Description

FB201 SHIP BY DHL

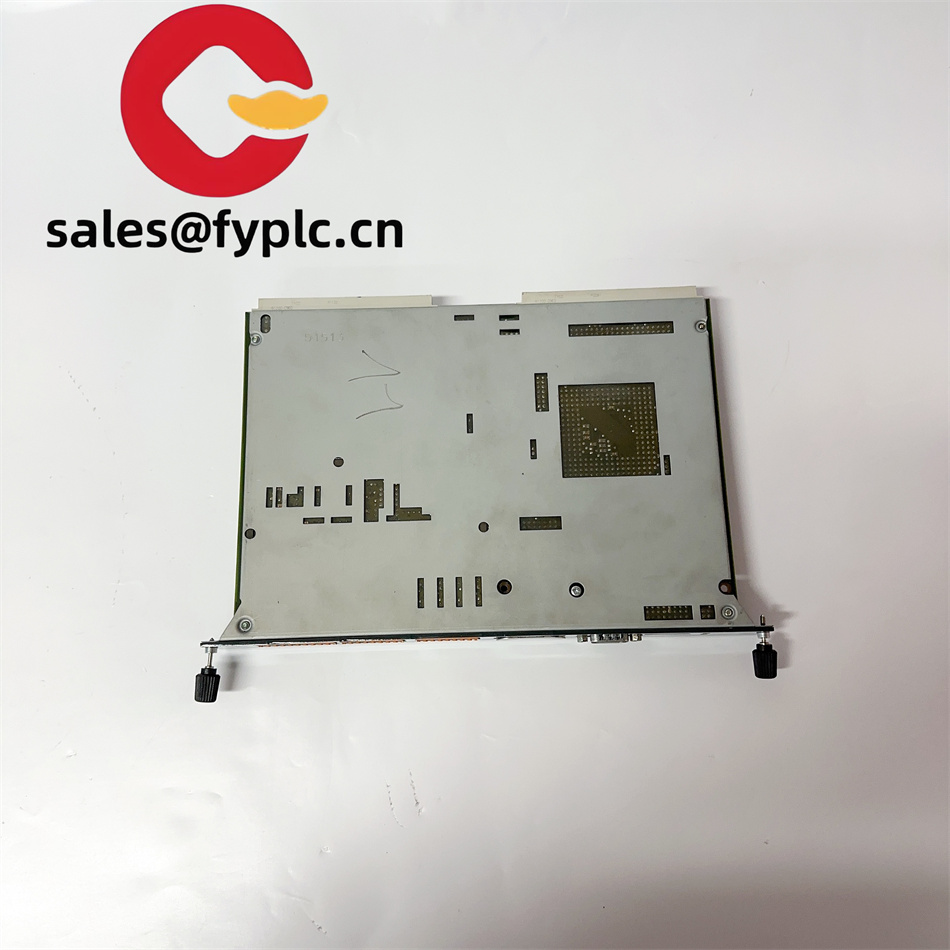

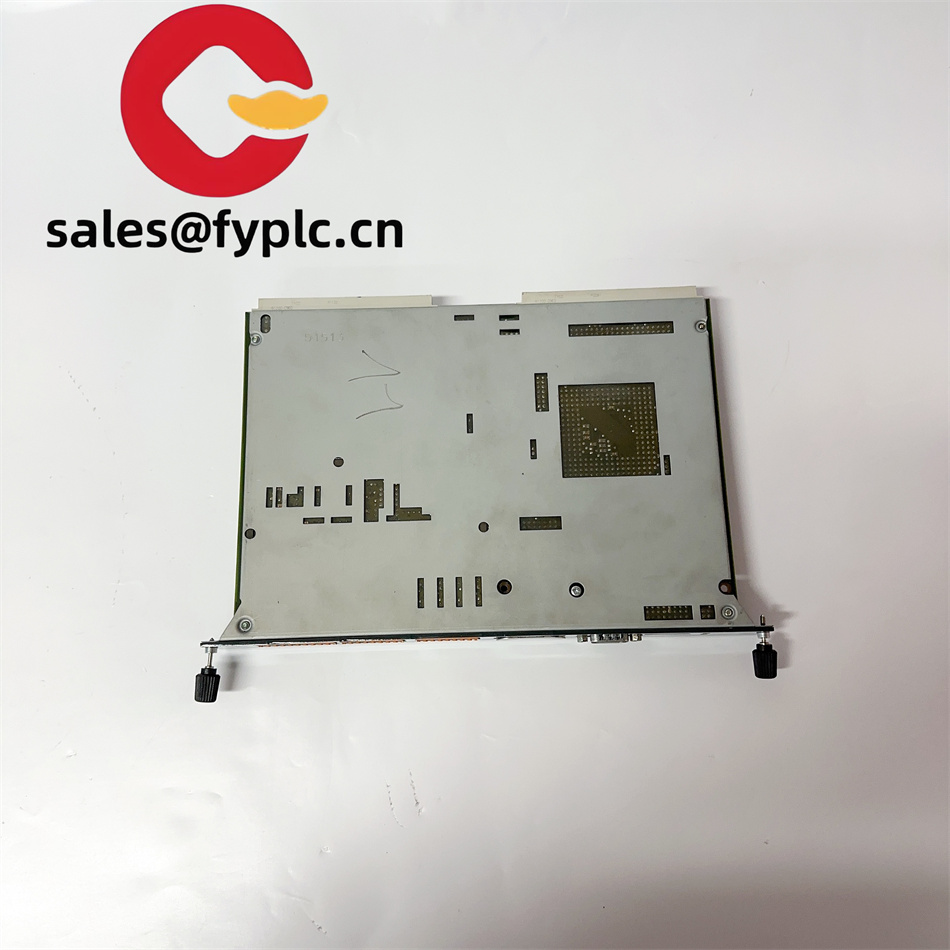

In the ever – evolving and demanding field of industrial automation, the FB201 Hyper – converged Server Hardware emerges as a revolutionary and reliable solution. Engineered to meet the complex and stringent requirements of modern industrial settings, this server hardware is a game – changer in the world of industrial control and data management.

The FB201 is designed to be the cornerstone of hyper – converged infrastructure in industrial applications. It seamlessly integrates computing, storage, and networking resources into a single, cohesive unit. This integration not only simplifies the deployment and management of industrial systems but also significantly enhances their efficiency and reliability. Whether it’s in a large – scale manufacturing plant, a power generation facility, or a chemical processing unit, the FB201 can be the backbone of the industrial automation setup, ensuring smooth operations and real – time data processing.

|

Label

|

Specification

|

|

Model Number

|

FB201

|

|

Type

|

Hyper – converged Server Hardware

|

|

Processor

|

[Specify the type and number of processors, e.g., Dual – socket Intel Xeon Scalable processors, offering high – performance computing capabilities with multiple cores and high clock speeds]

|

|

Memory

|

[Mention the memory capacity and type, e.g., Up to 2TB of DDR4 memory, with support for high – speed data access and error – correcting code (ECC) for data integrity]

|

|

Storage

|

[Describe the storage options, such as Support for a combination of high – capacity SAS/SATA HDDs for bulk data storage and fast – access NVMe SSDs for caching and critical data. For example, it could have up to 24 hot – swappable 2.5 – inch drive bays, allowing for flexible storage configuration]

|

The FB201 Hyper – converged Server Hardware offers several features that make it stand out in real – world industrial scenarios. Its high – performance processors enable rapid data processing, which is crucial for real – time analytics in industrial automation. For instance, it can quickly analyze sensor data from various industrial processes, such as temperature, pressure, and flow rate sensors, allowing for immediate decision – making. The large – capacity memory ensures that the server can handle multiple concurrent tasks without performance degradation. This is beneficial in industrial settings where there are often numerous virtual machines running simultaneously, each handling different aspects of the automation process.

The storage system of the FB201 is designed with a combination of fast – access SSDs and high – capacity HDDs. The SSDs are used as a cache, significantly improving the read and write speeds for frequently accessed data. The HDDs, on the other hand, provide cost – effective bulk storage for historical data and less – frequently accessed files. The hot – swappable drive bays allow for easy replacement of drives in case of failure, minimizing downtime. The redundant power supplies and cooling systems add to the server’s reliability, ensuring continuous operation even in the event of a power supply or cooling system failure.

In the manufacturing industry, the FB201 can be used to manage and control the production line. It can collect data from sensors on the production equipment, such as robots, conveyors, and quality control sensors. By analyzing this data in real – time, the server can optimize the production process, reducing waste and increasing productivity. For example, it can detect when a machine is about to malfunction based on sensor readings and schedule maintenance before a breakdown occurs. In power generation plants, the FB201 can monitor and control the power generation process. It can analyze data from generators, turbines, and other equipment to ensure stable power output and prevent power outages.

Related models in the hyper – converged server hardware space include the [Model A]. It is a lower – cost option, suitable for small – to – medium – sized industrial applications that have less demanding performance requirements. The [Model B] offers enhanced storage capacity, making it ideal for industries that need to store large amounts of historical data, such as the oil and gas industry. The [Model C] has advanced networking capabilities, with support for higher – speed network interfaces, which is beneficial for applications that require high – speed data transfer, like real – time video surveillance in industrial security systems. The [Model D] is designed for edge computing applications, with a more compact form factor and lower power consumption, suitable for deployment in remote industrial locations. The [Model E] comes with additional security features, such as built – in firewalls and intrusion detection systems, making it a great choice for industries where data security is of utmost importance, like the financial sector.

For more information, please click below to learn more:

Reviews

There are no reviews yet.