Description

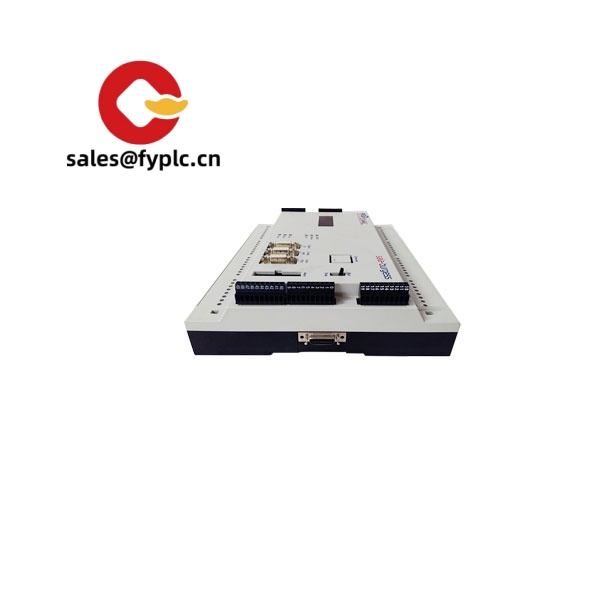

Honeywell Saia PCD2.M48X – Modular PLC CPU for reliable building and industrial control

The Honeywell Saia PCD2.M48X is a mid‑range PLC CPU base that typically serves as the “control core” in HVAC plants, utilities, and small to medium production lines. One thing I appreciate is how it balances flexibility and simplicity: you get a robust CPU, local modular I/O slots, and open communications like Ethernet and serial ports—without the overhead of a complex rack system. In many cases, it’s chosen for air handling units, chilled water plants, and process skids where you need dependable logic, web-enabled diagnostics (on supported variants), and straightforward expansion.

Order Placement Process & Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Modular CPU base for PCD2 system – supports local plug‑in I/O cards, so you size the controller to the job instead of overbuying.

- Open communications – typically includes 10/100 Ethernet and multiple serial ports for Modbus TCP/RTU, BACnet/IP (on supported firmware), and peer‑to‑peer links.

- Web & diagnostics (variant‑dependent) – many PCD2.M48x units provide embedded web functions for dashboards, parameter tweaks, and logs.

- Fanless, 24 VDC operation – quiet and dependable in control panels; ideal for mechanical rooms and electrical cabinets.

- Scalable I/O – mix digital, analog, and specialized I/O using PCD2.W series modules; add remote I/O via Ethernet/serial if needed.

- Engineering ecosystem – supports the Saia PG5 toolchain with proven libraries for HVAC and utilities; easy to maintain across sites.

- Industrial temperature range – designed for typical control panel environments; solid EMC immunity with proper grounding and wiring practice.

Technical Specifications

| Brand / Model | Honeywell Saia PCD2.M48X (family, e.g., PCD2.M480 series) |

| HS Code | 8537.10 (Programmable logic controllers) |

| Power Requirements | 24 VDC (typ. 18…32 VDC), consumption ~8–12 W depending on I/O and communications activity |

| Dimensions & Weight | Approx. 175 × 130 × 65 mm; ~0.6 kg (CPU base only; varies by sub‑variant and installed I/O) |

| Operating Temperature | 0…55 °C; 5–95% RH non‑condensing (typical for PCD2 controllers) |

| Signal Input/Output Types | Modular via PCD2.W series: 24 VDC digital inputs, transistor/relay outputs, 0–10 V / 4–20 mA analog I/O, thermistor/RTD (with appropriate modules), high‑speed counters |

| Communication Interfaces | 1× 10/100Base‑T Ethernet (typical), 2× serial (RS‑232/RS‑485 configurable), optional fieldbus via add‑on modules (e.g., BACnet MS/TP, LonWorks, PROFIBUS DP) depending on variant and firmware |

| Installation Method | 35 mm DIN‑rail mounting in control cabinet (EN 60715), front wiring with removable terminal blocks |

Related & Supporting Products

- PCD2.M480 / PCD2.M487 – Closely related CPU variants; M487 typically adds more memory or comms depending on firmware package.

- PCD3.Mxxx – Higher‑performance successor platform if you need more CPU power, larger memory, or extended networking.

- PCD1.M2xx – Compact alternative for smaller points counts with built‑in I/O.

- PCD2.W series I/O – Examples: PCD2.W1xx (digital inputs), PCD2.W2xx (digital outputs), PCD2.W3xx (analog I/O) to tailor channels and signal types.

- PCD7.F communication modules – Options for BACnet MS/TP, LonWorks, PROFIBUS, and other fieldbuses where required.

- PCD7.R memory/media – Program and data backup modules; handy for quick controller swap‑outs.

- 24 VDC panel power supplies – e.g., PCD2.C100 or equivalent industrial 24 VDC PSU, sized to total load including I/O.

Installation & Maintenance

- Panel environment – Mount on 35 mm DIN rail inside a metal cabinet with proper bonding to PE. Provide ventilation clearance (typically ≥50 mm above/below) and avoid heat sources.

- Power & wiring – Use a regulated 24 VDC supply with adequate headroom. Separate power, analog, and communication wiring; shield and ground RS‑485 as per EMC best practices.

- Network setup – Assign fixed IPs or use DHCP reservations for controllers and HMIs. For BACnet/IP or Modbus TCP, keep a simple VLAN structure to reduce broadcast noise.

- Firmware & backups – Keep firmware aligned across sites; store the latest program and configuration on a PCD7.R module or secure server for fast recovery.

- Routine care – Dust the cabinet filters, check terminal tightness seasonally, and review diagnostic logs. From my experience, a quick comms health check (ping/latency, error counts) prevents surprise downtime.

- Safety – De‑energize before service, verify isolation on field circuits, and follow local electrical codes. Label I/O and keep a printed I/O map in the cabinet door—small step, big payoff.

You might notice that commissioning goes faster on mixed‑protocol jobs. A contractor told us they used a PCD2.M48x to tie together BACnet/IP chillers and Modbus VFDs on a hospital retrofit; the built‑in Ethernet and serial ports saved them an extra gateway and several hours onsite.

Quality & Certifications

- Certifications: CE, RoHS; many PCD2 controllers also carry UL/cUL listings for control equipment (varies by exact sub‑model).

- Manufacturing quality: Produced under ISO 9001 quality systems.

- Warranty: 365 days from delivery as stated above.

Note: PCD2.M48X denotes a family with sub‑variants (e.g., firmware and comms options). If you share your exact code (such as PCD2.M480), I can match the precise Ethernet/serial count, memory size, and supported protocols so the spec aligns 1‑to‑1 with your application.

Reviews

There are no reviews yet.