Description

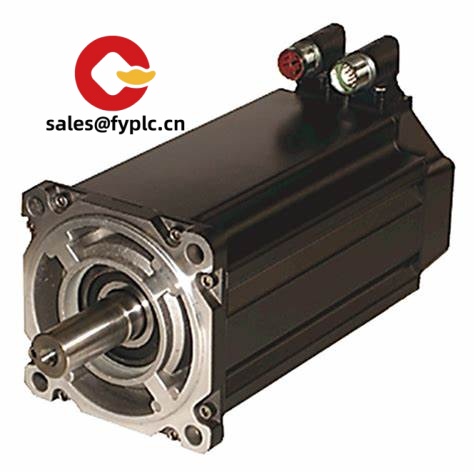

Allen-Bradley MPL-B320P-MJ74AA – MP-Series Low Inertia Servo Motor for Fast, Precise Motion

The Allen‑Bradley MPL-B320P-MJ74AA is part of the MP‑Series Low Inertia (MPL) servo family, designed for high‑response indexing, contouring, and synchronized axes on Kinetix platforms. From my experience, this model hits a sweet spot for packaging, printing, and pick-and-place cells where quick acceleration and tight position holding are essential. You might notice that it pairs cleanly with Kinetix 5500/5700 and legacy 6000 systems, keeping wiring straightforward and commissioning predictable.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Shipping: express options via FedEx, UPS, or DHL

Key Features

- Low‑inertia rotor design – delivers fast acceleration/deceleration for short cycle times and crisp following.

- ‘P’ stack length – a balanced choice for torque density without oversizing the frame, typically good for compact machines.

- High‑resolution feedback (J74 option) – stable velocity and position control with Kinetix drives; tuning tends to be quick.

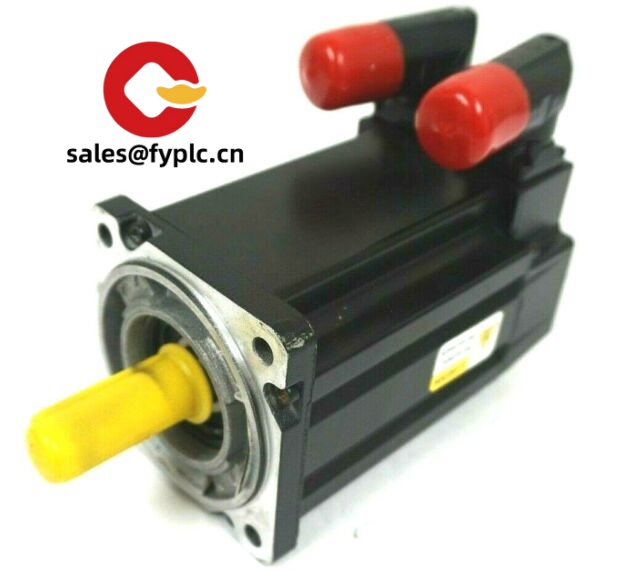

- Integrated holding brake (M option) – 24 VDC brake for vertical axes or emergency stop holding, reducing mechanical risk.

- IP65 when mated – sealed connectors and shaft seal help in dusty or splash-prone environments.

- IEC-style square‑flange mounting – straightforward face-mounting in most servo-ready machine frames.

- Kinetix ecosystem compatibility – typically used with 2094 (Kinetix 6000), 2198 (Kinetix 5500), or 2199 (Kinetix 5700) drives.

Technical Specifications

| Brand / Model | Allen‑Bradley MPL-B320P-MJ74AA (MP‑Series Low Inertia AC servo motor) |

| HS Code | 8501.52 (AC multi‑phase motors, >750 W and ≤75 kW) |

| Voltage / Drive Bus Class | Typically 200–240 V‑class winding for “320” variants; powered via compatible Kinetix servo drives |

| Feedback & Brake | High‑resolution feedback (J74 option); 24 VDC holding brake (M option) |

| Protection / Cooling | IP65 when correctly mated; natural convection (fanless) |

| Operating Temperature | 0…40 °C ambient (typical for MP‑Series; de‑rate above 40 °C) |

| Dimensions & Weight | B‑frame with ~100 mm square flange; ‘P’ stack length; weight varies by exact option set (refer to MPL drawing for precise values) |

| Signal I/O Types | 3‑phase motor power plus feedback connector; 24 VDC brake leads (if brake present) |

| Communication Interfaces | Not applicable on motor; communication is handled by the servo drive |

| Installation Method | IEC square‑flange face mount; use matched Allen‑Bradley power/feedback cables for IP65 sealing |

Related or Supporting Products

- MPL-B310P-MJ74AA – Same frame with a lighter torque/winding; useful where rapid dynamics matter more than peak torque.

- MPL-B330P-MJ74AA – Higher torque in the same B‑frame; a common step‑up if the 320 winding runs near its limits.

- 2198-xxxx (Kinetix 5500) – EtherNet/IP Integrated Motion; great mid‑range pairing and compact panels.

- 2199-xxxx (Kinetix 5700) – Higher power and multi‑axis scalability; typically used on larger machines.

- 2094-xxxx (Kinetix 6000) – Legacy SERCOS systems still widely installed; this motor remains a compatible fit in many cases.

- 2090-xxNPM / 2090-xxNFx cables – Factory power and feedback cables to maintain performance and IP rating.

Installation & Maintenance

One thing I appreciate is how predictable these MP‑Series motors are during commissioning. For best results, mount on a rigid, machined surface and keep cable runs short and shielded. In most cases, you’ll get a clean tune with Kinetix auto‑tuning and only minor manual tweaks.

- Environment: 0–40 °C ambient, non‑condensing; allow airflow around the motor body for natural convection.

- Cabinet/Drive: Follow drive bus class requirements (typically 200–240 V‑class for “320”); bond shields at both ends.

- Wiring: Use matched 2090 power/feedback cables; ensure connector seals are fully seated for IP65.

- Grounding: Star‑ground topology and low‑impedance bonding minimize EMI and encoder noise.

- Safety: Engage the 24 VDC brake only as a holding device; it’s not a dynamic stop.

- Routine care: Inspect connectors quarterly, check shaft seal for wear, clean fins/housing, and review drive firmware updates during scheduled downtime.

A packaging OEM told us they swapped an older axis to this MPL-B320P-MJ74AA and, after a quick retune, shaved ~8% off cycle time just from better acceleration. That seems to be typical when replacing higher‑inertia motors.

Quality & Certifications

- Certifications: CE, UL/cUL (typical for MP‑Series), RoHS compliant

- Protection: IP65 at the shaft and connectors when properly mated

- Warranty: 365 days (repair/replace under normal use)

Reviews

There are no reviews yet.