Description

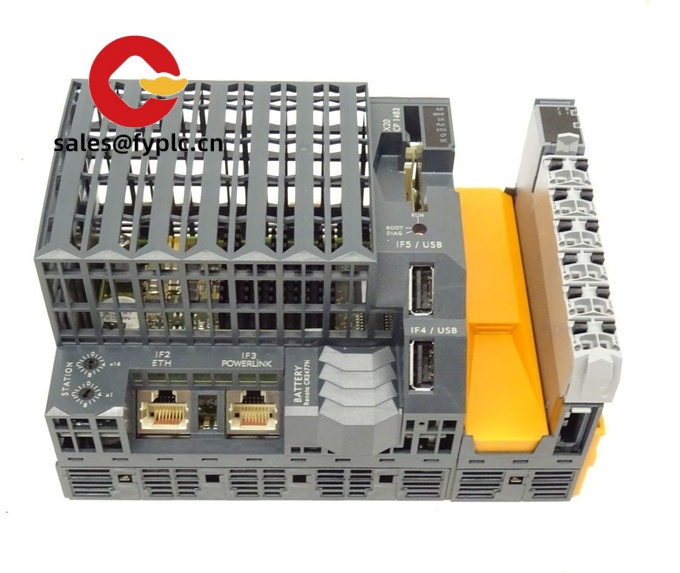

B&R X20CP1483 – Compact X20 CPU for Modular Machine Control

The B&R X20CP1483 is a compact controller from the X20 series designed for scalable, modular machine control. From my experience, it hits a sweet spot for mid-size packaging, assembly, and material handling lines where you want deterministic control, simple wiring, and easy expansion with slice I/O. You might notice that it keeps cabinet space tight while still giving you Ethernet-based programming and diagnostics, plus the flexibility to add fieldbus interfaces when needed.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in-stock units; no more than one month at the latest

- Payment: 50% advance payment; full balance prior to delivery

- Shipping: FedEx, UPS, or DHL

- Packing: Anti-static protection with shock-resistant secondary packing

- Traceable serials and photos of the actual unit before shipment (on request)

Key Features

- Modular X20 architecture – Add digital, analog, motion, and safety I/O slices directly on the backplane for tailored builds.

- Ethernet-based engineering – Program and diagnose via 10/100 Ethernet in B&R Automation Studio; remote maintenance is typically straightforward.

- Compact footprint – Slim slice form factor keeps control cabinets small, which in many cases lowers panel costs and simplifies retrofits.

- Service-friendly design – Removable terminals and clear status indicators help maintenance teams reduce downtime during swaps.

- Scalable communications – Fieldbus interfaces (e.g., CAN, POWERLINK, serial) can be added using X20 interface modules when the project grows.

- Deterministic control – Runs B&R Automation Runtime for cyclic real-time tasks common in packaging, printing, and intralogistics.

- Robust operating envelope – Industrial temperature range and vibration-resistant DIN-rail mounting suit 24/7 environments.

Technical Specifications

| Brand / Model | B&R X20CP1483 |

| HS Code | 8537.10 (Programmable control equipment, for a voltage not exceeding 1000 V) |

| Power Requirements | 24 VDC via X20 power supply module (X20PS series); consumption depends on configuration |

| Dimensions & Weight | X20 slice form factor; approx. 22.5 mm (W) x 99 mm (H) x 75 mm (D); ~0.15 kg |

| Operating Temperature | 0 to +55 °C (typical for X20 controllers) |

| Signal I/O Types | No onboard I/O; expandable with X20 digital/analog/safety/motion modules |

| Communication Interfaces | 1x Ethernet 10/100BASE‑TX (engineering/diagnostics); 1x USB service; X20 backplane; optional fieldbus via X20 interface modules |

| Installation Method | DIN-rail with X20 bus base (e.g., X20BB series) and terminal blocks |

| Programming Environment | B&R Automation Studio; Automation Runtime |

One thing I appreciate is how the X20CP1483 scales—teams often start with a single Ethernet port for engineering, then add CAN or POWERLINK with an interface slice as the machine evolves. A packaging OEM told us they swapped an older CP13xx for this unit and shaved around 10–15% off their cycle time after optimizing tasks in Automation Studio.

Related or Supporting Products

- X20CP1381 – Entry-level X20 CPU; suitable for smaller I/O counts and simpler cyclic tasks.

- X20CP1584 – Higher performance X20 CPU; typically more processing headroom and interfaces for motion-heavy lines.

- X20PS2100 – 24 VDC power supply module for X20 backplane power distribution.

- X20BB80 – Bus base for DIN-rail mounting and module interconnection.

- X20BM11 – Terminal block module; simplifies wiring and service replacement.

- X20IF10D1-1 – CAN interface module for connecting CAN-based devices and drives.

- X20IF1061-1 – Serial interface module for RS-232/RS-485 equipment (model-dependent specifics).

Installation & Maintenance

- Panel standards – Mount on grounded DIN rail inside a clean, dry, IP54+ cabinet. Maintain 0–55 °C ambient and non-condensing humidity.

- Ventilation – Allow space above/below modules for airflow; avoid heat sources. In most cases, 25–50 mm clearance reduces thermal stress.

- Wiring – Supply clean 24 VDC. Use shielded twisted pair for Ethernet/fieldbus when runs are long or noisy. Keep I/O and power separated where possible.

- Grounding – Bond the DIN rail and cabinet; ensure shields are terminated properly to minimize EMI.

- Firmware & backups – Keep Automation Runtime and project versions aligned. Export projects and back up parameters before updates.

- Routine care – Inspect connectors quarterly, remove dust with dry air, and verify diagnostic logs. Replace worn terminal blocks to prevent intermittent faults.

- Surge protection – Add transient protection on 24 VDC and network lines in high-noise or outdoor-adjacent installations.

Quality & Certifications

- Certifications: CE and RoHS compliant; cULus listing is common for the X20 platform (final compliance depends on hardware revision and options).

- Manufacturing: Produced under ISO 9001 quality systems.

- Warranty: 12 months standard coverage.

Reviews

There are no reviews yet.