Description

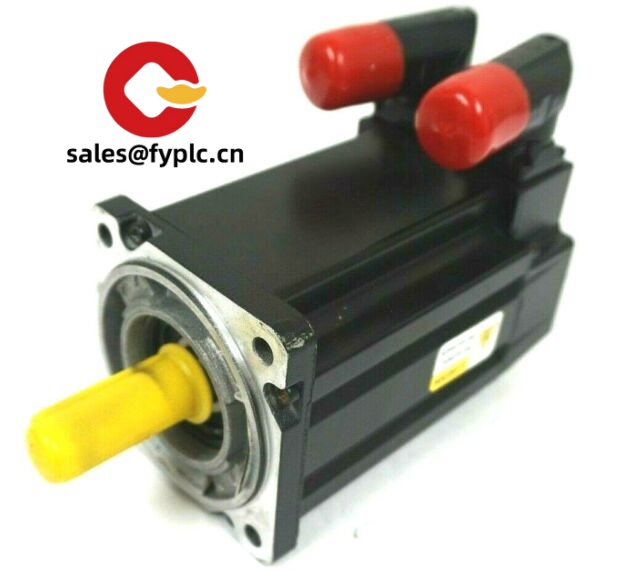

Allen‑Bradley MPL-B330P-MJ72AA Low-Inertia Servo Motor for Precise, High‑Speed Axes

The Allen‑Bradley MPL-B330P-MJ72AA is part of the MP-Series Kinetix low‑inertia servo family. From my experience, this model is a solid fit when you need fast acceleration, tight positioning, and smooth motion on packaging lines, electronic assembly, CNC auxiliary axes, or indexing conveyors. You might notice that its low rotor inertia makes it easier to hit short cycle times without overshoot, which in many cases trims machine tact time and reduces settling.

One thing I appreciate is how easily the MPL-B330P-MJ72AA pairs with Kinetix 6000/5500/5700 drives and standard 2090 power/feedback cabling. Commissioning typically goes quickly—auto‑tuning on the drive locks in stable response, and the J72 feedback option gives reliable, high‑resolution position data for repeatable results. A packaging OEM told us their pick‑and‑place station “dropped from 120 ms to 90 ms settle time” after swapping to this B‑frame MPL, with no other mechanical changes.

Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Low‑inertia rotor – Designed for rapid starts/stops and short settling, ideal for indexing and pick‑and‑place axes.

- J72 high‑resolution feedback – Provides precise position/speed data to Kinetix drives for smooth motion and tight control.

- P winding (high‑speed capability) – Suits applications that typically benefit from higher base speed with ample torque in the working range.

- Robust environmental design – Standard industrial sealing; with the correct shaft seal and cabling, IP ratings support washdown‑adjacent environments in most cases.

- Kinetix ecosystem compatibility – Works with Kinetix 6000/6200/6500, 5500, and 5700 drives, easing standardization across machines.

- IEC metric square‑flange mounting – Straightforward replacement in existing MP‑Series motor footprints with keyed output shaft.

- Quiet, smooth operation – Optimized electromagnetic design reduces ripple for better surface finish and less vibration on precision mechanisms.

Technical Specifications

| Brand / Model | Allen‑Bradley MPL-B330P-MJ72AA (MP‑Series, Low‑Inertia) |

| HS Code | 8501.52 (AC multi‑phase motors >750 W and ≤75 kW) |

| Motor Type | Brushless AC servo, low‑inertia rotor, permanent magnet |

| Power Requirements | Supplied by compatible Kinetix servo drive; typically used on 230 V‑class or 400/460 V‑class bus systems depending on winding (P winding is commonly applied with higher‑voltage drives) |

| Feedback / Encoder | J72 high‑resolution encoder option, supports precise commutation and position feedback with Kinetix drives |

| Signal I/O Types | 3‑phase motor power leads, feedback interface, protective earth; brake leads if brake‑equipped (this AA configuration is typically without brake) |

| Communication Interfaces | Feedback to Kinetix drive via 2090-series cable sets (power and feedback), supported by Kinetix 6000/5500/5700 platforms |

| Operating Temperature | 0…40 °C ambient (non‑condensing), typical for MP‑Series |

| Ingress Protection | Standard industrial sealing; up to IP65 when used with proper shaft seal and mating connectors |

| Installation Method | IEC metric square‑flange mounting (B‑frame), keyed shaft; natural convection cooling |

| Dimensions & Weight | B‑frame low‑inertia form factor (MPL‑B330 stack). For exact outline and mass, match to the MPL‑B330 drawing for this option code. |

Related or Supporting Products

- Kinetix 6000 / 6200 / 6500 (2094) multi‑axis servo drives – Proven match for MP‑Series motors; great for multi‑axis machines.

- Kinetix 5500 (2198) and 5700 (2198) – Newer platforms with compact footprints and higher power density; commonly used with MPL and VP motors.

- Kinetix 350 (2097) single‑axis drive – Suits standalone axes when power sizing aligns.

- 2090-Series Cables – 2090 power and feedback cable sets (for example 2090-CPBM/CPWM families) to connect the MPL motor to the drive.

- Comparable motors – MPL-B330P-MJ74AA (alternate feedback), MPL-B330P-SJ72AA (alternate winding), or the newer VPL series (VP Low‑Inertia) when a more compact, energy‑efficient option is preferred.

Installation & Maintenance

- Mounting & cabinet environment: Rigidly mount to an IEC square‑flange interface with proper shaft alignment. Keep drive and motor cabling routed separately from high‑noise power lines inside a ventilated cabinet (per IEC/UL wiring practices).

- Ventilation: Allow natural convection around the motor body; avoid enclosing the motor without airflow. If near washdown areas, use the correct shaft seal and mating connectors to maintain ingress protection.

- Wiring & grounding: Use 2090‑series shielded power/feedback cables, bond shields at the drive end, and ensure a solid protective earth connection to minimize EMI and improve encoder signal integrity.

- Safety precautions: Lock out power, discharge DC bus on the drive, and verify zero energy before handling connectors. If a brake is present, control 24 VDC safely to prevent unintended motion.

- Routine maintenance: Inspect connectors and cable strain reliefs quarterly, check for shaft seal wear if installed, and clean accumulated dust to maintain thermal performance. Firmware updates are handled on the Kinetix drive; re‑run autotune after significant mechanical changes.

- Commissioning tip: From my experience, starting with a medium stiffness/low bandwidth autotune profile avoids hunting on light‑load axes; then increase bandwidth step‑by‑step to reach the desired response.

Quality & Certifications

- CE and UKCA conformity (typical for MP‑Series)

- cULus compliance for industrial control equipment

- RoHS compliant materials

- Manufactured under ISO 9001 quality systems

- Manufacturer’s standard warranty is typically 12 months; our supply warranty is 365 days as stated above

Reviews

There are no reviews yet.