Description

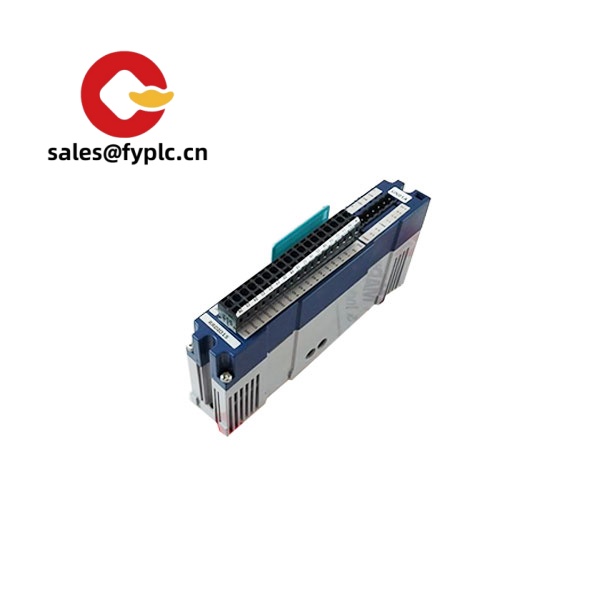

ROLLS-ROYCE RRDIO15 – Compact Digital I/O Module for Turbine, Genset, and Marine Control Systems

The ROLLS-ROYCE RRDIO15 is a compact digital I/O module typically used in engine and power-system control cabinets where robust, isolated signals are a must. From my experience, it fits well in retrofit and expansion scenarios—adding discrete inputs/outputs for interlocks, status signals, and solenoid/relay drives around turbines, generator sets, or propulsion packages. One thing I appreciate is the straightforward wiring and diagnostics, which makes maintenance teams more confident during tight service windows.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 15-channel digital I/O – Typically configured as discrete inputs and outputs for alarms, interlocks, permissives, and control relays.

- 24 VDC field signals – Suited for standard industrial 24 VDC contact/PNP/NPN wiring used around engines and auxiliary skids.

- Galvanic isolation – Channel-to-bus isolation helps protect the controller from field transients and wiring faults.

- Status LEDs per channel – You might notice how quickly issues are narrowed down just by checking the front indicators.

- Compact DIN-rail footprint – Fits neatly in crowded cabinets; pluggable terminal blocks typically speed up swap-outs.

- Industrial temperature range – Designed for control rooms and machinery spaces where ambient swings happen.

- Diagnostics-friendly – In many cases supports simple loop checks and commissioning via visible I/O state feedback.

- Stable 24 VDC power – With reverse polarity and transient protection commonly included to extend service life.

Technical Specifications

| Brand / Model | ROLLS-ROYCE RRDIO15 |

| HS Code | 8537.10 (Boards/panels/consoles for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal (typ. 18–32 VDC input), module consumption ~4–6 W |

| Signal Input/Output Types | Up to 15 digital channels; common setups are mixed DI/DO at 24 VDC; transistor outputs typically up to 0.5 A/channel (use interposing relays for higher loads) |

| Communication Interfaces | Backplane/system bus in RR control racks or RS‑485 (Modbus RTU) depending on variant |

| Installation Method | DIN-rail mounting in control cabinet; pluggable terminal connectors for field wiring |

| Operating Temperature | Typically −20 °C to +60 °C (cabinet-installed) |

| Dimensions & Weight | Approx. 100 × 120 × 35 mm; ~0.35 kg (DIN-rail module class) |

Notes: Specs reflect common configurations seen in service. Variants exist by system build; confirm final I/O mapping and interface at order stage.

Related or Supporting Products

- ROLLS-ROYCE RRDIO08 – Lower-density 8‑channel digital I/O for small panels or limited point counts.

- ROLLS-ROYCE RRDIO32 – High‑density digital I/O where cabinets need more discrete points per rail.

- ROLLS-ROYCE RRAI08 – 8‑channel analog input module (typ. 4–20 mA/0–10 V) for process feedback.

- ROLLS-ROYCE RRAO04 – 4‑channel analog output module for actuator and speed/governor controls.

- ROLLS-ROYCE RRPS-24V – 24 VDC power supply sized for I/O loads with surge reserve.

- ROLLS-ROYCE RRCOM-485 – Communication gateway for bridging to RS‑485/Modbus plant networks.

Installation & Maintenance

- Cabinet & environment – Mount inside a sealed control cabinet (IP54 or better is common); allow airflow or passive ventilation around the module.

- Wiring practice – Separate 24 VDC I/O wiring from power and high‑noise cables; use ferrules and label each point. Shielded cable for long runs typically reduces false transitions.

- Grounding – Tie shields at a single point; ensure cabinet ground is low impedance to avoid nuisance trips.

- Protection – Add appropriately rated fuses/breakers for the module’s 24 V feed; interpose relays for inductive or high current loads.

- Commissioning – Use the channel LEDs for quick loop checks; verify DI logic (sourcing/sinking) and DO polarity before energizing.

- Routine care – Quarterly dust-out in dusty environments, check terminal torque, and review event logs. Firmware/config updates should follow site change-control, where applicable.

- Service anecdote – A maintenance lead told us they swapped an RRDIO15 in under 10 minutes during a genset outage window, thanks to the pluggable terminals and clear channel labeling.

Quality & Certifications

- CE conformity (EMC and Low Voltage directives)

- RoHS-compliant materials

- Designed to meet typical industrial safety standards such as UL/IEC for control equipment

- Manufacturing under ISO 9001 quality systems

- Standard warranty: 365 days

If your application mixes safety interlocks with high‑density alarm points, the RRDIO15 seems to balance footprint and channel count nicely. You’ll usually get fast diagnostics, predictable 24 VDC behavior, and a clean installation on DIN rail—without reworking the whole cabinet layout.

Reviews

There are no reviews yet.