Description

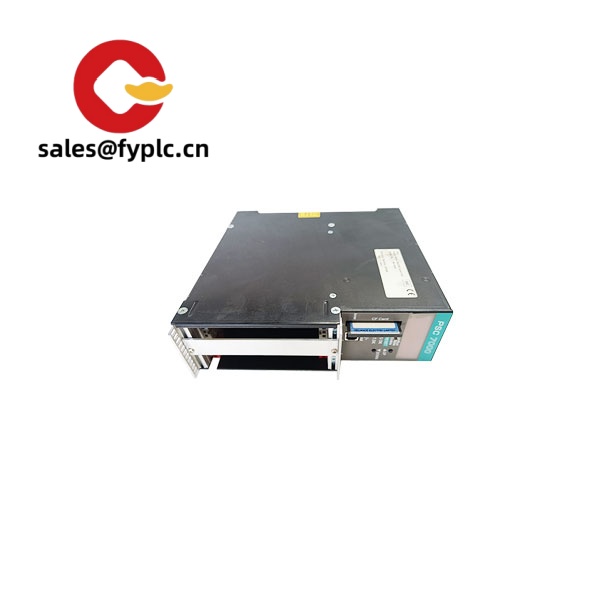

Reliance Electric WR-D4008 – Drive Control/Regulator Board for DC Drive Performance and Service Replacement

The Reliance Electric WR-D4008 is a plug-in control/regulator board used in Reliance Electric DC drive systems within the WR/WebPak/FlexPak families. From my experience, it’s the board many maintenance teams keep on the shelf for quick recovery when a drive trips and the control section is the suspect. It handles the analog command processing, loop regulation, and the interlocks that keep a DC motor running smoothly under varying loads. You might notice that it drops straight into the designated card slot and picks up power through the drive backplane—no messy external supply required.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Plug-in replacement – Drops into the WR-series control slot and uses the host drive’s backplane for power and I/O.

- Analog command handling – Typically supports ±10 V speed/torque references with onboard conditioning for stable regulation.

- Feedback compatibility – Works with the drive’s tach/armature feedback path; easy to tune for steady low-speed torque.

- Status and protection – Diagnostic test points and status indicators make fault tracing faster during downtime.

- Industrial build – Conformal-coated PCB and robust connectors suited for cabinet environments common in metals, paper, and converting lines.

- Service-friendly setup – DIP switches and trim pots (model dependent) simplify field adjustments without firmware tools.

Typical use cases include DC winder sections, extruders, paper machine sections, and mill stands where a stable speed loop and predictable torque response matter. One thing I appreciate is how quickly a trained tech can swap this card and restore a drive—often the fastest path to getting a line back up. A maintenance lead at a paper mill told us the WR-D4008 “bought us hours” because tuning was repeatable and the connectors line up exactly as expected.

Technical Specifications

| Brand / Model | Reliance Electric WR-D4008 (Drive control/regulator board) |

| HS Code | 853890 (Parts for electrical control apparatus) |

| Power Requirements | Supplied by host drive backplane; typically +5 VDC logic and ±15 VDC analog rails (no external supply) |

| Operating Temperature | 0 to +55°C typical when installed inside a ventilated control cabinet |

| Signal I/O Types | Analog reference ±10 V; speed/armature feedback via host drive; digital run/stop/fault lines through backplane I/O (model dependent) |

| Communication Interfaces | No native fieldbus on the board; integrates through Reliance Electric drive backplane |

| Installation Method | Plug-in card; secured in the designated WR-series slot with standoffs/screws and mating edge/connectors |

| Form Factor | Board-level module; compact PCB, nominal weight under 0.5 kg (varies by revision) |

Related or Supporting Products

- Reliance Electric WR-D4007 – Earlier/alternative control board used in similar DC drive frames; may require different jumper/DIP settings.

- Reliance Electric WR-D4010 – Later-series board with expanded adjustments on some drive models (compatibility depends on firmware revision).

- WebPak / FlexPak 3000 DC Drives – Common host platforms where the WR-D4008 is deployed for speed/torque regulation.

- Tachometer/Encoder feedback kits – Used to improve low-speed regulation; selection depends on motor speed and required resolution.

- Field/Armature I/O terminal kits – Replacement terminal blocks and harnesses that reduce downtime during board swaps.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated cabinet meeting industrial panel standards. Keep ambient within 0–55°C and protect from conductive dust.

- ESD and handling – Use a grounded wrist strap. Avoid touching analog sections and IC leads; seat connectors fully before power-up.

- Wiring and shielding – Route analog reference and feedback wiring away from armature and field cabling; use shielded pairs for analog signals.

- Grounding – Bond shields at a single point ground. Verify drive PE integrity to minimize noise in the speed loop.

- Setup and tuning – Confirm DIP switch positions and jumper links match the application. Adjust trim pots for reference gain, offset, and loop stability as specified in the drive manual.

- Routine checks – Every shutdown cycle, inspect for loose connectors, discoloration, or dust buildup. Lightly clean with dry air; avoid solvent sprays.

- Spare policy – Keep at least one tested spare on hand. In many cases, a pre-tuned card can cut restart time from hours to minutes.

Quality & Certifications

- Typically used within CE/UL/CSA listed drive systems; the board inherits compliance through the host drive.

- RoHS status varies by build vintage; supplied as an industrial spare part.

- Each unit is function-verified before dispatch; 365-day warranty applies.

- Certificate of Conformance available upon request.

If you’re replacing a failed control board or standardizing spares, share your drive model and firmware label. Compatibility on WR-series boards typically depends on those two details, and it seems to save a lot of back-and-forth to confirm that up front.

Reviews

There are no reviews yet.