Description

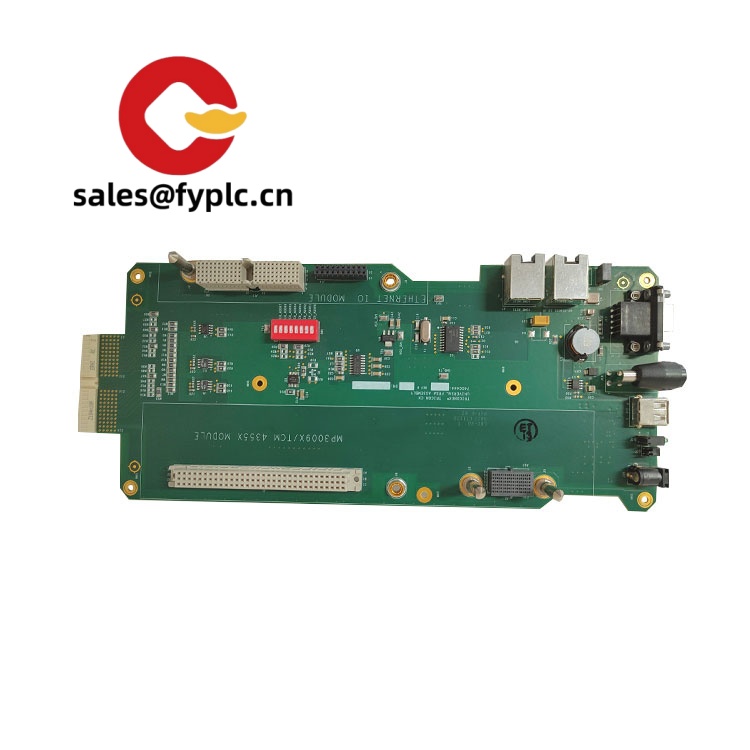

TRICONEX MP3009X + TCM 4355X – Main Processor and Communication Module for Tricon TMR Safety Systems

The TRICONEX MP3009X and TCM 4355X pairing is designed for Tricon TMR safety controllers where high availability and deterministic communication really matter. The MP3009X serves as the triplicated main processor, while the TCM 4355X typically handles plant network connectivity and peer links. From my experience, this combo is a common drop‑in for brownfield upgrades—keeping the safety logic on a proven architecture, yet making it easier to talk to modern DCS/SCADA via Ethernet and serial protocols.

Typical use cases include ESD and F&G systems in oil & gas, turbine protection in power plants, and high‑integrity interlocks in chemical units. One thing I appreciate is how the TMR design lets you replace a single module online (with procedures) without forcing a unit shutdown—customers often report fewer production interruptions because of that.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- TMR main processing (MP3009X) – Triplicated architecture with voting increases fault tolerance and helps maintain SIL3 safety when integrated as part of a Tricon system.

- Communication gateway (TCM 4355X) – Typically provides Ethernet and serial connectivity for DCS/SCADA links, peer‑to‑peer messaging, and engineering access.

- Online module replacement – In many cases, modules can be replaced under load following Triconex procedures, minimizing downtime.

- Deterministic execution – Stable scan performance and predictable diagnostics behavior, which is valuable in interlock and shutdown logic.

- Broad integration options – Commonly used with Modbus TCP/RTU and TriStation tooling; interface sets can vary by firmware revision.

- Proven field history – These part families are well‑established in hydrocarbon processing and power generation, which tends to simplify MOC and validation.

Technical Specifications

| Brand / Model | TRICONEX MP3009X (Main Processor) + TCM 4355X (Communication Module) |

| System Compatibility | Tricon TMR safety controller platforms (slot‑based chassis); exact slotting per Triconex manual |

| HS Code | 8538.90 (Parts suitable for use with apparatus of 8537) |

| Power Requirements | Backplane‑powered from Tricon chassis power supply (nominal 5 VDC distribution) |

| Operating Temperature | Typically 0 to 60 °C (consult specific revision datasheet for exact limits) |

| Signal I/O Types | No direct field I/O on MP3009X/TCM 4355X; interfaces via Tricon backplane and TCM communication ports |

| Communication Interfaces | TCM 4355X typically provides Ethernet (10/100Base‑TX) and serial ports (RS‑232/RS‑485); supports TriStation access, Modbus TCP/RTU, and peer messaging depending on firmware |

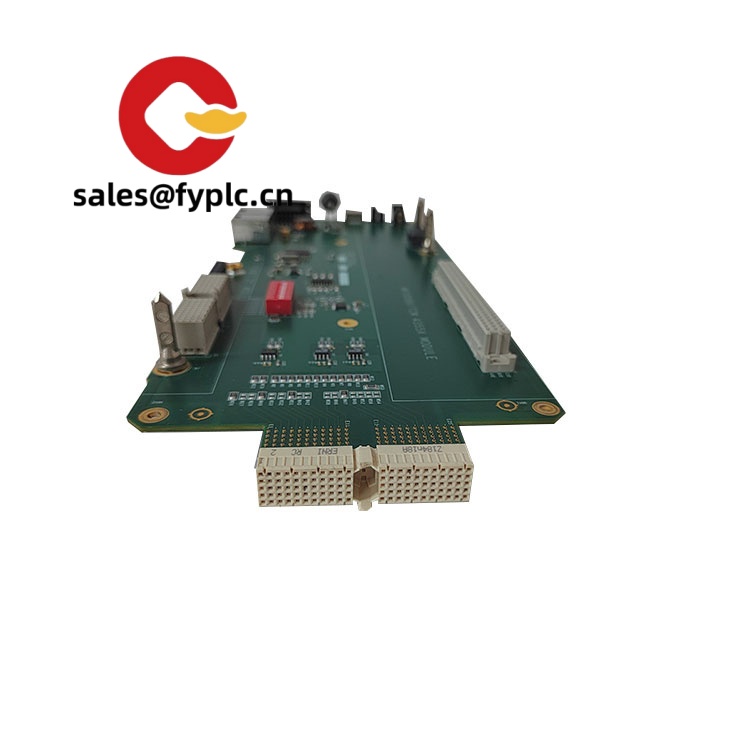

| Installation Method | Plug‑in modules for Tricon chassis; install as triplicated sets in designated slots; secure card guides and backplane latch |

| Form Factor / Dimensions & Weight | Standard Tricon plug‑in form factor; dimensions and mass per Triconex mechanical specification for the target chassis |

Related or Supporting Products

- TRICONEX MP3008 – Earlier main processor variant; often used where installed base standardizes on the 3008 firmware stream.

- TRICONEX TCM 4353 / 4354 – Communication module variants; interface mix and firmware features differ (for example, specific serial channel counts or protocol options).

- TRICONEX 8110/8111 chassis and power supplies – Required for housing and powering MP/TCM modules in TMR configuration.

- TRICONEX I/O cards (e.g., 3721 AI, 3700A DI, 3625 DO) – Field I/O modules that pair with MP3009X for process signal handling.

Installation & Maintenance

- Cabinet & environment – Mount the Tricon chassis in a clean, dry control cabinet with adequate ventilation; maintain clear airflow above and below the cards.

- Power & grounding – Use the specified Tricon power supplies; maintain single‑point grounding and segregate instrument earth from noisy power returns where practicable.

- Wiring & segregation – Keep Ethernet and serial cables away from high‑voltage runs; for serial, match termination/baud and shield strategy as per site EMC practices.

- Slotting – Install three MP3009X modules and three TCM 4355X modules in their designated triplicated slots; verify backplane connectors are fully seated.

- Commissioning – Load and verify application with TriStation; confirm diagnostics are healthy (no votes failed) and comms links are stable before energizing field I/O.

- Routine care – Review diagnostics and event logs weekly; back up the project after approved changes; clean dust with antistatic methods during planned outages.

- Firmware management – Align firmware revisions across the triplicated set; updates should follow MOC and be performed during a maintenance window.

- Online replacement – In most cases permitted by Triconex, but follow the manual strictly: confirm healthy majority, isolate the affected leg, and document the action.

Quality & Certifications

- Certified SIL3 at the system level (IEC 61508) when used within an approved Tricon configuration

- CE marking and UL/cUL recognition are commonly available for Triconex modules

- RoHS/Reach status can vary by module revision and region; confirm per serial/PN if required by your site standards

- Manufacturer warranty per Triconex policy; additional 365‑day coverage provided by us

You might notice that engineering teams migrating older peer links to Ethernet tend to prefer the TCM 4355X because it simplifies DCS handshakes. A maintenance lead from a Gulf Coast refinery told me the online replacement capability “saved a weekend turnaround” after a single leg fault—no emergency shutdown, just a controlled swap and re‑vote.

Reviews

There are no reviews yet.