Description

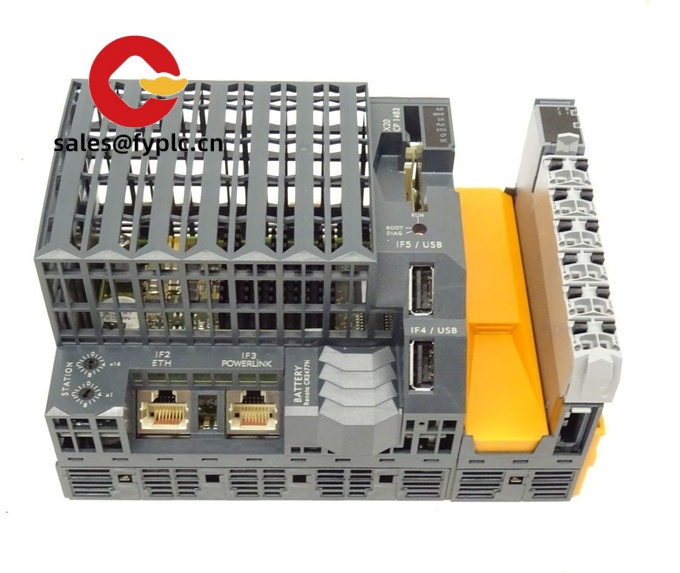

B&R X20BC8084 – Bus Controller for Ethernet POWERLINK Remote I/O

The B&R X20BC8084 is a compact bus controller for the X20 I/O system, typically used to bring distributed I/O nodes onto an Ethernet POWERLINK network. From my experience, it’s a reliable way to scale I/O close to machines and keep wiring simple—packaging lines, process skids, and robotic cells are common places you’ll see it. You might notice that it’s built for DIN-rail stations, so you snap on the terminal base, dock your X20 modules, and you’re ready to publish all those points upstream with deterministic timing.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Ethernet POWERLINK connectivity – Designed to expose an X20 I/O slice as a POWERLINK node with deterministic communication.

- X20 backplane compatibility – Supports the full mix of X20 digital, analog, motion, and specialty I/O modules via the internal X2X backplane.

- Compact DIN-rail form factor – Slim-width housing keeps control panels tidy; typically IP20 for cabinet installation.

- Service-friendly diagnostics – Status LEDs and a service/diagnostic port (commonly USB on this series) help during commissioning and troubleshooting.

- Industrial 24 VDC supply – Suits most machine panels; low power draw for efficient remote stations.

- Line-topology ready – In many cases this model includes dual RJ45 POWERLINK ports (integrated switch) for easy daisy-chaining on the machine.

Technical Specifications

| Brand / Model | B&R X20BC8084 |

| HS Code | 8537.10 (Programmable control apparatus) |

| Power Requirements | 24 VDC (typically 18–30 VDC), approx. 3 W consumption depending on I/O load |

| Dimensions & Weight | Approx. 99 × 22.5 × 85 mm; ~0.15 kg (typical for X20 bus controllers) |

| Operating Temperature | 0 to +55 °C (cabinet, IP20) |

| Signal I/O Types | Interfaces X20 backplane (X2X) for digital, analog, safety, and specialty I/O modules; no direct field I/O on the controller itself |

| Communication Interfaces | Ethernet POWERLINK (2 × RJ45, integrated switch in most cases); service/diagnostic port (commonly USB) |

| Backplane / Bus | X2X Link internal backplane for X20 I/O |

| Installation Method | DIN-rail mounting with X20 terminal base (e.g., X20TB12); front wiring, tool-less module latching |

| Protection Rating | IP20 (control cabinet use) |

Where it fits best

Typical use cases include adding a remote I/O island on a POWERLINK machine network, migrating legacy I/O to a modern deterministic bus, or breaking out high-density I/O near actuators to shorten cable runs. One thing I appreciate is how fast you can commission an X20 slice—engineers often tell us it’s a 20–30 minute job once the cabinet is ready.

Customer note: “We swapped in X20BC8084 on a filler line to split I/O across two conveyors. POWERLINK daisy-chain made the topology neat, and we didn’t touch the PLC—just mapped the new node.” (Maintenance Supervisor, beverage plant)

Related or Supporting Products

- X20BC8083 – Similar POWERLINK bus controller; typically differs in port configuration or diagnostics.

- X20BC0084 – Earlier/alternate variant with comparable function; check port features and firmware support.

- X20BC0085 – Economy/variant model used where simplified feature sets are acceptable.

- X20TB12 / X20TB0x – Terminal bases required for mounting X20 modules.

- X20BM11 – Bus module used to segment or extend X20 slices when designing larger stations.

- X20PS2xxx / X20PS9xxx – X20 power supply modules; choose based on total I/O load and redundancy needs.

- X20DI / X20DO / X20AI / X20AO series – Digital and analog I/O modules that dock directly behind the bus controller.

Installation & Maintenance

- Cabinet & mounting – Mount on a grounded DIN rail inside an IP20 control cabinet. Leave ventilation space (typically ≥50 mm above/below) and avoid heat sources.

- Power & wiring – Use 24 VDC SELV/PELV supplies. Keep I/O and communication cables separated; use shielded Cat5e/Cat6 for POWERLINK and bond shields at one end to reduce noise.

- Earthing & EMC – Bond the rail and panel ground well. Route motor cables away from the I/O slice to prevent coupled interference.

- Commissioning – Set the node parameters in Automation Studio, verify link/ACT LEDs, and map the X20 I/O channels. A quick power-cycle test usually confirms stable timing.

- Routine maintenance – Inspect connectors quarterly, clean dust with dry air, and keep firmware at the latest validated revision for your machine. Replace worn terminal bases if latch fatigue is noticed.

Quality & Certifications

- CE conformant; typically cULus Listed for the X20 platform

- RoHS compliant; produced under ISO 9001 quality systems

- Manufacturer’s standard warranty applies; we provide 365-day coverage on supply

If you’re replacing an existing POWERLINK node or standardizing remote I/O, the X20BC8084 hits a good balance of performance and footprint. If your application needs a specific port layout or extended temperature, let me know—we can verify the exact subvariant and firmware pairing before shipment.

Reviews

There are no reviews yet.