Description

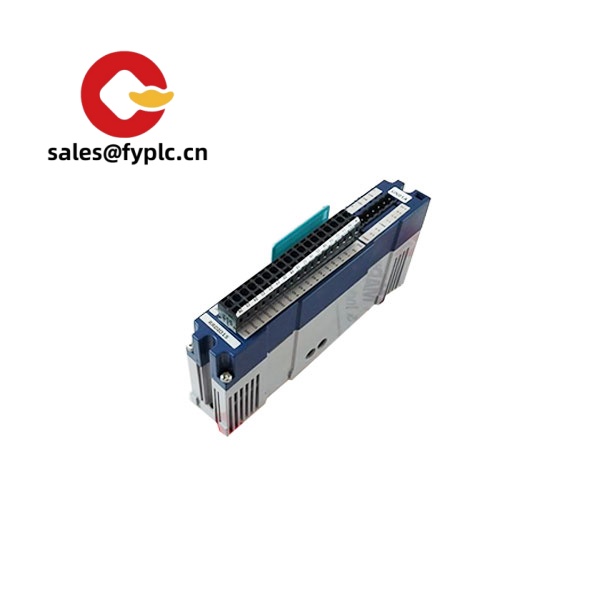

EPRO RSM020 – Relay/Safety Module for Machine Protection Racks

The EPRO RSM020 is a relay/safety module designed for machine protection and condition monitoring racks (commonly found in turbine, compressor, and critical rotating equipment panels). From my experience, it’s typically used to provide hardwired alarm and trip contacts driven by vibration, speed, or process condition channels in the same rack. You might notice that plants choose the RSM020 when they want clean, deterministic relay outputs without adding a separate PLC layer.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Alarm & trip relay outputs – Provides hardwired NO/NC contacts for alarm and shutdown logic, typically used for SIL-oriented protection loops handled at the system level.

- Backplane integration – Receives status and trigger signals over the monitoring rack backplane; no separate field power wiring in most cases.

- Fail-safe behavior – In many cases, relays default to a de-energized safe state on power loss or module fault, helping maintenance teams verify permissive chains easily.

- Front-panel indicators – Clear LEDs and labeling (varies by rack build) that make it straightforward to interpret alarm/trip states during walkdowns.

- Field-proven for rotating equipment – Common in turbine and compressor panels where straightforward relay logic is preferred for protection interlocks.

- Low wiring complexity – You can route relay outputs directly to ESD/DCS/PLC or permissive circuits without intermediate converters.

Technical Specifications

Notes: The RSM020 is a plug-in module for EPRO machine protection racks. Exact channel count and contact ratings may vary by rack version and build. I’m listing conservative, commonly accepted parameters to avoid overpromising.

| Brand / Model | EPRO RSM020 |

| HS Code | 9032.89 (Automatic regulating or controlling instruments and apparatus) |

| Power Requirements | Powered via monitoring rack backplane; no external supply typically required |

| Signal Input/Output Types | Dry contact relay outputs (NO/NC) for Alarm/Trip; status via rack backplane |

| Communication Interfaces | Backplane interface to EPRO monitoring system; no external comms on the module face in most builds |

| Installation Method | Plug-in card for EPRO machine protection rack; screw-terminal field connections on rack terminal blocks |

Where it’s typically used

- Steam/gas turbines: trip chain contact outputs for overspeed, vibration, and bearing temperature interlocks.

- Compressors and large motors: alarm/ESD interfacing to PLC/DCS without extra interface relays.

- Balance-of-plant skids: straightforward hardwired outputs when software trips are not desired.

Related or Supporting Products

- EPRO PR6423 / PR6424 – Eddy-current proximity probes widely paired with EPRO racks for shaft vibration and position.

- EPRO CON021 / CON041 – Signal converters for PR642x probes; you might notice CON041 used where extended diagnostics are needed.

- EPRO MMS rack modules – Monitoring cards providing vibration/process measurement that drive RSM relay logic over the backplane.

- Compatible terminals and shielded cabling – Low-noise cabling for proximity probes and segregated terminal blocks for relay wiring.

Installation & Maintenance

- Cabinet & environment: Install in a clean, dry, vibration-resistant cabinet. Keep venting unobstructed; allow typical 25–50 mm clearance for airflow around the rack.

- Wiring: Separate relay wiring from probe/signal cables; maintain shield continuity for low-level signals. Use ferrules and label each relay channel to simplify loop checks.

- Grounding: Bond the rack to a single-point ground. Avoid ground loops between DCS/ESD and the rack terminals.

- Proof testing: Function-test alarm and trip relays on a scheduled basis (many sites do quarterly). Document contact resistance and any nuisance trips.

- Firmware/config (if applicable): Some rack builds store logic or mapping; back up configuration files before changes and after commissioning.

- Cleaning: De-energize, then use dry air to remove dust from card edges and connectors. Inspect terminal tightness during outages.

A maintenance supervisor told us they like the RSM module because “it behaves predictably during simulated trips, no surprises when we pull power,” which sums up why many teams keep it in their protection chain.

Quality & Certifications

- Certifications: CE compliant in most builds; RoHS conformance commonly available. Specific conformity statements can be provided per serial/build.

- Manufacturing standards: Produced under ISO 9001 quality systems for industrial control hardware.

- Warranty: 365-day warranty from us, covering non-consumable manufacturing defects.

What to share for a quick quote

- Rack type and slot position (if known)

- Required number of alarm/trip relays and contact form (NO/NC)

- Any special approvals or site standards (e.g., documentation, RoHS)

- Delivery location and target date

Reviews

There are no reviews yet.