Description

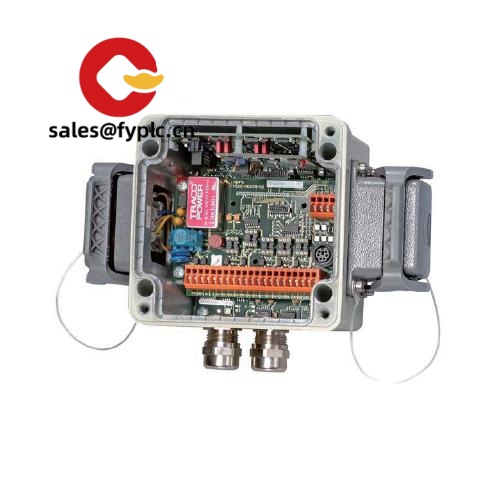

EPRO MMS6823R – Redundancy-Oriented System Module for MMS 6000 Machinery Monitoring

The EPRO MMS6823R is a plug‑in system module for the MMS 6000 machinery monitoring platform, designed to support high availability in continuous‑process environments. From my experience, plants choose the R variant when they want robust redundancy on critical compressor or turbine trains, but don’t want to touch the rest of the rack configuration. You might notice that it slots into the MMS 6000 rack just like other MMS modules and integrates with the system backplane, so changeovers are typically quick and don’t require re‑wiring the entire cabinet.

Typical use cases include steam/gas turbines, critical pumps, and petrochemical compressors where continuous monitoring is non‑negotiable. One thing I appreciate is how it plays nicely with existing MMS 6000 cards—vibration, speed, or position—so you can keep your protection logic intact while boosting resilience.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: In-stock items ship in about 1 week; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

From a recent customer on a refinery upgrade: “We swapped the MMS6823R during a short window and didn’t have to power down the entire rack—saved us a shift.” That seems to be the common story when teams need a fast, low‑risk refresh.

Key Features

- Redundancy-ready system module – Built for high-availability MMS 6000 racks, typically used to maintain continuous monitoring on critical assets.

- Hot‑swappable design – Slide in/out without disturbing adjacent cards, which helps reduce downtime during maintenance.

- Backplane integration – Interfaces directly with the MMS 6000 system bus, so configuration and diagnostics remain consistent with existing modules.

- System status indication – Front‑panel LEDs and status signaling make health checks quick during rounds.

- Industrial temperature capability – Suitable for control cabinets near rotating equipment; in many cases used in utility and chemical environments.

- Service/maintenance access – Typically provides a service interface for commissioning and checks, which keeps site work predictable.

Technical Specifications

| Brand / Model | EPRO MMS6823R (MMS 6000 series) |

| HS Code | 9032.89 – Other automatic regulating or controlling instruments |

| Power Requirements | Powered via MMS 6000 backplane; compatible with redundant rack supply arrangements (typ. low‑watt module) |

| Operating Temperature | Typical industrial range (commonly 0 to +60 °C in cabinet installations) |

| Signal I/O Types | Backplane system bus; status indication via front panel; system status/relay signaling depending on rack configuration |

| Communication Interfaces | MMS 6000 internal bus; in many cases a service/maintenance serial interface is available for setup |

| Installation Method | Plug‑in (hot‑swappable) MMS 6000 rack module; front‑panel retention screws; shielded wiring per MMS cabinet practice |

Note: Exact ratings can vary by MMS 6000 rack configuration and module revision; if you share the rack BOM or a photo of the front label, we can verify specifics before shipping.

Related or Supporting Products

- EPRO MMS 6000 Rack & Base – Required backplane and mechanics for MMS modules.

- EPRO MMS6110 – Speed/tachometer monitoring module for overspeed and phase reference.

- EPRO MMS6312 – Vibration monitoring/protection module, commonly paired with proximity probes or accelerometers.

- EPRO MMS6220 – Displacement/position monitoring for shaft and thrust measurements.

- EPRO PR6423 / PR9268 – Proximity probe systems and accessories frequently used with MMS channels.

- EPRO MMS6822 – Power supply/system module used in non‑redundant setups; MMS6823R is preferred when higher availability is required.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated 19″ control cabinet. Maintain airflow around the rack and keep ambient within the recommended industrial range.

- Wiring & grounding: Use shielded twisted pair for any service/serial links; bond shields at the designated MMS grounding points to minimize noise.

- Hot‑swap practice: Place the system in a safe state as defined by plant procedures. Insert/remove the module slowly to avoid connector wear; secure with front‑panel screws.

- Routine checks: Visually inspect connectors and front LEDs during rounds. Verify status signaling to the DCS/ESD quarterly, especially in redundant arrangements.

- Firmware/configuration: If a service port is provided, back up settings before changes. In many cases, a quick checksum or revision check is enough during maintenance windows.

- Cleaning: Dust the front panel with a soft antistatic brush; avoid solvents on labels and windows.

Quality & Certifications

- CE compliant design for industrial control environments

- RoHS compliant components in most recent revisions

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days from delivery

Reviews

There are no reviews yet.