Description

Vibro-Meter VM600 AMC8 – Eight-channel analog monitoring card for machinery condition monitoring

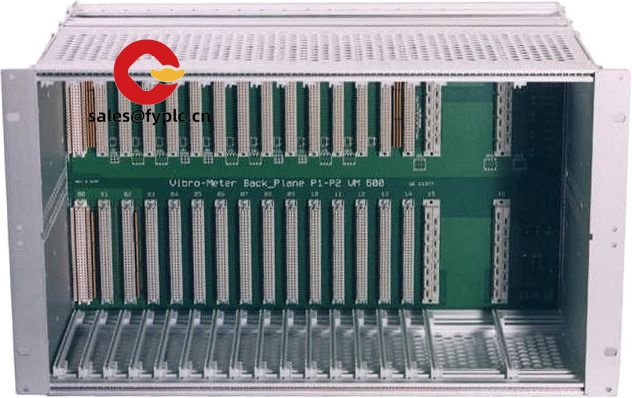

The Vibro-Meter VM600 AMC8 is an eight-channel analog monitoring module designed for the VM600 rack. From my experience, it’s a solid choice when you want reliable, rack-based acquisition of vibration and process signals without overcomplicating your cabinet. It plugs straight into the VM600 backplane, draws its power from the rack, and feeds high-quality condition monitoring data to your analysis environment, typically VibroSight via the rack controller.

Typical applications include steam and gas turbines, compressors, large fans, and critical pumps where you need stable, multi-channel data capture alongside machinery protection cards in the same frame. One thing I appreciate is how it slots into existing VM600 architectures—no awkward wiring changes—so projects move faster and maintenance teams aren’t dealing with one-off hardware.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Eight analog monitoring channels – Suited for vibration and process-type inputs, helping consolidate signals per machine train.

- VM600 rack integration – Powered via the backplane; configuration and data exchange are handled through the VM600 system controller.

- Condition monitoring data path – Works with the VM600 ecosystem and, in many cases, streams to VibroSight or a plant historian for trending and diagnostics.

- Buffered signal access – You might notice service engineers like the convenient buffered outputs for on-the-spot verification with portable analyzers.

- Hot-swappable module – Minimizes machine downtime; swap or add channels with the rack energized in most setups (follow site procedures).

- Industrial build – Designed for cabinet use around rotating equipment where stable, low-noise acquisition is key.

Technical Specifications

| Brand / Model | Vibro-Meter VM600 AMC8 |

| HS Code | 903180 (Measuring/monitoring instruments, other) |

| Power Requirements | Supplied via VM600 rack backplane; no external power supply required. |

| Channels / I/O Types | 8 analog monitoring channels; commonly used with dynamic vibration sensors (e.g., IEPE accelerometers/velocimeters) and AC/voltage-type inputs; buffered outputs typically available for field checks. |

| Communication Interfaces | Data and configuration via the VM600 rack controller over Ethernet (commonly integrated with VibroSight / Modbus TCP environments). |

| Operating Temperature | Typically 0 to +55 °C for VM600 modules (use the product datasheet and cabinet rating for final limits). |

| Installation Method | Hot-swappable plug-in card for the VM600 19-inch rack; front-panel access; termination via the matching VM600 I/O module. |

| Dimensions & Weight | Conforms to the standard VM600 module envelope; fits a single VM600 rack slot (consult the rack guide for exact size/weight). |

Related or Supporting Products

- VM600 XMV16 – High-density dynamic acquisition card (16 channels). If you’re short on rack space, this often reduces slot count compared to AMC8.

- VM600 MPC4 – Machinery protection card (4 channels). Use alongside AMC8 when you need API-compliant protection plus condition monitoring.

- VM600 IOC4T – I/O termination and relay interfacing. In many cabinets this handles field connections and discrete outputs.

- VM600 Rack Controller (CPUM/RCU) – Provides Ethernet connectivity and system configuration; typically used with VibroSight.

Installation & Maintenance

For best results, mount the VM600 rack in a ventilated 19-inch cabinet (front-to-rear airflow, maintain clearance around cable entries). Use shielded, low-noise cables for dynamic signals, and ground shields at the rack side to avoid ground loops. The AMC8 is hot-swappable, but follow your site’s LOTO and ESD procedures—especially when working around protection cards in the same frame.

- Power and earthing – Ensure clean rack supply and verified protective earth; noisy grounds are a common cause of drifting vibration trends.

- Sensor checks – Verify IEPE bias and cable integrity before commissioning; a quick buffered-out check typically saves hours later.

- Firmware/config – Keep the rack controller and monitoring software versions aligned; back up VM600 configurations after every change.

- Routine care – Annual channel verification against a handheld calibrator is usually enough; keep filters and cabinet dust under control.

“We added AMC8s to two compressor trains and kept our original protection cards. Trending is cleaner and our team likes the quick buffered checks,” a maintenance supervisor told me—pretty typical feedback when migrating to structured rack-based monitoring.

Quality & Certifications

- Certifications: CE-marked and RoHS conformity are standard for VM600 modules; UL/cUL recognition is available in many cases.

- Manufacturer quality: Built under ISO-managed processes typical for Vibro-Meter equipment.

- Warranty: 365-day warranty as supplied by us.

Reviews

There are no reviews yet.