Description

NI PCI-8517 – Single-Wire CAN (SW-CAN) Interface Card for Automotive Networks

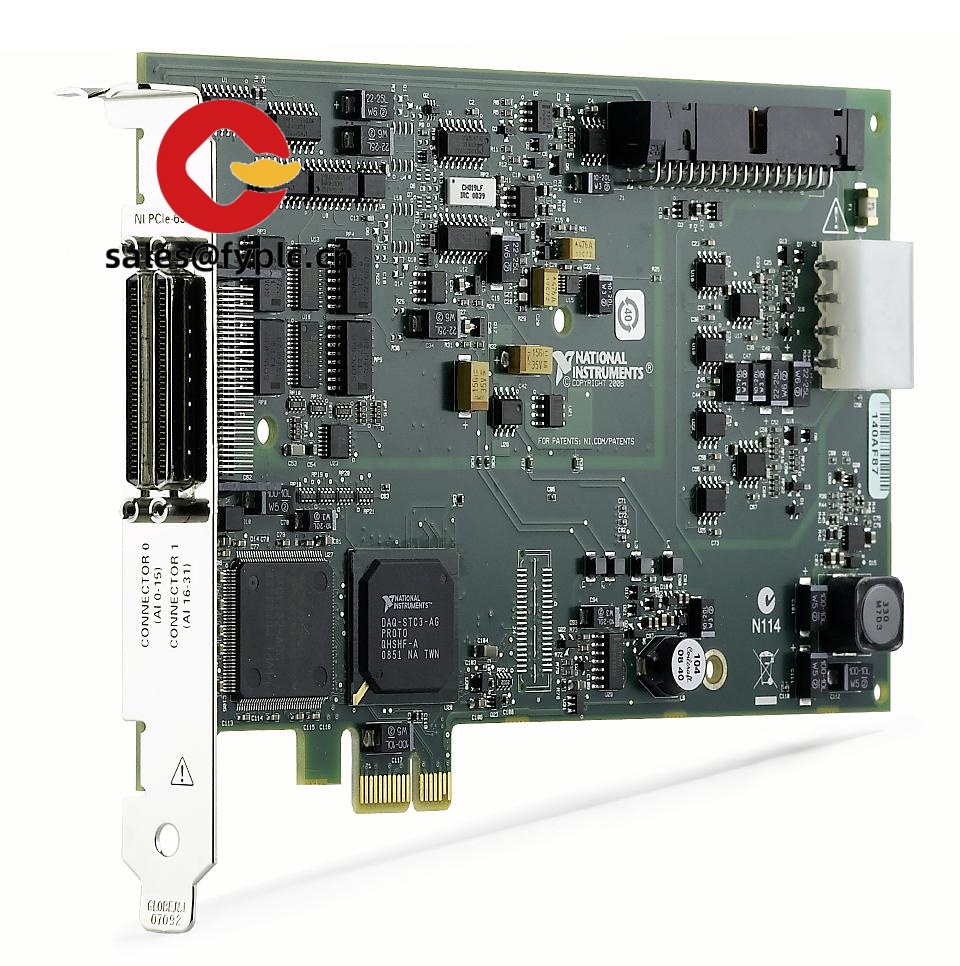

The NI (National Instruments) PCI-8517 is a hardware-accelerated NI-XNET interface that brings Single-Wire CAN (SW-CAN, SAE J2411/GMW3089, often known as GMLAN) into a standard desktop or industrial PC. From my experience, teams reach for the PCI-8517 when they need dependable body electronics testing, gateway simulation, or in-vehicle network diagnostics without re-architecting an existing PCI-based test bench. You might notice that it behaves like other NI-XNET interfaces you already use—same API, same databases, just optimized for SW-CAN’s wake/sleep behavior and bus characteristics.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 1-port Single-Wire CAN (SAE J2411/GMW3089) – Purpose-built for automotive body networks, BCMs, door modules, and infotainment backbones.

- NI-XNET hardware acceleration – High-performance signal/Frame I/O, optimized queues, and low CPU overhead for logging, restbus simulation, and real-time test.

- Bus wake and sleep handling – Supports typical SW-CAN wake-up/sleep states used in GMLAN-style architectures.

- DB-9 connectivity – Simple wiring to existing harnesses or breakout boxes; easy to integrate with standard CAN accessories.

- Database-centric workflows – Use .dbc files for quick mapping of frames to signals; typically shortens setup time during ECU bring-up.

- Robust automotive transceiver – In many cases offers short-circuit and fault protection suited to 12 V vehicle environments.

- Tight LabVIEW and VeriStand integration – One thing I appreciate is how quickly you can pivot from monitoring to simulation without changing hardware.

- Deterministic timestamping – High-resolution time tags help with event correlation across multi-bus test stands.

Typical Use Cases

- ECU validation for body controllers, door modules, HVAC units, and infotainment gateways

- SW-CAN network logging and fault injection during vehicle teardown studies

- Restbus simulation to replace unavailable ECUs during staged integration

- Aftermarket/telematics device evaluation on GMLAN-style single-wire networks

Technical Specifications

| Brand / Model | National Instruments PCI-8517 |

| HS Code | 8517.62 (Data communication apparatus) |

| Power Requirements | Powered from PCI bus (3.3 V/5 V); no external supply required |

| Dimensions & Weight | Standard PCI short card; approx. 168 mm (L) × 107 mm (H); ~180 g |

| Operating Temperature | 0 °C to 55 °C (typical NI PCI card rating) |

| Signal Input/Output Types | 1 × Single-Wire CAN (SAE J2411/GMW3089), DB‑9 connector; supports bus wake/sleep |

| Communication Interfaces | 32‑bit PCI (33 MHz); NI‑XNET driver API for Windows; supports LabVIEW, VeriStand, and C/C++ |

| Installation Method | Internal PCI plug‑in card; full‑height bracket; connects to harness via DB‑9 |

Field note: A powertrain test engineer told us the PCI‑8517 cut their SW‑CAN logging gaps to zero during long endurance runs—mostly thanks to NI‑XNET’s streaming performance and lean CPU usage on older bench PCs.

Related or Supporting Products

- NI PCI-8516 (Low-Speed/Fault-Tolerant CAN) – For LS/FT CAN buses when SW-CAN isn’t required.

- NI PCI-8513 (High-Speed CAN) – For ISO 11898 high-speed CAN networks; ideal for powertrain and chassis domains.

- NI PCI-8512 (LIN) – LIN master/slave interface; pairs well for mixed CAN/LIN body electronics testing.

- NI CAN DB‑9 to bare-wire cable and DB‑9 breakout accessories – Simplifies harnessing, termination, and quick rework during debug.

Installation & Maintenance

- PC/chassis: Full‑height PCI slot with adequate airflow; avoid adjacent heat sources. Keep intake filters clean in industrial enclosures.

- Cabinet standards: For rack PCs, follow IEC/EN 60297 practices; ensure grounding continuity to reduce common‑mode noise.

- Ventilation: Maintain unobstructed airflow; typical clearance 25–50 mm around the card’s region within the chassis.

- Wiring: Use automotive‑grade harnessing to DB‑9. Observe SW‑CAN biasing/termination per SAE J2411/GMW3089; in most cases you should not add standard 120 Ω CAN terminations (SW‑CAN uses a different topology).

- Power domains: Reference grounds properly to the DUT. Avoid tying vehicle battery lines directly to the PC ground without review.

- Safety: ESD protection when handling the card; connect/disconnect to a de‑energized harness whenever possible.

- Routine maintenance: Periodic connector inspection/cleaning, verify harness strain relief, and update NI‑XNET drivers/firmware during scheduled downtime.

- Software notes: Keep .dbc files under version control; typically reduces mismatch errors during iterative ECU updates.

Quality & Certifications

- Certifications: CE, RoHS; FCC EMC compliance for IT equipment (typical for NI PCI interfaces)

- Manufacturer’s warranty: Typically 1 year from NI

- Our warranty coverage: 365 days from shipment

- Traceability: Lot/serial tracking available upon request

Reviews

There are no reviews yet.