Description

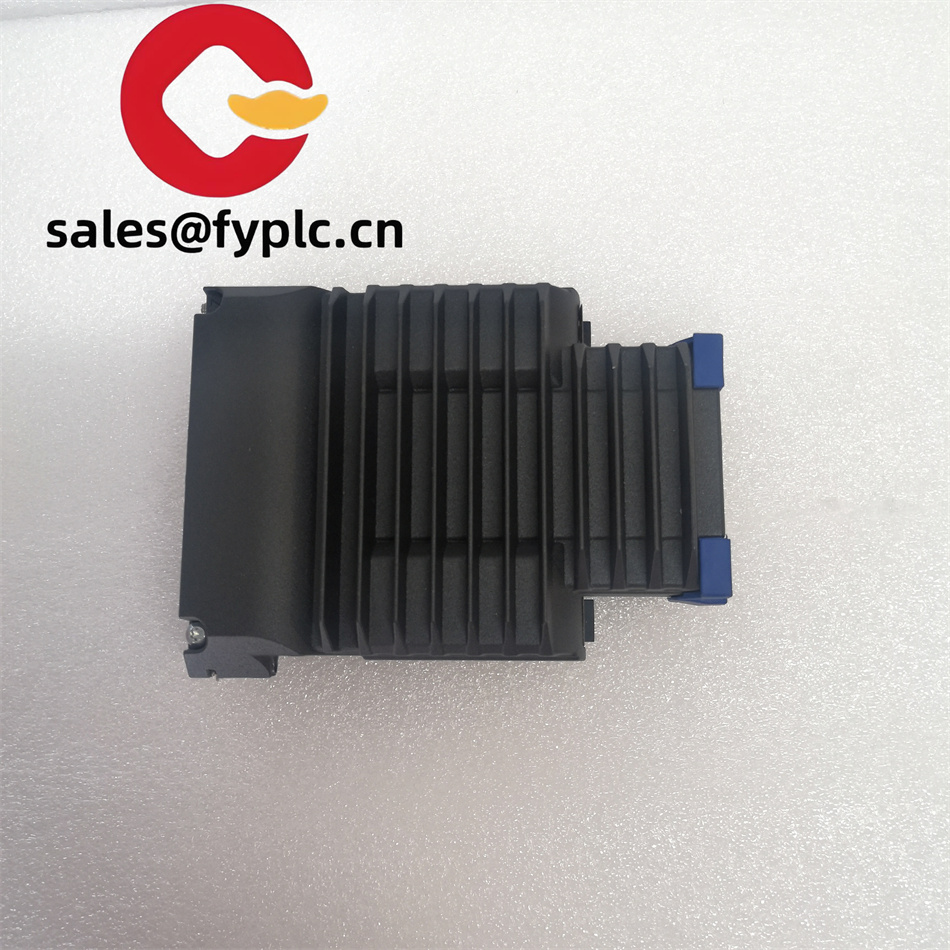

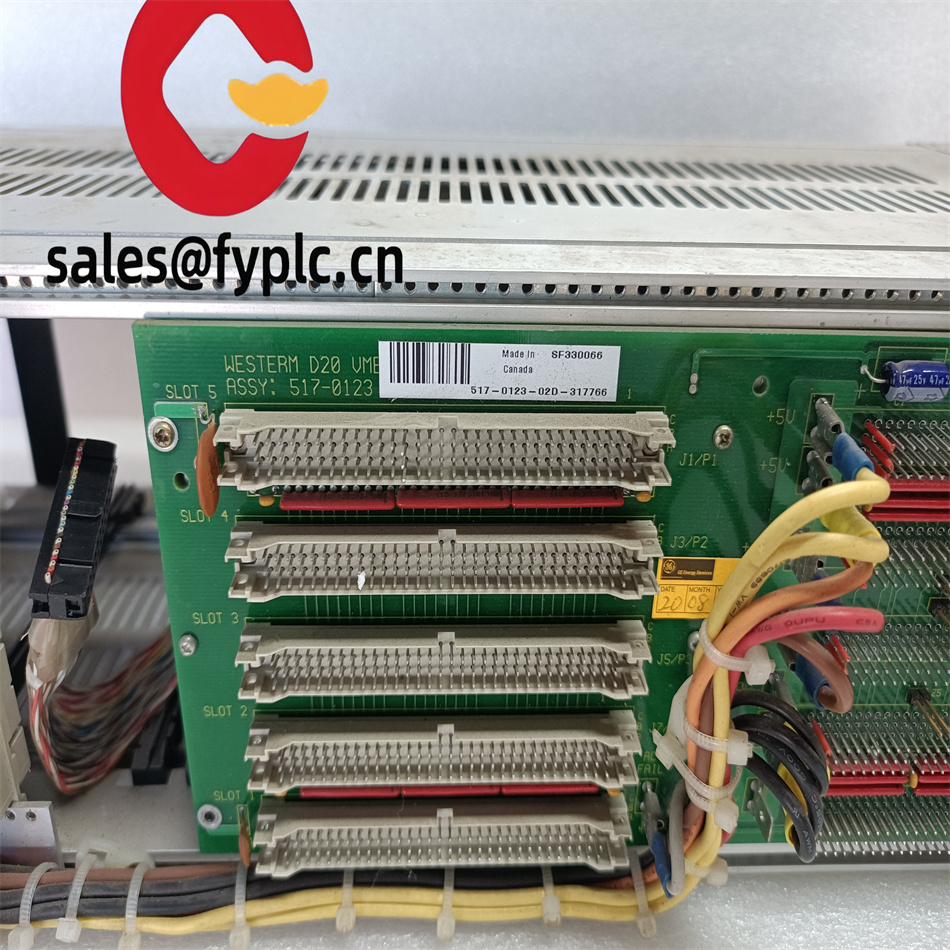

GE 04220FL11232A General Electric Field Input/Output Module

The GE 04220FL11232A is a ruggedized field interface module designed for mission-critical industrial automation systems, delivering seamless integration of sensors, actuators, and control devices. As part of GE’s RXi series, this module combines advanced I/O capabilities, multi-protocol communication, and industrial-grade reliability to address complex automation challenges in manufacturing, power generation, water treatment, and process industries. With support for protocols like Modbus RTU/TCP, Ethernet/IP, and Profibus DP, the 04220FL11232A acts as a central hub for real-time data exchange, making it ideal for retrofitting legacy systems or deploying next-generation smart factory solutions.

| Label | Specification |

|---|---|

| Model Number | 04220FL11232A |

| Brand | GE Intelligent Platforms |

| Type | Field Interface Module (RXi Series) |

| Input Voltage | 24–48VDC (±10%) |

| Operating Temp | -25°C to +65°C |

| Communication Methods | RS485, Ethernet/IP, Modbus RTU/TCP, Profibus DP |

| Mounting | DIN Rail (35mm) |

| Weight | 0.8 kg (Shipping Weight) |

| Certifications | CE, UL, ATEX Zone 2 |

| Dimensions | 125mm x 100mm x 75mm |

| IP Rating | IP54 (Dust and Water Splash Protection) |

| I/O Channels | 16 DI/16 DO + 8 AI/4 AO |

| Protocol Support | Modbus, Ethernet/IP, Profibus DP |

Reviews

There are no reviews yet.