Description

NI PXI-8252 – PXI IEEE 1394b (FireWire 800) Interface for Machine Vision Cameras

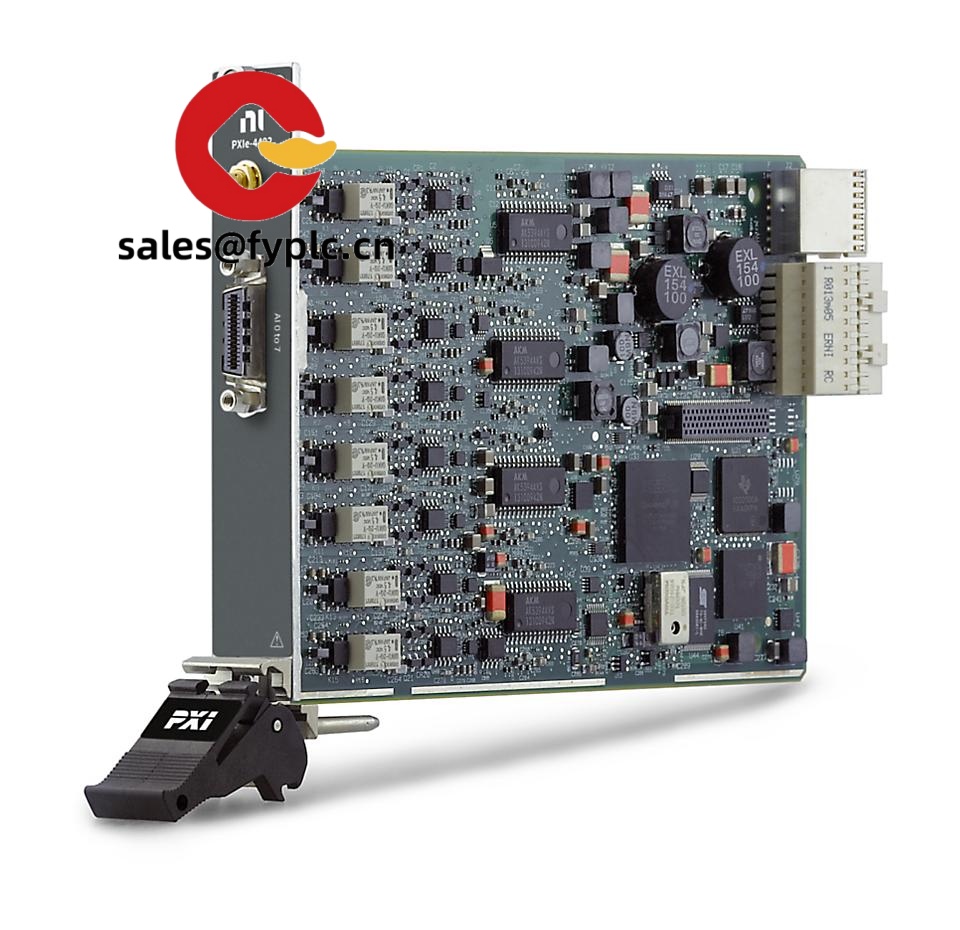

The NI PXI-8252 is a 3U PXI interface module for IEEE 1394b (FireWire 800) cameras, typically used in vision inspection, lab automation, and production test lines where legacy or established 1394 imaging chains still run reliably. It gives you two front-panel 9‑pin IEEE 1394b ports and works with NI-IMAQdx, so you can bring DCAM/IIDC-compliant cameras straight into LabVIEW or your preferred NI software stack without extra middleware. One thing I appreciate is how simple it is to keep older FireWire vision assets in service while modernizing the rest of the PXI system around them.

Typical use cases include continuous web inspection with 1394b line-scan cameras, optical alignment stations that rely on deterministic triggering, and R&D benches where repeatable camera behavior matters more than jumping standards. You might notice that the PXI-8252 keeps cabling tidy inside the chassis, and in many cases reduces the fragility you get with external adapters.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Dual IEEE 1394b ports (9‑pin) – Connect up to two FireWire 800 cameras; backward compatible with IEEE 1394a in many cases.

- Up to 800 Mb/s link speed – Suitable for moderate-resolution area-scan or line-scan image acquisition without taxing the CPU.

- PXI integration – Leverages the PXI backplane for timing, power, and a compact footprint; cleaner than external adapters.

- NI-IMAQdx support – Works with DCAM/IIDC cameras in LabVIEW and Vision Development Module, which simplifies camera control and image streams.

- Deterministic test setups – PXI backplane timing resources help coordinate cameras with other I/O in the chassis.

- Field-proven with legacy cameras – Ideal when maintaining validated 1394 imaging assets or long-life equipment.

Technical Specifications

| Brand / Model | NI PXI-8252 |

| HS Code | 8471.80 (Units of automatic data processing machines) |

| Form Factor | 3U PXI, single-slot module; front-panel 9‑pin IEEE 1394b connectors |

| Power Requirements | Powered from PXI backplane (5 V / 3.3 V rails). No external PSU required for the board. |

| Operating Temperature | Typically 0 °C to 55 °C, non‑condensing (standard NI PXI range) |

| Signal I/O Types | 2 × IEEE 1394b (FireWire 800) ports; backward compatible with IEEE 1394a devices and cables where supported |

| Communication Interfaces | IEEE 1394b to cameras; PXI backplane to host controller |

| Installation Method | Install into a compatible 3U PXI chassis slot; secure with captive screws; connect 9‑pin 1394b cables to cameras |

| Software / Driver | NI-IMAQdx with NI Vision software; supports IIDC/DCAM compliant FireWire cameras |

Related or Supporting Products

- NI PCI-8252 – PCI version of the same IEEE 1394b interface for desktop PCs; useful when a PXI chassis isn’t required.

- NI PXI-8254R – IEEE 1394b interface with onboard reconfigurable FPGA, typically chosen for custom timing/trigger logic at the interface level.

- NI PCIe-8237R – GigE Vision alternative with FPGA acceleration; for teams migrating away from FireWire to GigE Vision cameras.

- Industrial IEEE 1394b (9‑pin to 9‑pin) shielded cables – Various lengths; choose quality cables for reliable 800 Mb/s links.

- PXI controllers and chassis – PXI-Express or PXI controllers compatible with NI-IMAQdx and Vision Development Module.

From my experience, customers keeping legacy 1394 line-scan cameras often pick PXI-8252 to extend system life 3–5 years while planning a gradual camera standard change. One customer noted “we swapped a USB dongle setup with PXI-8252 and stability improved right away, especially during long overnight runs”.

Installation & Maintenance

- Cabinet / Chassis – Use a compliant PXI chassis with adequate ventilation; keep intake/exhaust clear to maintain the typical temperature range.

- Wiring – Use high-quality 9‑pin IEEE 1394b cables; avoid sharp bends and mixed cable lengths that can invite marginal link behavior at 800 Mb/s.

- Power to cameras – Some 1394 cameras draw bus power; check camera current draw versus your chassis power budget before enabling bus power.

- Triggering & sync – Where low jitter is required, use PXI timing resources and keep cable runs short; confirm DCAM camera settings in NI-IMAQdx.

- Routine care – Inspect connectors quarterly, clean dust from the front panel, and keep NI-IMAQdx/Vision software up to date for camera compatibility.

- Handling – IEEE 1394 supports hot-plug, but I typically recommend connecting with power off on production lines to minimize inrush or ESD surprises.

Quality & Certifications

- CE and RoHS compliant; designed for industrial EMC environments (EN 61326 family, typical for NI PXI modules).

- UL/CSA safety evaluated for PXI modules where applicable.

- Manufacturer’s standard warranty: typically 1 year; we provide a 365‑day warranty window on supply.

- Traceable sourcing and test documentation available upon request.

Reviews

There are no reviews yet.