Description

I. Basic Information Positioning

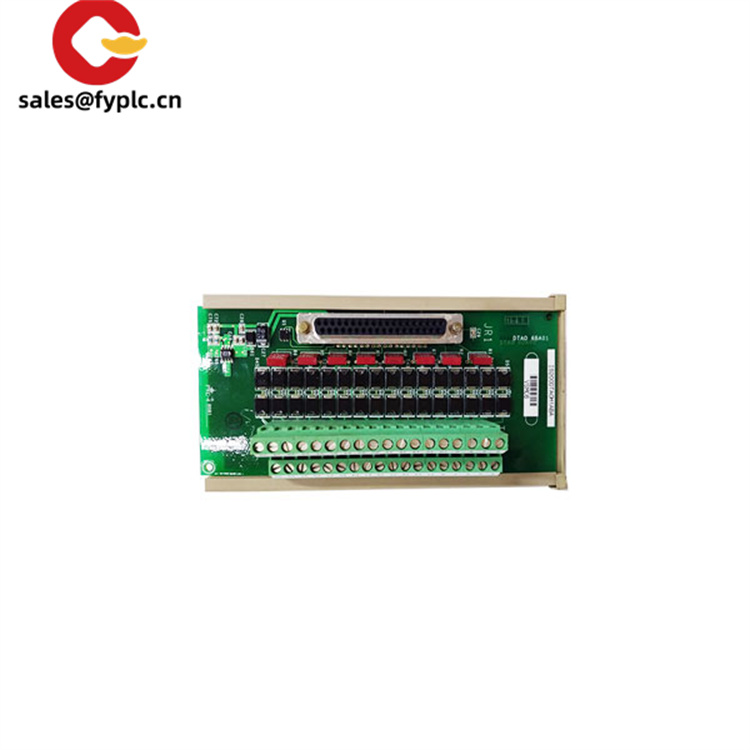

Model: IS200DTAOH1ABA

Brand/Series: General Electric (GE) Mark VIe Turbine Control System

Module type: Digital Output Module (DO module)

Core function: Convert the digital signals of the controller into drive signals for field devices (such as relay contact output), which is used in industrial automation control scenarios (such as turbine and actuator control in energy systems).

Ii. Hardware Design and Interface Speculation

1. Appearance and structure

Size: Standard rack-mounted module, backplane slot compatible with the Mark VIe system (usually 1U in height, with the same width as other modules).

Front panel

Status indicator lights: Power Supply (PWR), Module Ready (RDY), Fault Alarm (ALM), output status of each channel (LED light).

Reset button (optional) : Used for restarting after module failure.

Back interface:

Bus interface: Communicate with the Mark VIe controller through the backplane (such as the SERCOS bus).

Power interface: 24V DC input (It may share the power supply with the input module, but the manual needs to be confirmed).

Signal terminal block: It is used to connect field devices (such as relays, solenoid valves, contactors, etc.).

2. Output channel characteristics

The number of channels: The IS200DTAOH1ABA commonly has 16 digital output channels (DO) (for modules of the same series, such as the IS200DTAIH1ABB, the input module has 16 input channels. It is speculated that the number of output module channels matches).

Output type:

Relay output: Supports AC and DC loads (such as 250V AC/30V DC, maximum current 2A/channel), with electrical isolation, suitable for driving strong electrical equipment.

Solid state relay (SSR) output: Some models may adopt (such as DC 24V/1A), with a fast response speed but relatively low load capacity (confirmation based on the model is required).

Isolation characteristics: Electrical isolation between channels (isolation voltage ≥500V AC) to prevent interference between channels.

Iii. Speculation on Technical Specifications

Power supply voltage: 24V DC (±10%)

Output current: Maximum 2A per channel (relay type)

Switching frequency: Relay type: ≤10Hz; Solid-state type: ≥1kHz

Operating temperature: -40°C to 85°C (industrial-grade wide-temperature design

Anti-interference level: Complies with EMC standards (such as EN 61000-6-2/6-4)

Installation method: Vertically insert into the Mark VIe rack, hot plugging is supported (for some models)

Iv. Analysis of Functional Features

Reliability design

Fault Diagnosis: The IS200DTAOH1ABA supports channel-level fault detection (such as output short circuit and open circuit). When a fault occurs, it will alarm through indicator lights and system software.

Surge protection: Built-in freewheel-following diode or varistor to suppress the counter electromotive force when inductive loads (such as motors, solenoid valves) are disconnected, protecting the module.

Fail-safe mode: It may support “power-off hold” or “power-off reset” mode (which needs to be configured through software) to ensure the output status is safe when the system malfunctions (such as keeping the valve closed when the machine stops).

2. Configuration and Communication

Software configuration: Set the output logic (such as positive logic/negative logic, pulse output time), channel grouping, etc. through GE dedicated software (such as Proficy Machine Edition).

Communication protocol: IS200DTAOH1ABA communicates with the controller in real time through the Mark VIe backplane bus, supporting a data refresh rate of ≤10ms (meeting the requirements of high-speed control).

Redundancy support: Some models may support dual-bus redundancy (requiring a redundancy controller) to enhance system reliability.

3. Industrial applicability

Environmental tolerance: Anti-vibration (in compliance with IEC 60068-2-6), anti-shock (in compliance with IEC 60068-2-27), suitable for the harsh environment at turbine sites.

Certification compliance: It may pass UL, CE, ATEX (explosion-proof) and other certifications, meeting the standards of different industries.

V. Typical Application Scenarios

Energy and Electricity

Valve control of gas/steam turbines (such as the opening and closing of intake valves and exhaust valves).

Start-stop control of generator auxiliary equipment (such as lubricating oil pumps and cooling fans).

Industrial automation

Logical control of production line equipment (such as the start and stop of conveyor belts and the operation of cylinders).

Alarm output in process control (such as connecting sound and light alarms).

Petrochemical industry

Safety interlock control of reactors and storage tanks (such as emergency shut-off valve drive).

Remote control and status feedback of pump sets and compressors.

| GE | IS200BPIAG1A |

| GE | IS200BLIGH1A |

| GE | IS200BICRH1A |

| GE | IS200BICMH1A |

| GE | IS200BICLH1B |

| GE | IS200BICLH1A |

| GE | IS200BICHH1A |

| GE | IS200BCI h1BBC |

| GE | IS200BAIAH1B |

| GE | IS200AVIFH1A |

| GE | IS200AEPCH1BAA |

Reviews

There are no reviews yet.