Description

EPRO MMS3125022-020 – Keyphasor/Tachometer Module for MMS 3000 Machinery Monitoring

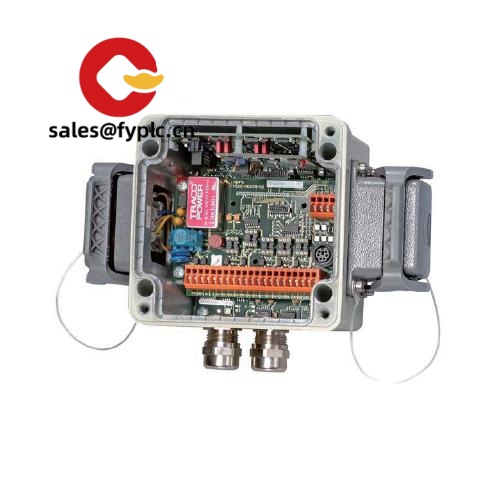

The EPRO MMS3125022-020 is a plug-in speed and phase reference module for the MMS 3000 rack, typically used as a Keyphasor/tachometer channel to provide reliable shaft speed and phase information for vibration monitoring and protection. From my experience, it’s the kind of module you add when you need stable speed tracking for 1× synchronous amplitude/phase, order tracking, or overspeed alarms, without overcomplicating the rack design. It pairs well with eddy-current proximity probes (e.g., EPRO PR642x series) and, in many cases, supports TTL/logic tach inputs as well.

One thing I appreciate is how it integrates straight into the MMS 3000 backplane—no extra power wiring—and gives you alarm relays and buffered tach signals that are easy to route to your DCS or condition monitoring software. You might notice that plants often select this option when they want consistent phase reference across multiple vibration modules in the same rack.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Keyphasor/tachometer function – Provides a stable speed/phase reference for synchronous vibration analysis and machine protection.

- Compatible with proximity probes – Typically used with EPRO PR642x probes and appropriate drivers for non-contact speed pickup from a keyway or notch.

- Buffered tach output – Convenient for feeding analyzers or historians without loading the sensor signal.

- Alarm relays – Configurable overspeed/logic relays to support trip or annunciation in most cases.

- MMS 3000 rack integration – Powered and networked through the backplane; no external supply at the module face.

- Front-panel status indicators – Quick visual check of channel OK, alarms, and signal presence.

- Typical two-channel variant – The “022-020” option set is commonly used where dual speed/phase pick-ups or redundant reference are desired.

Technical Specifications

| Brand / Model | EPRO MMS3125022-020 (MMS 3000 series) |

| HS Code | 903180 (Measuring/monitoring instruments, other) |

| Power Requirements | Powered via MMS 3000 rack backplane; no separate external power to the module |

| Signal Input Types | Non-contact proximity probe Keyphasor input; supports tach/phase reference sensing; TTL/logic tach input is common in this series |

| Signal Output Types | Buffered tach/Keyphasor output; alarm relay contacts for overspeed/logic functions |

| Communication Interfaces | MMS 3000 internal rack bus for system integration |

| Installation Method | Plug-in 19″ MMS 3000 rack module; wiring via rack terminals; front-panel indicators |

| Dimensions & Weight | Standard MMS 3000 plug-in form factor (Eurocard-style); lightweight module suitable for control cabinet mounting |

| Operating Temperature | Typically 0 to +55 °C when installed in a ventilated control cabinet |

Related or Supporting Products

- EPRO MMS3120 – Vibration monitor channel; pairs with MMS3125022-020 for 1× phase-referenced measurements.

- EPRO MMS3123 – Additional vibration/axial position channel options (varies by rack configuration).

- EPRO MMS3110 – Power supply/backplane services module for the MMS 3000 rack.

- EPRO PR6423 / PR6424 proximity probes – Common non-contact probes for Keyphasor and radial vibration pickup.

- EPRO CON0x drivers – Probe drivers to condition PR642x sensors for rack inputs.

Quick note from projects we’ve delivered: a dual-probe Keyphasor setup (redundant or 90° apart) with MMS3120 vibration cards gives very stable phase reference and cleaner 1× diagnostic plots, especially on compressors and gearboxes.

Installation & Maintenance

- Cabinet & rack: Mount in an MMS 3000 19″ rack inside a clean, ventilated control cabinet. Keep ambient heat low; forced ventilation is helpful when other heat sources (VFDs, soft starters) are nearby.

- Wiring: Use shielded cables for proximity probes and maintain good grounding practices. Route low-level sensor cables away from power lines to minimize noise pickup.

- Probe setup: Set correct probe gap (typically per PR642x datasheet) and ensure a clear once-per-rev target. A painted mark or milled notch usually works best.

- Safety: De-energize machinery before mechanical adjustments. Verify relay logic before connecting to trip circuits—do a dry test first.

- Routine checks: Periodically verify speed reading against a handheld tachometer, inspect probe cabling/anchors, and confirm relay setpoints after shutdowns or maintenance.

Quality & Certifications

- CE compliant industrial monitoring module (typical for MMS 3000 series)

- RoHS compliant where applicable

- Manufactured under ISO 9001 quality systems

- Manufacturer’s warranty: 12 months

If your application needs a strict overspeed trip chain or multiple phase references on the same shaft, the MMS3125022-020 seems to be a sensible, low-maintenance option that integrates cleanly with existing MMS 3000 racks.

Reviews

There are no reviews yet.