Description

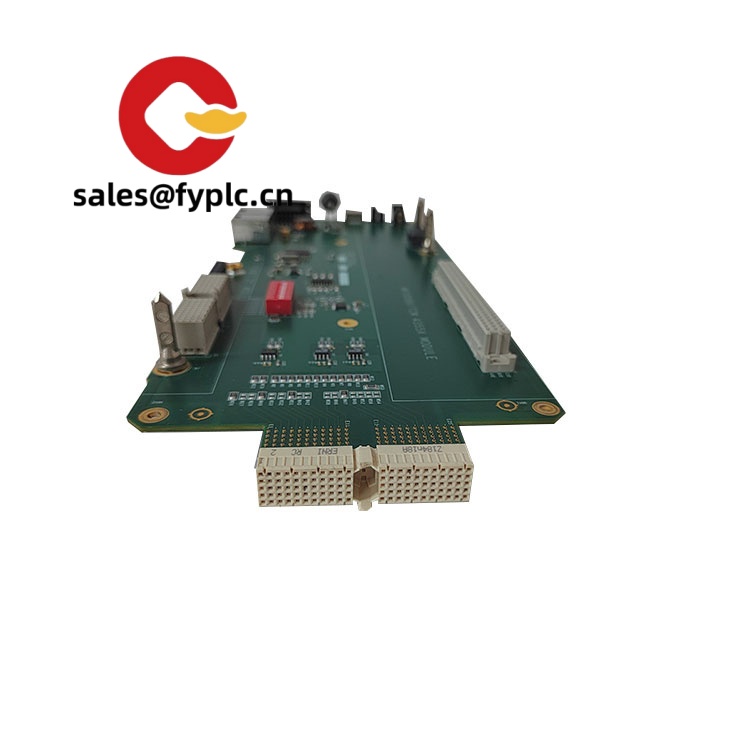

BACHMANN MP226 – Compact M1 processing module for reliable real‑time control

The BACHMANN MP226 slots into the M1 system and takes care of the time‑critical control and coordination tasks you typically need on production lines, power and energy skids, marine auxiliaries, and wind assets. From my experience, teams like it because it’s straightforward to deploy in existing M1 racks, keeps cycle times tight, and plays nicely with standard IEC 61131‑3 workflows. You might notice that it’s happiest when paired with Bachmann’s DI/DO/AI/AO modules—let the MP226 handle the logic and networking while the I/O modules interface with field signals.

One thing I appreciate is the platform consistency: if you already maintain M1 cabinets, the MP226 feels familiar—same backplane concept, same service approach, and typically the same tooling (SolutionCenter). In many cases, that means faster retrofits and fewer surprises during FAT/SAT.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- M1 system integration: Installs on the Bachmann M1 backplane for fast data exchange with I/O and communication modules.

- Deterministic control: Suitable for real‑time control loops and coordinated machine sequences in most cabinet‑mounted environments.

- Familiar engineering workflow: Typically configured and maintained via Bachmann SolutionCenter with IEC 61131‑3 languages.

- Service‑friendly diagnostics: Clear status LEDs and structured fault reporting help shorten troubleshooting time during commissioning.

- Robust industrial build: Designed for 24 V DC control cabinets; stable in electrically noisy environments when grounded correctly.

- Flexible networking: M1 backplane communications by default; front‑side service/network ports and serial access are present on many MP2xx variants.

Technical Specifications

| Brand / Model | BACHMANN MP226 (M1 system module) |

| HS Code | 8537.10 (Programmable control panels/boards) |

| Power Requirements | 24 V DC via M1 backplane (typical for Bachmann M1 modules) |

| Dimensions & Weight | Single‑slot M1 form factor (compact cabinet footprint) |

| Operating Temperature | Typically 0…+60 °C in a ventilated control cabinet |

| Signal Input/Output Types | System processor; field I/O handled by M1 DI/DO/AI/AO/CNT modules on the same rack |

| Communication Interfaces | M1 system backplane; front service/network and serial access on many MP2xx variants (exact ports depend on the specific variant) |

| Installation Method | DIN‑rail cabinet installation with M1 backplane connector; proper grounding recommended |

Real‑world usage

A packaging OEM told us they swapped an older M1 CPU for an MP2xx module like the MP226 during a weekend retrofit. Because the wiring and backplane stayed intact, they were back in production by Monday—only a short revalidation of the PLC tasks and the HMI tags was needed.

Related or Supporting Products

- BACHMANN MPC240 / MPC270 – Higher‑performance M1 controller modules when you need more headroom for complex logic or higher network traffic.

- BACHMANN DI2xx / DO2xx / AI2xx / AO2xx – Digital and analog I/O families for connecting sensors, actuators, and process signals alongside MP226.

- BACHMANN M1 power supply modules (24 V DC) – Stable backplane power for MP226 and accompanying I/O in the same rack.

If you’re matching an existing cabinet spec, send a quick photo or part list of the current M1 rack; we can confirm slot compatibility and suggest a like‑for‑like or capacity upgrade path.

Installation & Maintenance

- Cabinet & ventilation: Mount on DIN rail in a closed, ventilated control cabinet. Keep ambient within the stated industrial range and avoid direct heat sources.

- Wiring & grounding: Use clean 24 V DC supply, segregate I/O and power cabling, and bond PE to cabinet ground to minimize EMC issues.

- Backplane & slotting: Seat the module firmly on the M1 backplane. From my experience, a gentle visual check of the connector alignment prevents intermittent faults.

- Safety: De‑energize the cabinet before inserting/removing modules. Observe ESD handling for all M1 hardware.

- Routine maintenance: Quarterly dust removal with dry air, verify terminal tightness, review diagnostic logs. Plan firmware updates during scheduled downtime and keep a rollback image.

- Backup: Keep current project backups in your version control; it seems to save hours if you ever replace a module under time pressure.

Quality & Certifications

- Designed for industrial control applications; typically conforms to CE requirements.

- UL and RoHS compliance are commonly available for Bachmann M1 modules; documentation can be provided with the shipment.

- Manufactured under ISO 9001 quality systems.

- Manufacturer’s standard warranty applies; our supply warranty is 365 days as stated above.

Need a quick confirmation on MP226 compatibility with your current rack and firmware? Share the existing module list and firmware revision—typically we can verify and quote lead time within the same day.

Reviews

There are no reviews yet.