Description

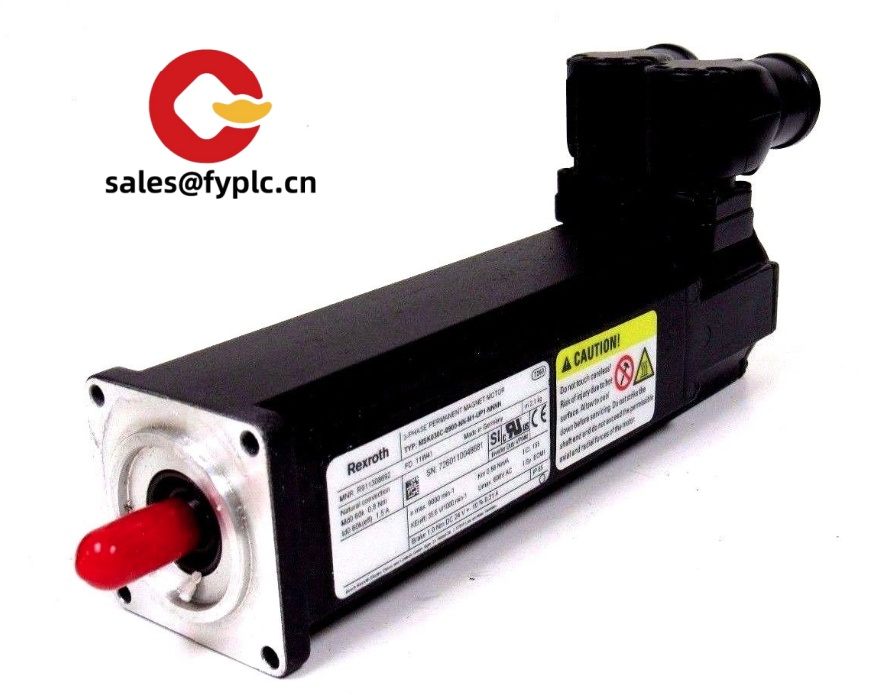

REXROTH MSK030C-0900-NN-S1-UP0-NNNN – Compact IndraDyn S Servo Motor for Precise, High‑Speed Axes

The REXROTH IndraDyn S MSK030C-0900-NN-S1-UP0-NNNN is a small-frame, high-dynamics synchronous servo motor designed for precise positioning and fast cycle duties. It fits tight spaces, responds quickly, and pairs naturally with IndraDrive controllers for smooth motion. You’ll typically see this size on pick‑and‑place stations, miniature gantries, labelers, optical stages, and compact delta robots where low inertia and repeatability matter more than raw torque.

One thing I appreciate is how quietly these MSK motors run when tuned right—jerk-limited profiles feel almost silky, which operators do notice.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Compact MSK 030 frame – The small footprint and “C” length make it easy to fit into dense machine layouts without compromising dynamics.

- High dynamic response – Low rotor inertia and optimized windings (0900 code) typically deliver fast acceleration/deceleration for short cycle tasks.

- Precise positioning – Integrated absolute feedback helps achieve tight repeatability when paired with IndraDrive (HCS01/HCS02, CSB/CMS controls).

- Robust design – IP65 housing concept with sealed shaft options supports dusty or splash-prone environments when installed correctly.

- Flexible connectors & cabling – Standard power/feedback connectors simplify routing, and Rexroth hybrid cable sets speed up commissioning.

- Broad application fit – From my experience, this size suits single‑axis feeders, test fixtures, and lightweight axes in electronics assembly.

- Variant coding benefits – The “S1/UP0” codes on this unit typically indicate a single‑turn absolute feedback and a standard keyed shaft with seal; confirm against the nameplate if you need an exact encoder interface.

Technical Specifications

| Item | Details |

|---|---|

| Brand / Model | REXROTH IndraDyn S – MSK030C-0900-NN-S1-UP0-NNNN |

| Motor Type | Synchronous servo motor, surface‑cooled (natural convection) |

| HS Code | 8501.51.00 (AC motors, output not exceeding 750 W; typical for this frame) |

| Power Requirements | Driven by Rexroth IndraDrive DC bus (typically ~320–560 VDC from 3‑phase 380–480 VAC drive input); brake supply 24 VDC if equipped |

| Dimensions & Weight | Frame size 030, length C; compact lightweight design. Detailed drawing and mass depend on variant and are available on request. |

| Operating Temperature | 0…+40 °C ambient for rated data (derating may apply above this range) |

| Protection / Insulation | IP65 (proper connector sealing), insulation class F (typical for MSK series) |

| Signal Input/Output | 3‑phase motor phases U/V/W; brake leads (24 VDC) if equipped; integrated absolute encoder feedback via dedicated connector |

| Feedback / Communication | Absolute encoder (single‑turn for S1 code in many cases); interface such as Hiperface/EnDat depending on exact sub‑variant; no fieldbus on motor |

| Installation Method | IEC‑style flange mounting; horizontal or vertical; connectors oriented per variant; standard keyed shaft/seal indicated by UP0 code in typical builds |

Note: Exact encoder type, shaft details, and torque/speed ratings are variant‑specific. We’ll verify against your nameplate or machine BOM to avoid surprises.

Related or Supporting Products

- REXROTH MSK030B / MSK040B/MSK040C – Similar motors with different stack lengths or higher torque ratings.

- REXROTH MS2N03 series – Newer generation servo motors with higher encoder resolution and improved thermal models; a common upgrade path.

- REXROTH MKE030 – Explosion‑proof variant for hazardous areas (if ATEX is required).

- IndraDrive HCS01 / HCS02 with CSB/CMS control sections – Recommended servo drives for seamless commissioning.

- Rexroth power and feedback cables (RKT/RKH) – Shielded cable sets sized for MSK03x motors; reduce EMC issues and speed up install.

Installation & Maintenance

- Mounting and cabinet: Use a rigid IEC flange and align the shaft carefully to avoid bearing load. Keep the drive in a ventilated cabinet (IEC 61439‑compliant) with proper cable routing and EMC grounding.

- Wiring: Use Rexroth‑approved shielded motor and encoder cables. Ground the shields at the drive side, and ensure connector seals are fully seated to maintain IP65.

- Environment: Avoid oil spray on the shaft seal; if unavoidable, select an appropriate seal material. Keep ambient within 0…40 °C for rated operation.

- Safety: Lock out power, discharge DC bus, and verify absence of voltage before handling. The brake (if present) is not a safety brake—use a mechanical safety device where required.

- Routine maintenance: Inspect connectors and cable strain relief every 6–12 months; clean fins to maintain convection cooling; check shaft seal for leaks; verify brake air‑gap; and update IndraDrive firmware as recommended.

Quick field note: A packaging OEM told us the MSK030C ran noticeably smoother on small rotary knives after we switched them to matched RKT/RKH cable sets and re‑tuned velocity feedforward—seems to be the combo that eliminates their micro‑vibrations.

Quality & Certifications

- CE conformity (Machinery/EMC/Low Voltage) – typical for IndraDyn S motors

- UL/cUL recognition – widely used in North American panels

- RoHS compliance – materials and finishes per current directives

- Manufacturer’s quality system: ISO 9001

- Our warranty: 365 days from delivery

Reviews

There are no reviews yet.