Description

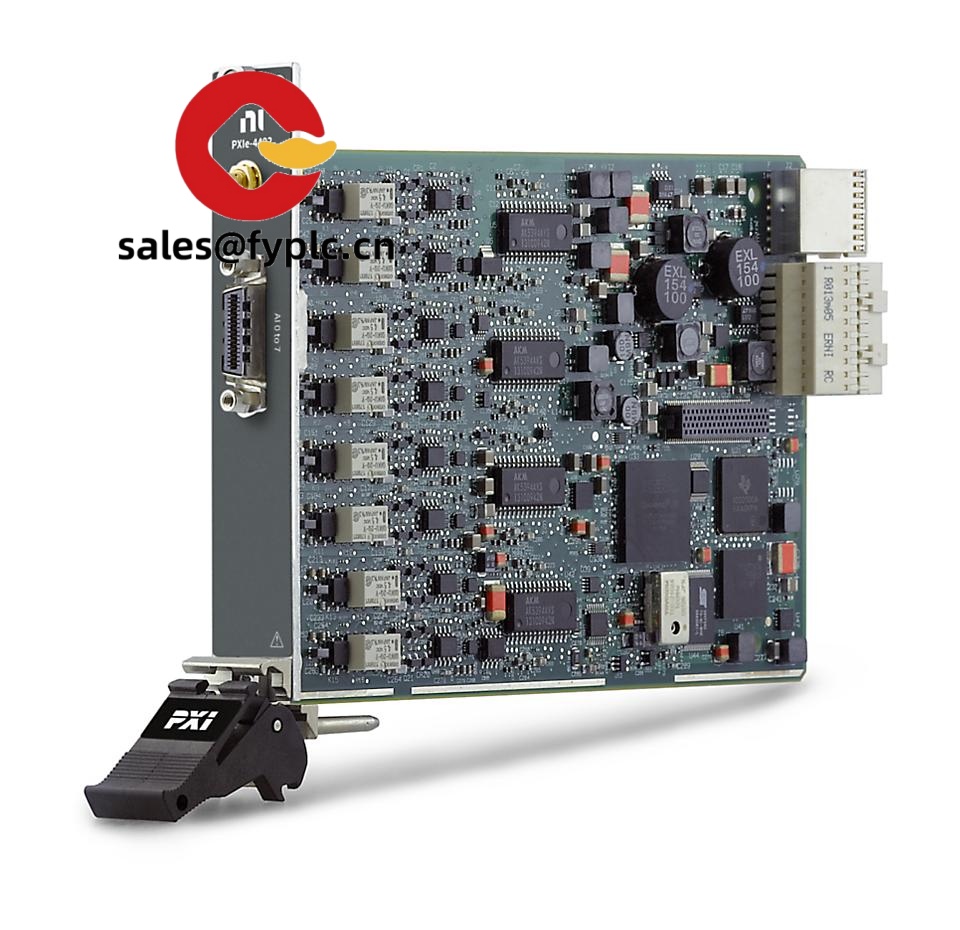

NI PXIe-4080 – 6.5‑Digit PXI Express Digital Multimeter for Automated Test

The NI PXIe-4080 is a 6.5‑digit PXI Express digital multimeter designed for production test, validation labs, and mixed-signal ATE. From my experience, it fits best when you need precision DC/AC measurements and tight synchronization with other PXI instruments without adding external boxes or extra cabling. You might notice that it speeds up test development because it uses the standard NI‑DMM driver and integrates cleanly with LabVIEW, TestStand, and common PXI switching modules.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 6.5‑digit precision – Suitable for bench-level accuracy in automated systems, typically covering DC/AC voltage and current, resistance, frequency/period, and diode tests.

- PXI Express integration – Tight timing and triggering with other PXI/PXIe modules reduces test overhead and helps you parallelize steps.

- Fast measurement throughput – Optimized measurement apertures and driver-level buffering help cut test times in production lines.

- NI‑DMM driver support – Stable APIs for LabVIEW and other NI environments; in many cases, existing PXI DMM code ports with minimal edits.

- System-friendly I/O – Front-panel DMM input connector supports common functions, and it works neatly with PXI switch matrices for multi-point scans.

- Ideal use cases – Power supply test (ripple and regulation), sensor characterization (temperature, pressure bridges via resistance), PCB functional test, and maintenance/calibration stations.

Technical Specifications

| Brand / Model | NI PXIe-4080 |

| HS Code | 9030.31 (digital multimeters) |

| Measurement Resolution | 6.5 digits (typical DMM functions) |

| Power Requirements | Powered from PXI Express backplane; no external supply required |

| Dimensions & Weight | 3U PXI Express, 1‑slot module; depth approx. 160 mm |

| Operating Temperature | 0 °C to 55 °C (typical for NI PXI modules) |

| Signal Input/Output Types | DC/AC V, DC/AC I, 2‑wire/4‑wire resistance, diode, frequency/period (via front-panel DMM input connector) |

| Communication Interfaces | PXI Express backplane; PXI trigger lines for synchronization; software via NI‑DMM driver |

| Installation Method | Installs in a 3U PXI Express chassis; use appropriate NI terminal block/cabling for the DMM front connector |

| Software Compatibility | NI‑DMM; works with LabVIEW, TestStand, and common NI drivers |

Related and Supporting Products

- NI PXIe-4081 – Higher‑resolution DMM (typically 7.5‑digit) for tighter accuracy; tradeoff is usually slower high‑precision apertures.

- NI PXIe-4082 – DMM with added LCR measurement capability; handy when you need impedance/capacitance/inductance in the same slot.

- NI PXI-4070 – Legacy 6.5‑digit DMM (PXI, not Express); useful as a drop‑in for older PXI systems.

- Chassis/Controller options – NI PXIe-1085 chassis and NI PXIe-8880 controller are commonly paired for high‑throughput test stations.

- Switching – PXI matrix/relay modules (for example, PXI/PXIe switch families) to route multiple DUT points to the DMM for automated scanning.

Installation & Maintenance

- Environment – Install in a 3U PXI Express chassis with adequate airflow. Keep intake/exhaust paths clear; in most cases, 10 cm clearance is enough for stable cooling.

- Wiring – Use properly rated, shielded leads for AC measurements and high‑impedance resistance work. Ensure correct terminal mapping when using a PXI switch to avoid open‑circuit readings.

- Safety – Observe input limits and isolation practices for the DMM front end. De‑energize the DUT before re‑wiring. Use proper fusing on current ranges if applicable.

- Routine care – Clean front connectors periodically with dry, lint‑free swabs. Verify zero/offset on sensitive ranges after long warm‑ups.

- Calibration – Annual calibration is typical for production lines; high‑accuracy labs may schedule 6–12 month intervals depending on QA requirements.

- Firmware/Driver – Keep NI‑DMM and chassis firmware current. You might notice stability improvements and faster ranging behavior with newer driver releases.

Quality & Certifications

- CE compliant

- RoHS compliant

- Manufactured under ISO 9001 quality systems

- Supplier warranty: 365 days as stated above

One thing I appreciate is how the PXIe-4080 scales: if your test plan grows, you can synchronize multiple DMMs with PXI triggers and add switching to cover dozens of points without re‑architecting the rack. Customers typically comment that migration from older PXI DMMs takes less time than expected, mainly because the driver calls and channel models feel familiar.

Reviews

There are no reviews yet.