Description

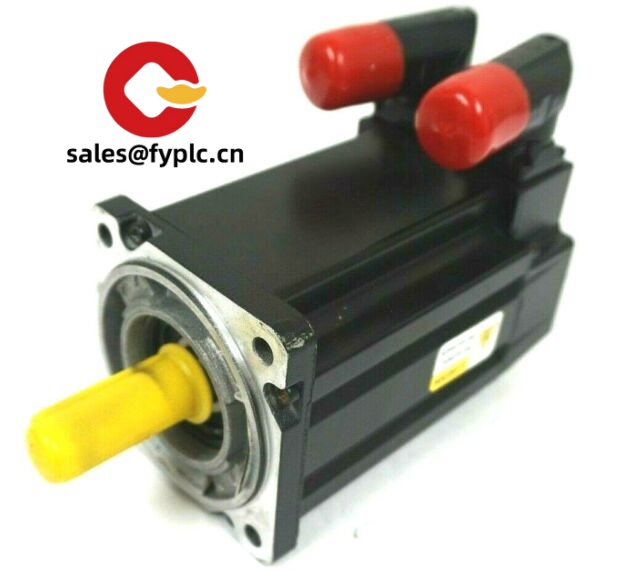

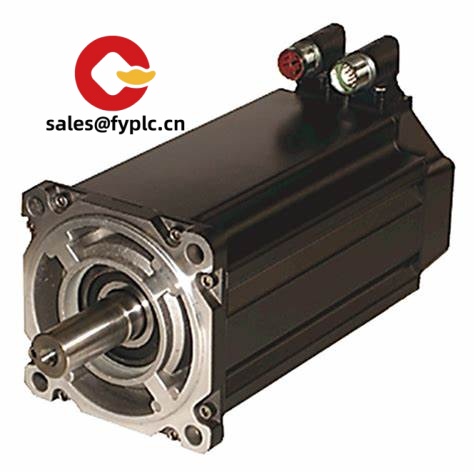

Allen-Bradley MPL-B320P-SJ72AA — Low‑Inertia AC Servo Motor for Fast, Precise Motion

The Allen-Bradley MPL-B320P-SJ72AA is a Kinetix low‑inertia servo motor designed for quick acceleration, tight position control, and compact machine layouts. It typically pairs with 200–240 V Kinetix drives in applications like packaging axes, pick‑and‑place heads, small indexing tables, feeders, and light material handling. One thing I appreciate is how the B‑frame MPL motors hit that sweet spot of torque density and responsiveness without demanding oversized drives or cabling.

From my experience, the “B320P” winding is a popular choice when you need short cycle times and repeatable starts/stops on 230 V systems. You might notice this configuration commonly includes a keyed, straight shaft and a high‑resolution feedback option, making tuning on Kinetix 5500/5700 drives pretty straightforward in most cases.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than 1 month at the latest

- Payment method: 50% advance payment, full payment before delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Low‑inertia rotor – Enables rapid accel/decel, reducing index times and improving throughput on multi-stop motion.

- 200–240 V class winding – Works seamlessly with Kinetix 200 V‑class servo drives; a practical fit for 230 V panels.

- High‑resolution feedback (per suffix) – Stable low‑speed control and repeatable positioning; simplifies servo tuning in many cases.

- Compact B‑frame footprint – Square‑flange design drops into tight machines and modular cells without reworking the mechanics.

- Keyed, straight shaft – Reliable power transmission with standard couplings and gearheads; less guesswork on the shop floor.

- Robust environmental sealing – Housing typically meets industrial washdown/dust ingress needs when mated with proper connectors and shaft seal.

- Standard 2090-series cabling – Quick to source and replace; keeps maintenance predictable.

Technical Specifications

| Brand / Model | Allen-Bradley MPL-B320P-SJ72AA (Kinetix MPL low‑inertia AC servo motor) |

| HS Code | 8501.52 (AC servo motor, >0.75 kW ≤75 kW; classification may depend on rated output) |

| Power Requirements | 200–240 VAC class via compatible Kinetix servo drive (3‑phase power to motor U/V/W) |

| Operating Temperature | 0 to +40°C ambient (non‑condensing, typical) |

| Signal I/O Types | 3‑phase power (U/V/W), motor frame ground; encoder feedback (per suffix); optional 24 VDC brake |

| Communication Interfaces | N/A at motor; control/fieldbus handled by the Kinetix drive (e.g., EtherNet/IP, SERCOS depending on drive) |

| Installation Method | Square‑flange face mount (B‑frame); keyed straight shaft; horizontal or vertical mounting |

| Dimensions & Weight | B‑frame, ~100 mm class square‑flange; stack length corresponds to “320” series (consult datasheet for exact size/weight) |

| Protection | Industrial duty; IP54 to IP65 achievable with correct connectors/shaft seal (configuration‑dependent) |

Related or Supporting Products

- Kinetix 5500 (2198‑Hxxxx) – 200 V‑class compact multi‑axis drives; a common pairing for MPL‑B motors.

- Kinetix 5700 (2198‑xxxx) – Higher power and flexibility for larger machines; still 200/400 V‑class options.

- 2098‑DSD Ultra3000 – Legacy drives often found in field retrofits; MPL‑B motors are widely used here.

- 2090‑series power/feedback cables – Factory‑terminated cabling sets; helps maintain EMC and sealing.

- MPL‑B310P‑… / MPL‑B330P‑… – Same family, different stack/torque points if you need less or more torque.

- VPL‑B… (Kinetix VP Low‑Inertia) – Newer single‑cable servos with digital feedback; a modern alternative when redesigning panels.

A packaging OEM told us they moved from an MPL‑B315P to an MPL‑B320P to shave cycle time on an indexing turret; tuning was minimal, but the acceleration margin improved enough to hit their throughput target. That seems to be a common pattern with B320 in light‑to‑medium axes.

Installation & Maintenance

- Mounting – Face‑mount to a rigid, aligned surface; verify shaft concentricity and use properly sized keyed couplings or gearheads.

- Cabling – Use shielded 2090‑series power/feedback cables; bond shields 360° at connectors; maintain bend radius and strain relief.

- Thermal considerations – Allow airflow around the housing; if running near continuous torque, provide extra ventilation or duty‑cycle reserve.

- Grounding & EMC – Earth the motor frame; route motor power separately from feedback and I/O to reduce noise.

- Safety – Lockout/tagout before servicing. If equipped with a brake, wire 24 VDC through a safe circuit as required by your risk assessment.

- Routine maintenance – Inspect couplings and mounting bolts periodically; check connectors for contamination; clean with a dry cloth; verify brake release/hold if present; keep servo drive firmware current and retune if the load changes.

Quality & Certifications

- Manufacturer compliance typically includes CE and cULus; RoHS conformant; produced under ISO 9001 quality systems.

- Warranty: 365 days (repair/replace per standard RMA process).

Reviews

There are no reviews yet.