Description

ABB PM876 Processor Module – High‑performance CPU for 800xA/AC 800M control

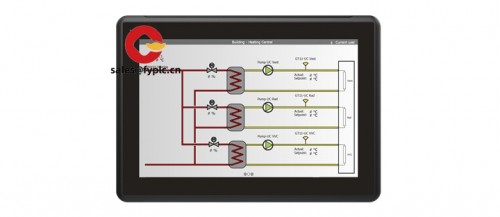

The ABB PM876 is a high‑performance processor module designed for ABB’s AC 800M family, typically used under the 800xA system. From my experience, the PM87x series is picked when plants need fast scan times, stable redundancy, and easy expansion via CEX‑bus communication interfaces and S800 I/O. You might notice that it slots into existing AC 800M bases without fuss, which makes upgrades and phased migrations less disruptive.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Performance for large DCS tasks: Built for complex control strategies and faster cycle times in 800xA environments.

- Redundancy support: Supports AC 800M controller redundancy with synchronization modules (commonly SM8xx series) for high availability.

- Flexible networking: Ethernet-based controller/plant network connectivity; expansion via CEX‑bus for field protocols.

- S800 I/O integration: No onboard I/O; connects to remote S800 I/O over ModuleBus for scalable system design.

- Engineering with Control Builder M: Compatible with ABB Control Builder for configuration, diagnostics, and firmware handling.

- Serviceability: Hot‑swappable module design in most cabinets; firmware and backups can be handled during scheduled windows to reduce downtime.

- Industrial temperature range: Typically suitable for control cabinets at standard plant ambient with adequate ventilation.

Technical Specifications

| Brand / Model | ABB PM876 |

| Product Type | Processor Module (CPU) for AC 800M / 800xA |

| HS Code | 8537.10 (control panels/PLCs, ≤1000 V; commonly used classification) |

| Power Requirements | 24 V DC nominal (typical AC 800M CPU supply) |

| Operating Temperature | 0 to +55 °C typical (cabinet installation with ventilation) |

| Signal I/O Types | No onboard discrete/analog I/O; uses S800 I/O via ModuleBus |

| Communication Interfaces | Ethernet (controller/plant network); expansion via CEX‑bus modules (e.g., PROFIBUS, PROFINET) |

| Installation Method | DIN‑rail mounting on AC 800M base; front‑access service ports |

| Dimensions & Weight | Standard AC 800M single‑module form factor; approx. 0.5–0.7 kg |

Related or Supporting Products

- ABB PM865 / PM866 / PM867 / PM891 – Alternative AC 800M CPUs. PM891 is the current high‑end option with faster processing and larger memory; PM865/PM866 are proven mid/high‑range choices.

- ABB SM812 (Synchronization Module) – For CPU redundancy pairing. In many cases, plants keep a spare on hand for quick swap.

- ABB CI854A/B (PROFIBUS), CI871 (PROFINET), CI853 (ModuleBus), CI869 (IEC 61850) – Common CEX‑bus communication interfaces depending on field network strategy.

- S800 I/O (e.g., DI810, DO810, AI810, AO810) – Modular remote I/O platform typically used with AC 800M.

- Industrial Ethernet switches – Managed, DIN‑rail switches with redundant power input; helpful for ring topologies and controller redundancy.

Installation & Maintenance

- Cabinet & environment: Install in an IEC‑rated enclosure with adequate ventilation. Keep ambient within 0…55 °C and 5–95% RH non‑condensing. Allow front clearance for cabling and service.

- Power & grounding: Use a clean 24 V DC supply with proper grounding and surge protection. From my experience, dedicating a PSU channel for the CPU reduces nuisance drops during motor starts.

- Networking: Use industrial Ethernet (Cat5e/6) and follow ABB’s topology rules for redundancy. Label CEX‑bus modules clearly to simplify maintenance.

- Redundancy setup: If deploying redundant CPUs, install the synchronization module, match firmware revisions, and verify switchover times during FAT/SAT.

- Firmware & backups: Keep controller firmware aligned with your 800xA/Control Builder version. Schedule backups after any logic or hardware change; store images offsite.

- Routine care: Annual cabinet cleaning (ESD‑safe), connector reseat checks, and periodic RTC/battery checks where applicable. You might notice that a simple spring‑clean prevents intermittent comm faults.

- EMC practices: Separate power and signal wiring, use shield terminations correctly, and maintain cable bend radii to protect the CEX‑bus and Ethernet links.

Field feedback: one automotive user reported that migrating to a PM87x CPU cut their scan time by roughly 30% while keeping the existing S800 I/O. The win was mainly in faster engineering downloads and smoother redundancy switchover.

Quality & Certifications

- Certifications: CE, UL, RoHS compliance; manufactured under ISO 9001 quality management

- Manufacturer warranty: Typically per ABB policy for new units

- Our guarantee: 365‑day warranty as stated above; genuine, test‑verified before shipment

Reviews

There are no reviews yet.