Description

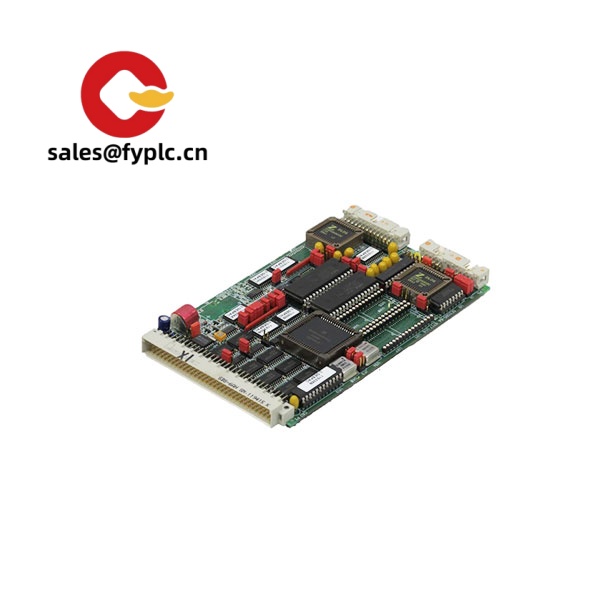

ABB SB511 (3BSE002348R1) – Interface/Link Module for System 800xA Cabinets

The ABB SB511 (3BSE002348R1) is typically used as a compact interface/link module inside System 800xA and AC 800M-based panels. From my experience, it’s selected where engineers need a stable, cabinet-friendly way to bridge controller-side signals to I/O networks or supporting subassemblies without adding a full communication processor. You might notice that its strengths are reliability, tidy wiring, and straightforward diagnostics—exactly the things that keep a process unit running when production is tight.

In many cases it’s deployed alongside S800 I/O and controller hardware to extend or adapt signals on the panel side. One thing I appreciate is how it slots into existing ABB control architectures with minimal fuss: standard 24 VDC power, DIN-rail friendly footprint, and clear status indication for quick checks during startup or maintenance.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In-stock typically ships in 1 week; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express Options: FedEx, UPS, DHL

Key Features

- Panel-friendly 24 VDC design – Fits standard control cabinets; wiring and power budgeting stay simple.

- Stable signal interfacing – Designed to work reliably in ABB 800xA/AC 800M environments, reducing nuisance faults.

- LED status indicators – Quick visual diagnostics for commissioning and fault tracing, typically saving technician time.

- DIN-rail mounting – Streamlines assembly and service access inside compact panels.

- Industrial temperature range – Built for typical plant conditions; holds up well in most MCC and DCS cabinets.

- Low maintenance – No moving parts; periodic checks and firmware alignment (where applicable) are usually all that’s needed.

Technical Specifications

| Brand / Model | ABB SB511 – 3BSE002348R1 |

| HS Code | 8537.10 (Programmable control/industrial control apparatus) |

| Power Requirements | 24 VDC nominal (typical), low power consumption suitable for cabinet rails |

| Dimensions & Weight | Compact DIN-rail footprint; lightweight module for dense panels (typical S800 I/O-scale form factor) |

| Operating Temperature | 0 to +55 °C (typical for cabinet-mounted ABB modules) |

| Signal I/O Types | Interface/link functions within ABB 800xA/AC 800M systems (used to bridge/route signals at panel level) |

| Communication Interfaces | Cabinet-side interface as per SB511 application; integrates with ABB controller/I&O backplane environment |

| Installation Method | DIN-rail mounting; front-access connectors and status LEDs for quick service |

Related or Supporting Products

- ABB CI854A (3BSE030220R1) – PROFIBUS DP-V1 interface for AC 800M; used when field devices are on DP networks.

- ABB CI853 (3BSE018135R1) – DeviceNet communication for AC 800M; suitable for brownfield upgrades with DeviceNet.

- ABB TB810 / TB821 – ModuleBus optical/extension components for S800 I/O when distance or noise immunity is a concern.

- ABB TU8xx Series – Termination units for S800 I/O modules; match the I/O type and wiring style.

- ABB PM86x/PM87x Controllers – AC 800M CPUs that host the control application; pair depending on performance and redundancy needs.

If you’re replacing an older cabinet interface or rationalizing a mixed-vendor panel, SB511 typically drops in cleanly. A maintenance lead at a chemicals site told us it cut their cabinet troubleshooting time because the front diagnostics were “obvious even for night shifts.”

Installation & Maintenance

- Cabinet environment – Install on DIN-rail inside a clean, ventilated enclosure; keep ambient within 0–55 °C and avoid heat hotspots near power supplies.

- Grounding and shielding – Bond the DIN-rail to cabinet earth. Use shielded signal cables where applicable and terminate shields at one end to limit ground loops.

- Wiring – Maintain clear separation between power and signal wiring. Label both sides; keep service loops minimal for better EMC behavior.

- Redundancy and layout – Where uptime is critical, plan power redundancy and route critical links on separate cable paths.

- Routine checks – Visually inspect connectors quarterly, verify LED/status behavior, and confirm configuration alignment after controller firmware updates.

- Cleaning – Dust with dry air at low pressure; avoid solvents. Re-torque terminal screws if the site has high vibration.

- Firmware/config – If the SB511 setup is managed via the control system, keep configuration backups; validate after PLC or 800xA updates.

Quality & Certifications

- Certifications: CE; typically used in UL-listed control panels; RoHS-compliant components are commonly used across ABB 800xA module families.

- Manufacturing quality: Built to ABB’s ISO 9001 quality system standards for industrial control hardware.

- Warranty: 365 days replacement/repair policy as stated above.

If you’re aligning the SB511 with a specific controller or S800 I/O combination, share the cabinet layout or existing module list—matching the interface and power budget up front typically saves time during FAT and commissioning.

Reviews

There are no reviews yet.