Description

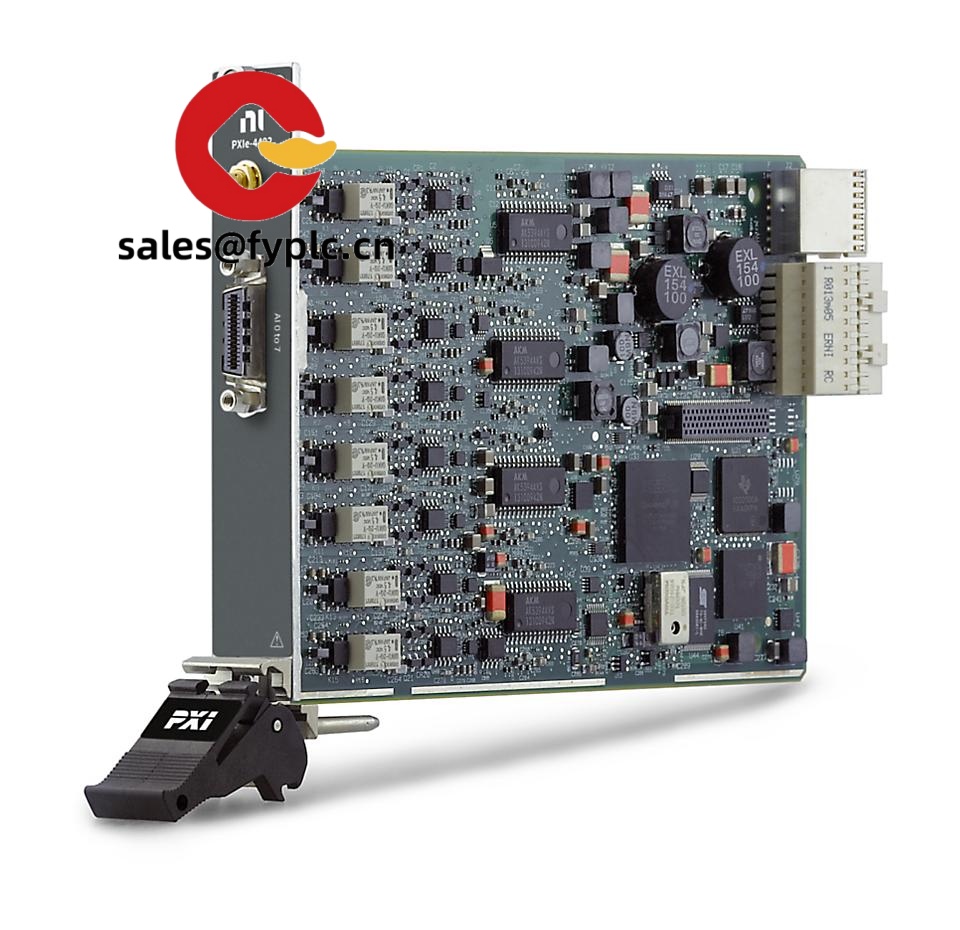

NI PXI-8119 Embedded Controller for PXI Test Systems – High-Performance System Slot CPU for Automated Test Racks

The NI PXI-8119 is a high-performance embedded controller designed to run an entire PXI test system from the system slot. From my experience, this model suits engineers who need deterministic, high-throughput control without the complexity of an external PC—especially in production test, hardware-in-the-loop, and mixed-signal validation benches. You might notice that it boots fast, handles multi-instrument synchronization cleanly over the PXI backplane, and typically keeps system wiring tidy thanks to its rich front-panel I/O.

Our Order Placement Process & Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- System-slot embedded control – Runs the PXI chassis as a standalone ATE platform, no external host required.

- Multi-core Intel architecture – Well-suited for parallel test, data logging, and real-time sequencing; performance typically scales well with LabVIEW, TestStand, and NI drivers.

- PXI backplane timing and triggers – Native access to PXI triggers and star trigger lines simplifies precise synchronization across modules.

- Rich front-panel I/O – Commonly includes Gigabit Ethernet, USB, serial, and video ports for easy integration with instruments, DUT fixtures, and factory networks.

- Rugged 3U PXI form factor – Designed for continuous operation in industrial test racks with stable thermal behavior in most cases.

- Serviceability – Field-replaceable storage (varies by configuration) and straightforward OS imaging make maintenance predictable.

- Software ecosystem – Optimized for NI drivers (NI-DAQmx, NI-SCOPE, NI-DCPower, etc.) and test frameworks like TestStand.

Technical Specifications

| Brand / Model | National Instruments PXI-8119 |

| HS Code | 8471.50 (Processing units for automatic data processing machines) |

| Power Requirements | Powered from PXI chassis backplane; no external PSU required (consumption varies by configuration) |

| Form Factor / Dimensions | 3U PXI system-slot embedded controller; fits standard PXI 3U chassis per PXI specification |

| Operating Temperature | Typically 0 °C to 55 °C (actual limits depend on specific unit and configuration) |

| Signal I/O Types | Front panel: USB, Gigabit Ethernet, video output (VGA/DVI or similar), RS‑232 (varies by revision); PXI backplane triggers and PCI signaling |

| Communication Interfaces | PXI backplane, Ethernet, USB, serial; display output for local HMI/monitor |

| Installation Method | Front-insert into system slot of PXI chassis; secure with captive screws; OS imaging via NI tools |

Related or Supporting Products

- NI PXI-8115 – A capable PXI system controller with slightly lower CPU performance; good for cost-sensitive benches.

- NI PXIe-8135 – PXI Express system controller with higher bandwidth to PXIe modules; ideal when you need faster data movement.

- NI PXIe-8880 – High-end multi-core PXIe controller for compute-heavy RF and mixed-signal test (a modern upgrade path).

- PXI Chassis (e.g., NI PXI-1042, PXI-1033) – Compatible 3U PXI chassis options; choose slot count and cooling to match your test set.

- Storage & Memory Upgrades – 2.5″ SATA SSDs and DDR3/DDR3L memory (capacity depends on controller revision).

- Software – NI LabVIEW, TestStand, and NI driver suites (NI‑DAQmx, NI‑RFSA, NI‑DCPower) for rapid deployment.

Installation & Maintenance

- Cabinet & chassis – Use a PXI 3U chassis with adequate airflow; maintain clearance at front and rear for cooling. In many cases, a filtered intake reduces dust buildup.

- Ventilation – Keep ambient temperature within the rated range; avoid recirculating hot air from power supplies or DUT loads directly into the controller’s intake.

- Wiring – Route Ethernet/USB/serial away from high-current lines to reduce noise. Secure cables to prevent stress on front-panel connectors.

- Grounding – Ensure chassis ground bonding to rack earth. This typically improves measurement stability and ESD robustness.

- OS & firmware – Apply NI-recommended BIOS and driver updates during scheduled maintenance windows. Create a known-good disk image before major changes.

- Routine checks – Quarterly dust cleaning with dry air, verify fan health and temperature logs, and confirm trigger line integrity during system self-tests.

- Calibration workflow – The controller itself doesn’t require calibration, but coordinating calibration intervals for PXI measurement modules via the same downtime saves effort.

Quality & Certifications

- CE and RoHS compliant (typical for NI embedded controllers)

- Designed and manufactured under ISO 9001 quality systems

- Safety approvals such as cULus are commonly available for NI PXI controllers

- Manufacturer’s warranty policies apply; our coverage is 365 days from delivery

One thing I appreciate is how the PXI-8119 balances compute performance with stable I/O and easy service. If your workload leans heavier on streaming and data crunching, a PXIe controller like PXIe‑8135 or PXIe‑8880 may be a better match; but for classic PXI systems, the PXI‑8119 remains a solid, dependable choice.

Reviews

There are no reviews yet.