Description

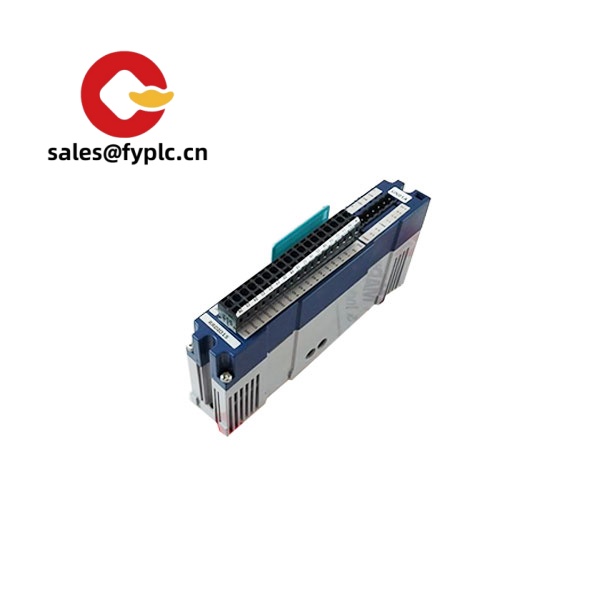

KONGSBERG RPC420 – 4–20 mA Remote Process/Control Interface for Marine and Industrial Systems

The KONGSBERG RPC420 is commonly deployed as a robust 4–20 mA interface module within propulsion, thruster, DP, and alarm/monitoring cabinets. From my experience, it’s selected when you need clean, isolated current-loop I/O that can live comfortably in a marine-grade control environment. You might notice that it slots neatly into cabinet layouts with 24 VDC supplies and provides reliable signal integrity over long cable runs—exactly what many engine rooms and control rooms require.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: typically 1 week for in-stock items; no more than one month at the latest

- Payment method: 50% advance payment; full payment prior to delivery

- Express delivery options: FedEx, UPS, DHL

We normally confirm the exact RPC420 revision and I/O configuration against your cabinet BOM before invoicing, which avoids mismatches in connectors or firmware. A quick photo of the module nameplate usually speeds things up.

Key Features

- 4–20 mA signal handling – Stable current-loop I/O for valves, actuators, pressure/level transmitters, and propulsion feedback where noise immunity matters.

- Galvanic isolation – Typically isolated channels help cut ground-loop issues and improve EMC behavior in mixed-signal cabinets.

- Marine-grade design – Built for use in maritime control systems; appears to follow practices aligned with IEC 60945 environments in many cases.

- Diagnostics and status indication – Front indicators (where fitted) make loop checks and fault tracing quicker during commissioning.

- Cabinet-friendly 24 VDC ecosystem – Designed to run on standard 24 VDC control power, easing integration with existing power distribution.

- Flexible control integration – Typically interfaces to a host controller via serial backplane or cabinet bus, depending on system architecture.

Technical Specifications

| Brand / Model | KONGSBERG RPC420 |

| HS Code | 8537.10 (Boards/panels for electric control, for a voltage not exceeding 1,000 V) |

| Power Requirements | 24 VDC nominal (18–32 VDC typical for control cabinets) |

| Operating Temperature | -15 °C to +55 °C (typical marine cabinet range; confirm against the product nameplate) |

| Signal Input/Output Types | 4–20 mA analog I/O; discrete digital I/O may be present depending on configuration |

| Communication Interfaces | Typically cabinet/backplane bus or RS-422/RS-485 to host controller (varies by system) |

| Installation Method | Cabinet-mounted (DIN rail or backplate), shielded cabling recommended for long runs |

Note: Channel count and exact I/O mix can differ by RPC420 revision and application cabinet. We’re happy to verify against your drawing set or spare parts list.

Related or Supporting Products

- 24 VDC Marine Power Supply – e.g., PULS DIMENSION QS10.241. Stable feed for control modules; low ripple and high MTBF.

- Signal Isolators for 4–20 mA – e.g., Phoenix Contact MCR series. Added isolation when loops run across different grounding zones.

- RS-485/RS-422 Device Server – e.g., Moxa NPort 5150A. Useful when bridging serial cabinet buses to Ethernet for remote diagnostics.

- Shielded 4–20 mA Cable – Twisted-pair, tinned copper with overall foil/braid shield to improve EMC immunity in engine rooms.

- Panel Accessories – DIN rail earth terminals, ferrules, and gland plates that keep cabinet wiring tidy and serviceable.

If you’re replacing a legacy 4–20 mA interface in a KONGSBERG-controlled system, we can cross-check the RPC420 against the existing module code and firmware notes. In many cases, firmware alignment and simple re-scaling are all that’s needed to drop in the new unit.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry control cabinet with adequate ventilation. Maintain clearances for heat dissipation and cable bend radius.

- Power and grounding – Use a regulated 24 VDC supply with proper PE bonding. Star-earthing techniques typically reduce noise and ground loops.

- Wiring practices – Route analog 4–20 mA pairs away from high-current motor cables. Use shielded twisted-pair; terminate shields at one end to avoid loops.

- Loop commissioning – Perform loop checks with a current calibrator; verify scaling and any alarm thresholds in the host controller.

- Routine maintenance – Periodic visual inspection for loose terminals, dust build-up, or moisture ingress. Re-torque terminals annually and clean with non-conductive wipes.

- Firmware/configuration – Where applicable, back up configuration before updates. It’s usually safer to align firmware with the rest of the cabinet spare parts strategy.

- Safety – De-energize the cabinet before installation or service. Follow LOTO procedures and local marine safety rules.

Quality & Certifications

- CE-compliant; RoHS alignment typical for current production

- Marine type approvals are commonly available for KONGSBERG control modules (DNV, ABS, LR); confirm per module revision

- Manufacturer’s policy generally provides dependable lifecycle support for critical spares in control cabinets

- 365-day warranty from our side on supplied units

Reviews

There are no reviews yet.