Description

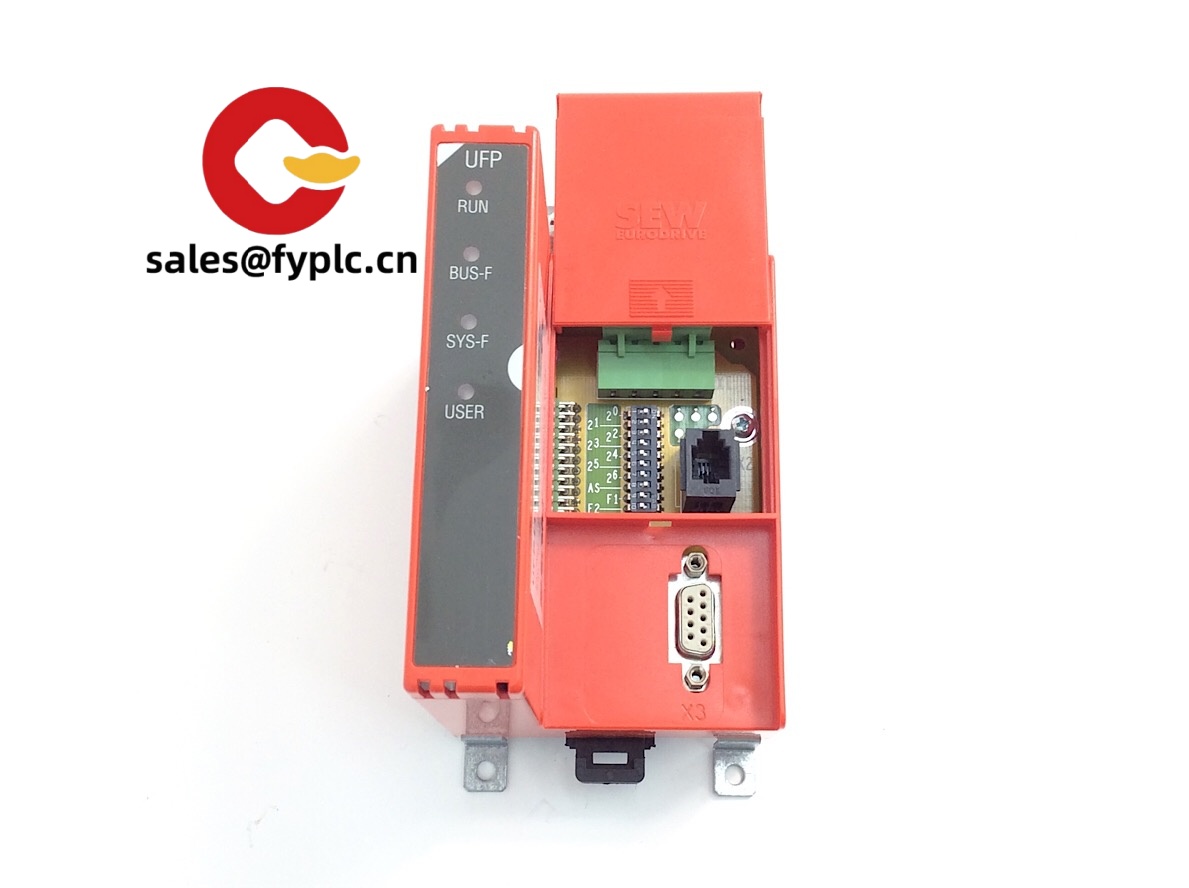

SEW‑EURODRIVE UFP11A-00 – PROFIBUS-DP fieldbus option for legacy MOVIDRIVE applications

The SEW‑EURODRIVE UFP11A‑00 is a plug-in PROFIBUS‑DP interface module typically used on earlier MOVIDRIVE A‑series installations to bring the drive cleanly onto a PLC network. If you’re keeping a proven line running and just need the drive talking reliably over PROFIBUS, this little card does the heavy lifting—no external power, no fuss. One thing I appreciate is the straightforward 9‑pin Sub‑D connection and auto‑baud detection, which, in many cases, means you drop it in, set the address, load the GSD, and you’re online.

From my experience, plants value the UFP11A‑00 when they’re maintaining mixed generations of SEW drives. It keeps the older MOVIDRIVE units in step with modern PLCs without reworking the cabinet. A maintenance lead at a beverage facility told us they swapped in a UFP11A‑00 on an MDX60 unit and had the node healthy on the DP ring in under ten minutes—no parameter hunting, just a quick address set and bus check.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; not more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express shipping: FedEx, UPS, DHL

- All items are inspected and securely packed; we support traceable shipments and basic install guidance if needed.

Key Features

- PROFIBUS‑DP interface – Provides cyclic process data exchange with PLCs; ideal for synchronous speed/torque control over DP.

- Auto‑baud detection – Typically locks in from 9.6 kbit/s up to 12 Mbit/s, making mixed‑speed networks simpler to commission.

- 9‑pin Sub‑D (RS‑485) – Standard DP connector; supports shielded twisted pair per EN 50170 for noise‑resistant wiring.

- Backplane‑powered – No external supply; the host drive powers the option card, reducing wiring and potential failure points.

- Diagnostic LEDs – You might notice status at a glance (bus OK, errors, activity), which speeds up troubleshooting on the line.

- Compact, service‑friendly design – Installs into the drive’s option slot; typically no cabinet rework on replacements.

Technical Specifications

| Brand / Model | SEW‑EURODRIVE UFP11A‑00 |

| HS Code | 8538.90 (Parts for industrial control/switchgear) |

| Main Function | PROFIBUS‑DP fieldbus interface for SEW drives (legacy MOVIDRIVE A‑series) |

| Communication Interfaces | PROFIBUS‑DP (V0), RS‑485 physical layer, auto‑baud (approx. 9.6 kbit/s to 12 Mbit/s) |

| Signal I/O Types | 1 × PROFIBUS via 9‑pin Sub‑D; cyclic process data words and acyclic diagnostics (per DP profile) |

| Power Requirements | Supplied by host drive backplane (typ. 5 VDC; low power <2 W) |

| Installation Method | Plug‑in option card; secured in the drive’s option slot; front‑facing Sub‑D for field wiring |

| Dimensions & Weight | Compact plug‑in format; occupies one option slot; weight typically <0.2 kg |

| Operating Temperature | Approx. 0…+40 °C when installed in the drive; 5–95% RH non‑condensing |

| Compliance | EN 50170 wiring practices for PROFIBUS; intended for installation in IP54+ cabinets |

Related or Supporting Products

- SEW DFP21B – PROFIBUS‑DP option for newer MOVIDRIVE B series; higher diagnostics depth and updated firmware compared with UFP11A‑00.

- SEW DFD11B – DeviceNet option for MOVIDRIVE B; useful if your plant standard is DeviceNet instead of PROFIBUS.

- SEW DFE32B/DFE33B – PROFINET / EtherNet/IP options for Ethernet‑based PLC networks (newer drive families).

- PROFIBUS accessories – 9‑pin Sub‑D connectors with integrated termination, shielded DP cable (A‑type), repeaters for long segments.

- SEW engineering tools – GSD files and parameter tools (e.g., MOVITOOLS) for addressing and data mapping.

Installation & Maintenance

- Cabinet & environment – Install the host drive and option in a clean, ventilated control cabinet. Maintain clearance for airflow; avoid sources of high EMC noise near the DP cable.

- Wiring – Use shielded twisted‑pair PROFIBUS cable (A‑type). Terminate the bus at both ends only. Keep the drain wire bonded to the connector shell and cabinet ground to reduce noise.

- Addressing – Set the PROFIBUS node address per site standard (DIP switches or parameter, depending on drive generation). Load the correct SEW GSD in the PLC/engineering tool.

- Segment design – In most cases, limit to 32 devices per segment without repeaters; observe baud‑dependent maximum length. Use repeaters for longer runs or dense nodes.

- Safety – Power down the drive, wait for DC bus discharge, and observe ESD handling when inserting/removing the option card.

- Routine checks – Periodically verify connector tightness, shielding continuity, and inspect LED diagnostics. Firmware updates, when applicable, are performed on the host drive.

- Troubleshooting tip – If you see intermittent DP faults, re‑terminate the far end and check for mixed cable types or improper shield bonding. This resolves most sporadic bus errors we encounter.

Quality & Certifications

- Typically CE marked and UL/cUL recognized for installation in industrial control equipment.

- RoHS compliant hardware in most markets; documentation available on request.

- Manufacturer warranty usually 12 months; we back the item with a 365‑day warranty as part of our supply commitment.

Reviews

There are no reviews yet.