Description

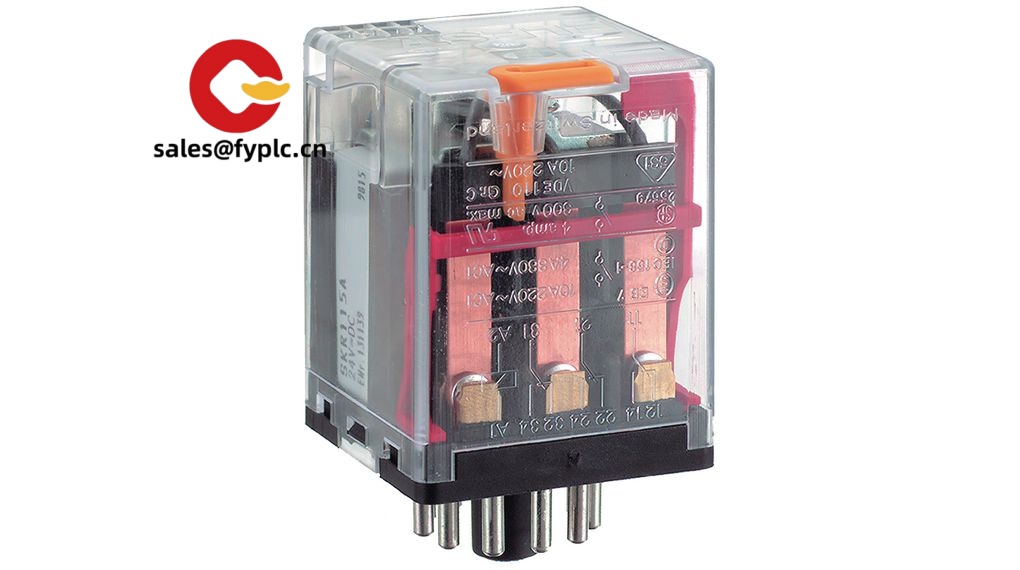

Allen‑Bradley SKR115A – Compact Control Relay for Interlocks and General Industrial Control

The Allen‑Bradley SKR115A is commonly used as a compact control relay in panels where reliable interlocking, status logic, or auxiliary control is needed. From my experience, it’s typically selected when you want a straightforward, DIN‑rail friendly relay with a 115 V AC coil that you can drop into existing Rockwell Automation panels without surprises. You might notice that it shows up in motor starter cabinets, safety gate circuits (non‑safety rated portions), and simple on/off interlocks where clean, mechanically linked contacts matter.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Traceability: factory-sealed or fully tested units with photos before shipment

- Packaging: ESD-safe, shock‑absorbing, moisture protection for long transit routes

Key Features

- 115 V AC coil (50/60 Hz) – Suits legacy and new panels that standardize on 110/115 VAC control power.

- DIN‑rail friendly footprint – Typically 22.5 mm wide format that keeps cabinets tidy and serviceable.

- Mechanically linked contacts – In many cases used to build interlocks or feedback chains that need dependable state tracking.

- Clear status indication – Most builds include coil status indication so technicians can fault‑find quickly.

- Rockwell ecosystem fit – Pairs well with Allen‑Bradley starters, contactors, and terminal blocks for neat wiring and documentation.

- Panel‑builder friendly terminals – Typically screw or spring terminals with clear marking to reduce wiring errors.

Technical Specifications

| Brand / Model | Allen‑Bradley SKR115A |

| HS Code | 8536.49.00 (Industrial control relays) |

| Power Requirements (Coil) | 115 V AC, 50/60 Hz (typical for this build code) |

| Signal I/O Types | Electromechanical relay contacts (e.g., mixed NO/NC); commonly used for interlock/control circuits |

| Communication Interfaces | None (discrete relay) |

| Installation Method | 35 mm DIN‑rail; front‑access terminals |

| Operating Temperature | Typically −25 °C to +55 °C (panel‑mounted, non‑condensing) |

| Dimensions & Weight | Approx. 22.5 mm width, compact relay form factor; light weight for dense cabinets |

Note: The SKR115A designation typically denotes a 115 V AC coil variant in the Allen‑Bradley control relay family. If you share a photo of the nameplate or terminals, we can confirm contact configuration (e.g., NO/NC mix) before shipping.

Related or Supporting Products

- Allen‑Bradley 700‑H and 700‑S series relays – alternative contact configurations and ratings if you need different pole counts.

- Allen‑Bradley 1492 terminal blocks – tidy wiring and jumpers for interlock chains.

- Allen‑Bradley 1606 power supplies – stable 24 V DC rails where you’re mixing AC and DC control.

- Allen‑Bradley 100‑C contactors – pair with the relay for motor starter logic and feedback circuits.

Installation & Maintenance

- Panel/Cabinet: Mount on 35 mm DIN rail in a ventilated enclosure; keep ambient within spec and away from vibration hotspots.

- Wiring: Use correctly sized ferruled conductors; torque terminals per Rockwell guidance; segregate control from power wiring.

- Protection: Provide overcurrent protection on the coil feed; add surge suppression where switching inductive loads.

- Commissioning: Verify coil voltage (115 VAC) before energizing; perform a contact continuity check on NO/NC paths.

- Routine checks: Function‑test during planned downtime; inspect terminals for loosening and discoloration; replace if contact wear is observed.

- Documentation: Label the relay on the DIN rail; keep the wiring diagram updated for faster troubleshooting.

Quality & Certifications

- Manufacturing standards: typically CE and cULus for industrial control equipment; RoHS compliant builds available.

- Manufacturer’s policy: standard Rockwell warranty; we extend a 365‑day warranty on supply.

- Each unit is inspected and, in many cases, electrically tested prior to dispatch.

Reviews

There are no reviews yet.