deployments usually follow site MOC procedures for firmware compatibility.

- Our warranty: 365-day coverage for this module; units are tested prior to shipment with ESD-safe packing.

Reviews

There are no reviews yet.