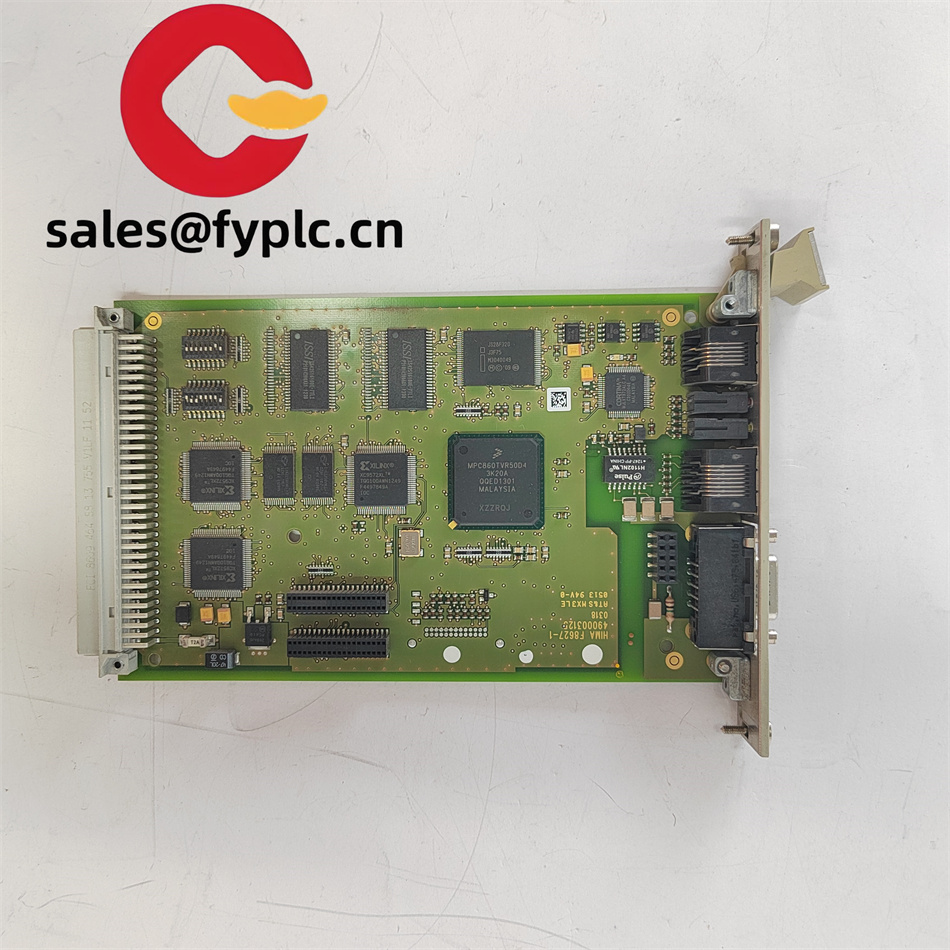

HIMA F8627X Communication Module Ethernet Communication Card

| Model Number | F8627X |

| Brand | HIMA |

| Type | Communication Module |

| Input Voltage | [Specify voltage range, e.g., 24 VDC ±15%] |

You are an experienced automation system engineer with expertise across global industrial hardware brands. Your task is to help craft rich, human-like, SEO-optimized English product content based on a specific product model I will provide. Focus on creating clear, original, and informative content that both technical buyers and search engines can easily understand.

Use the following semantic content blocks, but avoid sounding repetitive or overly structured. Prioritize flow, usefulness, and authenticity in every section.

- Introduction & Core Purpose

Begin with 2–3 natural paragraphs (approx. 300–400 words). Introduce the product naturally—describe what it is, what it’s built for, and what type of automation systems it supports. Be specific about its intended use (e.g., controller module, interface, communication handler). Emphasize how the product fits into broader industrial control systems.

- Include the full product name (Brand + Model)3–4 times using bold markdown

- Vary the sentence structure and phrasing to make it look hand-written

- Use industry-specific terms naturally, but avoid excessive jargon

- Ensure the first 50–100 words are keyword-dense and well-optimized for search engines

- Technical Highlights Table

Present the main technical parameters in a Markdown table format. Avoid lists or bullets. Use labels that are human-readable and consistent with how engineers search for specs online.

| Label | Specification |

| Model Number | [Model] |

| Brand | [Manufacturer] |

| Type | [Module Type] |

| Input Voltage | [Value] |

| Operating Temp | [Value] |

| Communication Method | [Value] |

| Mounting | [Value] |

| Weight | [Value] |

| Certifications | [Value] |

| Dimensions | [Value] |

| IP Rating | [Value] |

| Protocols Supported | [Value] |

(Include ~10-12 parameters, depending on the product)

- Functional Strengths & Design Advantages

In 2–4 well-structured paragraphs (300–400 words), explore what makes this product stand out in real-world industrial environments.

- Describe performance attributes (speed, resilience, interoperability)

- Highlight its build quality and compatibility with other systems

- Use natural phrasing—e.g., “This unit has been engineered to…” or “Operators benefit from…”

- No headings or bullets—write as free-flowing marketing copy

- Bold the product model name each time it appears

- Industrial Use Cases & Value Scenarios

Write 2 paragraphs (approx. 250–300 words) describing the environments where the product is typically deployed and what benefits it delivers.

- Reference specific industries or control setups (DCS, SCADA, etc.)

- Explain how the product solves specific operational challenges

- Use varied vocabulary to describe performance value

- Integrate keywords like: “industrial automation,” “control systems,” “process reliability,” “signal communication,” etc.

- Mention the model name at least twice in bold

- Compatible and Related Models

Create a short section naming 5–8 models closely related to the main product. For each model (bolded), add 1 short sentence explaining its relevance.

Example:

3BHE032025R0102 – A ruggedized alternative with enhanced thermal stability

3BHE029179R0101 – A compatible module from the same ABB family

Make sure each entry is short and helpful—do not write in a template tone.

- Setup & Service Guidance

Write around 200–250 words about how the product is typically installed and maintained over time.

- Mention any physical installation precautions (e.g., grounding, airflow, mounting)

- Offer insights into long-term operation: how often should it be inspected, what to look for

- Don’t use bullet points—write as continuous text

- Mention the model name in bold where relevant

- Avoid generic phrases like “easy to use”—instead focus on practical, real-world maintenance advice

- Warranty & Support Coverage

Finish with a paragraph (150–200 words) that reassures the buyer about product quality, warranty coverage, and technical support availability.

- Reaffirm manufacturer confidence in durability

- Include keyword-friendly phrases like “global support,” “long-term reliability,” “customer assurance”

- Mention availability of documentation or remote support

- Bold the product model name naturally

SEO & Content Guidelines:

- Language must appear naturally written—avoid AI-like sentence symmetry or pattern repetition

- Ensure product model appears in boldwherever mentioned (Markdown format)

- Do notuse bullet lists, numbered sections, or horizontal lines (HR)

- Maintain moderate paragraph lengthfor readability

- Avoid copying phrases or structures from datasheets or existing product pages

- Include technical keywords naturallyacross content (automation system, controller, module, etc.)

- Don’t overuse any single phrase—keep word diversity to avoid SEO penalties

- Focus on usefulness, clarity, and subtle marketing tone

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

HIMA F8627X Communication Module Ethernet Communication Card

HIMA F8627X: Elevating Industrial Safety and Communication

| Label | Specification |

|---|---|

| Model Number | F8627X |

| Brand | HIMA |

| Type | Communication Module |

| Input Voltage | [Specify voltage range, e.g., 24 VDC ±15%] |

| Operating Temp | -20°C to +60°C |

| Communication Method | Ethernet (RJ45), RS232/485, Profibus |

| Mounting | 19-inch rack-mountable (3 HU x 4 WU) |

| Weight | [Provide weight value] |

| Certifications | IEC 61508 (SIL 3), IEC 61511, ATEX, IECEx |

| Dimensions | 3 x 44.45mm (height) x 4 x 5.08mm (width) |

| IP Rating | IP20 (for indoor use) |

| Protocols Supported | Modbus/TCP, OPC UA, MQTT, Profibus DP |

Reviews

There are no reviews yet.