Description

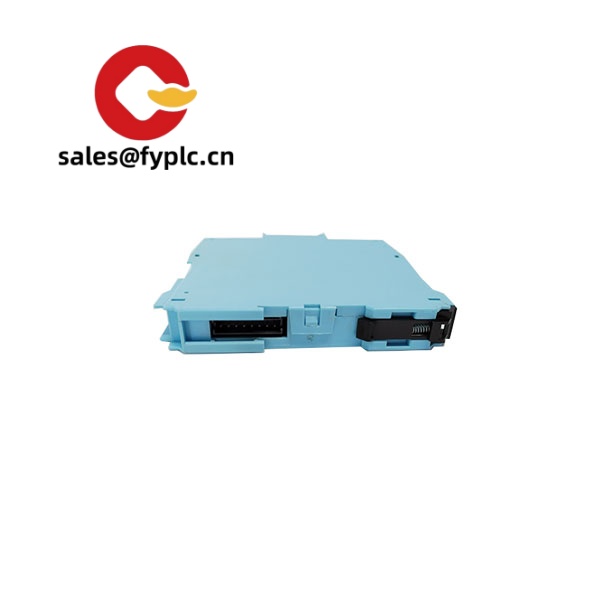

MTL MTL5549 – Intrinsically Safe 4–20 mA Isolator for Hazardous-Area Transmitters

The MTL5549 sits in the proven MTL5500 series and is typically used as a repeater power supply for 2‑wire transmitters in hazardous areas. From my experience, it’s the kind of “fit-and-forget” analog isolator you drop into a marshaling cabinet when you need clean 4–20 mA with galvanic isolation and HART pass-through, without eating up panel space. You might notice that it’s slim, DIN-rail friendly, and plays nicely with existing DCS/PLC analog input cards—exactly what most brownfield upgrades need.

Order Placement Process & Guarantees

-

- – Warranty: 365 days from shipment

-

- – Delivery: 1 week if in stock; no more than 1 month latest

-

- – Payment: 50% advance payment; full payment prior to delivery

- – Express options: FedEx, UPS, DHL

Key Features

- Repeater power supply for 2‑wire transmitters – Powers a hazardous‑area transmitter and reproduces a clean 4–20 mA signal on the safe side.

- Galvanic isolation – Breaks ground loops and improves noise immunity between field and control system, which in many cases stabilizes readings.

- HART transparency – Typically supports HART pass‑through so you can configure and diagnose devices without extra wiring.

- Slim DIN‑rail footprint – Compact module width helps increase cabinet density; easy to slot alongside other MTL5500 units.

- Safe- and hazardous‑area segregation – Clear terminals and labeling reduce wiring mistakes during hot-cutover work.

- System-friendly power – Runs from a standard 24 VDC cabinet supply, either via the backplane or terminals.

Typical Use Cases

- Loop-isolated AI channels for pressure, flow, or level transmitters located in Zone 1/Division 1 areas.

- Brownfield upgrades where you need HART diagnostics without changing existing AI cards.

- Long cable runs where ground potential differences and noise seem to be causing drift or spikes.

Technical Specifications

| Brand / Model | MTL / MTL5549 (MTL5500 Series) |

| HS Code | 8537.10 (Control panels/units for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal (typically 20–35 VDC via backplane or terminals) |

| Signal I/O Types | Hazardous‑area 2‑wire transmitter input; safe‑area 4–20 mA output, HART transparent (typical) |

| Operating Temperature | –20 to +60 °C (–4 to +140 °F), typical for the series |

| Dimensions & Weight | Slim DIN module; approx. 12.5 mm W × 119 mm H × 115 mm D; ~150 g |

| Communication Interfaces | None (analog pass‑through); HART signals typically pass to the host |

| Installation Method | DIN‑rail mounting with MTL5500 backplane or direct DIN-rail terminals |

Related or Supporting Products

- MTL5546 – Repeater power supply with similar function; in many cases chosen where channel density or specific drive levels are required.

- MTL5541 – Solenoid/alarm driver; use this when you need to drive coils or audible/visual alarms rather than power a transmitter loop.

- MTL5511 / MTL5513 – Switch/NAMUR proximity detector interfaces for discrete inputs from hazardous areas.

- MTL4549 – 4500‑series counterpart for sites standardized on the MTL4500 footprint.

- MTL4850 HART Multiplexer – Pulls HART diagnostics from multiple loops without disturbing the analog measurement.

Installation & Maintenance

One thing I appreciate is how straightforward these are to commission. Still, a few habits save time and rework:

- Cabinet & mounting – Install on a grounded DIN rail inside a ventilated cabinet. Keep IS field wiring segregated from non‑IS wiring with clear trunking separation.

- Power & earthing – Use a clean 24 VDC source. Bond the backplane/rail earth as recommended to maintain isolation integrity.

- Wiring – Hazardous‑area connections to the field transmitter; safe‑area output to the DCS/PLC AI card. Maintain polarity and loop continuity; leave room for HART test clips if you routinely connect handhelds.

- Environmental – Operate within the stated temperature range; avoid high‑vibration spots or heat sources that can accelerate drift.

- Routine checks – Verify 4–20 mA span during instrument calibrations, clean terminal areas to prevent ingress, and document any device label revisions. Firmware updates aren’t typically applicable for this type of analog isolator.

- Safety – Confirm hazardous‑area classification and entity parameters match your transmitter. Never hot‑swap in a live hazardous environment.

Quality & Certifications

- Manufacturer compliance typically includes CE and RoHS for industrial control equipment.

- Intrinsic safety approvals (e.g., ATEX/IECEx/FM/CSA) are associated with the MTL5500 series; please verify exact markings on your MTL5549 unit and local approvals required by your site.

- Warranty: 12 months from shipment as stated above.

Field note from a recent turnaround: swapping older barriers for MTL5549 units tightened up loop stability on a few noisy transmitters, and HART diagnostics came through reliably without adding any external modems. That’s usually the kind of low‑risk upgrade operations teams like—clean, quick, and traceable.

Reviews

There are no reviews yet.