Description

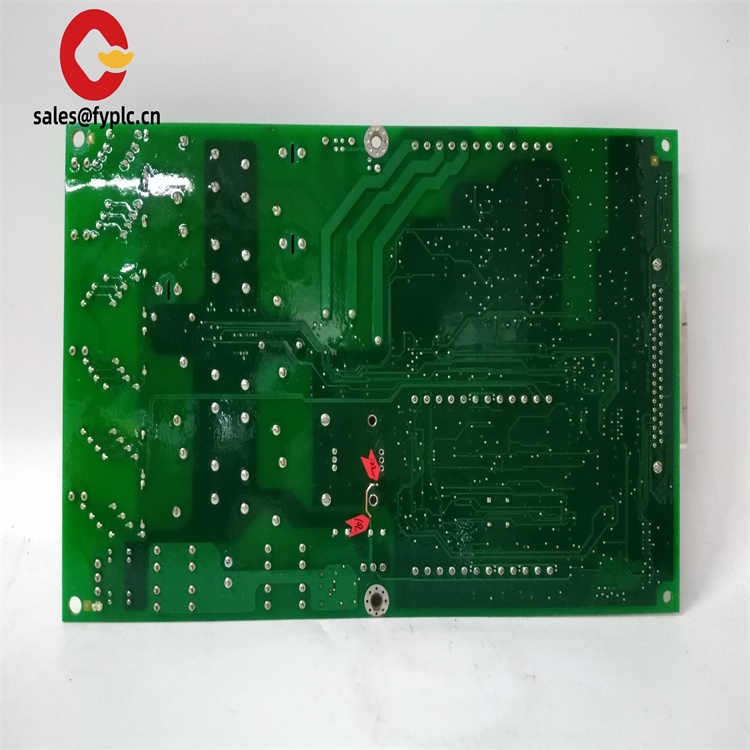

GE IS200AEADH4A | 109W3660P001 Gas Turbine Card Input/Output Module

IS200AEADH4A

The GE IS200AEADH4A 109W3660P001 is a high – performance analog input module designed for mission – critical industrial control applications3. It is mainly used in the monitoring and control of industrial automation systems, such as power plants, oil and gas fields, and chemical plants6. It plays a key role in turbine monitoring, power generation optimization, and process control, helping to improve the reliability and efficiency of the entire industrial control system.

| Label |

Specification |

| Model Number |

IS200AEADH4A 109W3660P001 |

| Brand |

GE Industrial Systems |

| Type |

Analog Input Module |

| Input Voltage |

+5VDC ±5%, 1.2A max |

| Operating Temp |

-40°C to +70°C |

| Communication Method |

Backplane bus (such as VME or PCI) |

| Mounting |

Insert into the designated slot of the Mark VI rack |

| Weight |

e.g., 0.5 kg |

| Certifications |

Complies with SIL2/SIL3 functional safety level |

| Dimensions |

100mm x 50mm x 20mm |

| IP Rating |

Not specified |

| Protocols Supported |

N/A |

The

GE IS200AEADH4A 109W3660P001 stands out with its advanced features

3. It has 16 isolated channels, supporting input types such as TC, RTD, and mV (±50mV to ±1000mV) with a 16 – bit resolution and an accuracy of ±0.1% of FSR @ 25°C

3. The module offers 1500V RMS channel – to – channel isolation, ensuring reliable data acquisition in harsh electromagnetic environments

3. It also features automatic sensor diagnostics, configurable input ranges, and advanced signal conditioning capabilities, including proprietary noise filtering algorithms and 24 – bit digital filtering

3.

IS200AEADH4A

In industrial applications, the GE IS200AEADH4A 109W3660P001 is widely used in power plants, oil and gas fields, and chemical processing plants6. In power plants, it monitors the temperature and pressure of steam turbines, optimizes power generation, and integrates with the DCS system for plant – wide energy efficiency management16. In oil and gas fields, it is used for the control of pipelines, refineries, and offshore platforms6. In chemical processing plants, it monitors and controls chemical reactors, distillation columns, and other critical processes6.

Reviews

There are no reviews yet.