Description

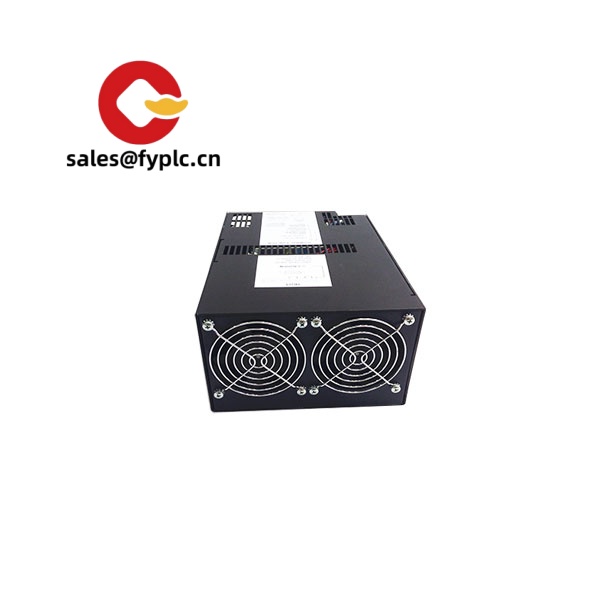

Sanyo Denki P30B04010PCKST – Pulse/Analog AC Servo Drive for Precise Motion Control

The Sanyo Denki P30B04010PCKST is a SANMOTION P-series AC servo amplifier designed for pulse-train and analog command control. It’s typically used in pick-and-place gantries, compact packaging machines, labeling stations, and light-duty indexing applications where responsive speed/position loops and reliable STO safety are expected. One thing I appreciate is how straightforward it is to integrate with PLCs using standard pulse I/O, while still giving you the analog path when torque or speed control is preferred.

Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express shipping: FedEx, UPS, DHL

Key Features

- Pulse/Analog command flexibility – Supports common pulse-train formats for position control and ±10 V analog input for speed/torque loops, making PLC integration simple.

- STO (Safety Torque Off) – Typically provided on this suffix to meet machine safety concepts without adding external contactors for basic safe stop.

- Auto-tuning with vibration suppression – From my experience, the P-series does a solid job damping resonances on lighter frames and belt drives, reducing settling time in many cases.

- Compact 200 V-class frame – Fits tight panels while delivering stable current control for small to mid-range servomotors.

- Standard 24 V I/O – Ready-to-use enable, alarm, limit, and ready signals for quick PLC handshaking.

- Encoder feedback support – Works with matched Sanyo Denki servo motors (incremental/absolute types depending on motor pairing).

- Regeneration handling – Compatible with external regenerative resistors where required for fast decel moves.

Technical Specifications

| Brand / Model | Sanyo Denki SANMOTION P – P30B04010PCKST (AC servo amplifier) |

| HS Code | 8504.40 (Static converters, servo drive category) |

| Power Requirements | AC 200–230 V class (typical for P30B series) |

| Signal Input/Output | Pulse-train inputs (position), ±10 V analog command (speed/torque), 24 V digital I/O, motor encoder feedback |

| Communication Interfaces | Drive-side setup via vendor tool/port; field I/O via pulse/analog and 24 V signals (series-standard) |

| Operating Temperature | 0–55 °C (typical panel environment) |

| Installation Method | Panel mount inside control cabinet; vertical orientation with clearance for airflow |

| Dimensions & Weight | Compact 200 V-class frame (typically under 2 kg; exact outline per capacity) |

Related and Supporting Products

- Sanyo Denki P30B05010PCKST – Similar interface with higher capacity rating; a direct step-up when extra torque is needed.

- Sanyo Denki P30B04010PCEST – Same capacity class with different interface option set (suffix varies I/O/comms features).

- SANMOTION R servo motors (matched) – Pair with compatible Sanyo Denki AC servomotors for best autotuning and encoder feedback support.

- Regenerative resistor unit – Recommended for fast deceleration cycles to protect the DC bus during frequent stops.

- Motor/encoder cables (factory assemblies) – Shielded power and feedback cables sized for the drive-motor pairing; helps reduce EMI and setup time.

- EMI filter and line reactor (as needed) – Improves EMC performance and line quality in noise-sensitive plants.

Installation & Maintenance

- Cabinet & mounting – Install vertically on a metal backplate in an IP20 or better control cabinet. Keep top/bottom clearance (typically ≥100 mm) for convection and any forced-air cooling.

- Power & grounding – Use appropriate 200–230 V supply with protective earth. From my experience, a clean ground and proper shield termination eliminate 90% of “nuisance” encoder alarms.

- Wiring – Separate motor power cables from feedback and I/O wiring. Use shielded twisted pairs for pulse/encoder lines.

- Regeneration – For high-inertia loads or sharp decel profiles, size and connect an external regenerative resistor per the drive’s calculation guide.

- Safety – Wire STO channels according to the manufacturer’s safety diagram. Verify stop performance during commissioning.

- Routine maintenance – Quarterly dust cleaning, connector re-seating checks, and a quick parameter backup. Firmware updates, when available, should be scheduled during planned downtime.

- Tuning – Start with auto-tuning, then add notch filters for mechanical resonances. You might notice that even minor stiffness adjustments can shorten settle times on lightweight axes.

Quality & Certifications

- CE and RoHS compliant (typical for SANMOTION P-series drives)

- UL/cUL recognition on most regional variants

- Manufacturer warranty practices apply; we support a 365-day warranty on supply

Quick customer note from a recent retrofit: swapping to a P30B pulse drive shortened their indexing cycle by about 8–12% after basic tuning and adding a small regen unit. It seems to be a sweet spot when you want responsive motion without moving the whole line to an industrial fieldbus.

Reviews

There are no reviews yet.