Description

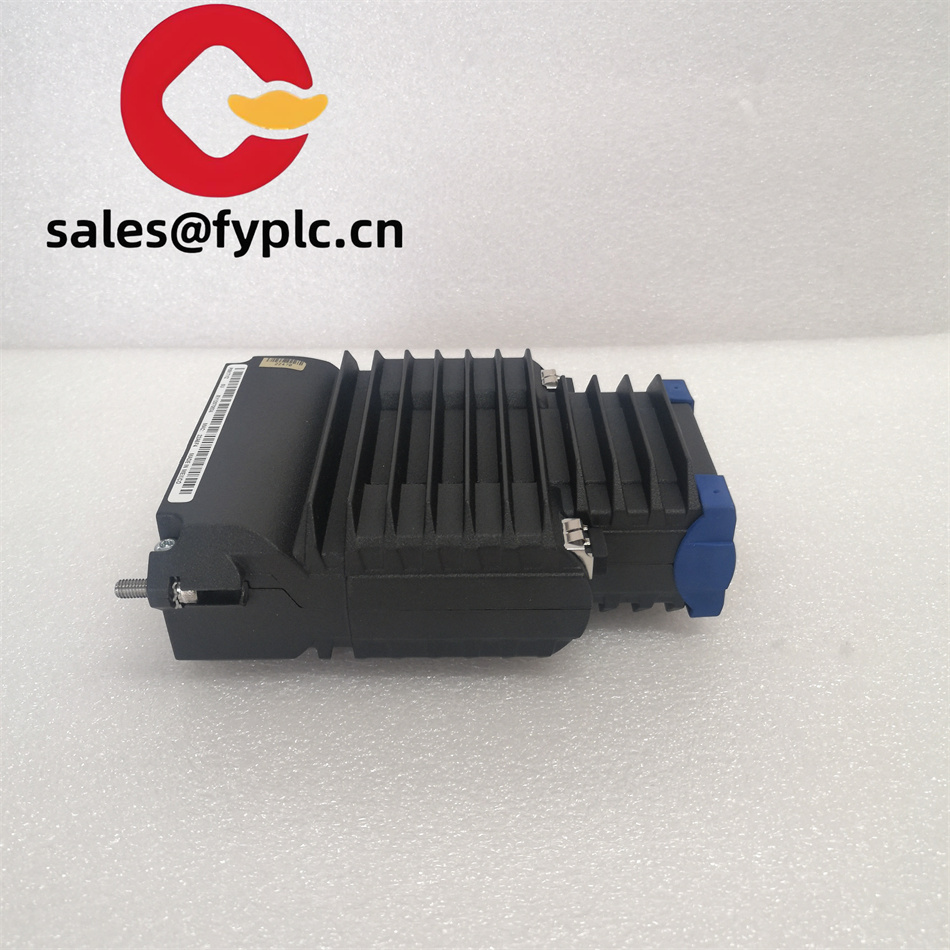

FOXBORO FCP270 P0917YZ High Performance Field Differential Pressure Controller

FOXBORO FCP270 P0917YZ: The Command Center of Industrial Automation

In the complex ecosystem of industrial automation, the FOXBORO FCP270 P0917YZ emerges as a central processing powerhouse, acting as the nerve center of industrial control systems. Developed by FOXBORO, a leading brand renowned for its cutting – edge industrial automation solutions, the FCP270 P0917YZ is meticulously engineered to handle the intricate demands of diverse industrial applications. It integrates advanced processing capabilities, reliable communication interfaces, and robust security features, making it an indispensable component for ensuring seamless operation, precise control, and enhanced productivity in industrial environments.

The FCP270 P0917YZ serves as the core controller within the Foxboro I/A Series distributed control system (DCS). Its primary role is to execute control strategies, process real – time data from various field devices, and manage communication between different components of the automation system. Whether it’s regulating complex chemical processes, optimizing power generation operations, or overseeing the production lines in manufacturing plants, this controller plays a pivotal part in translating control commands into actionable operations, thereby maintaining the stability and efficiency of industrial processes.

The FOXBORO FCP270 P0917YZ is packed with functional strengths and design advantages that set it apart in the industrial automation arena. Its high – performance microprocessor enables rapid data processing, allowing it to handle complex control algorithms and make split – second decisions. This is crucial in industrial settings where real – time monitoring and immediate responses to changing process conditions are essential. For instance, in a high – speed manufacturing line, the FCP270 P0917YZ can quickly analyze sensor data from multiple devices and adjust the production parameters in real – time to maintain product quality and production efficiency.

The controller’s support for hot – standby redundancy is a significant advantage. In the event of a hardware failure, such as a malfunctioning processor or a communication breakdown, the redundant unit can seamlessly take over operations without any interruption. This ensures continuous process control, minimizing downtime and preventing potential losses in industries where continuous production is critical, like the oil and gas sector or pharmaceutical manufacturing.

With its multiple communication interfaces, the FCP270 P0917YZ offers exceptional interoperability. The redundant 2 Mbps module fieldbus enables reliable communication with a wide range of I/O modules, such as the FBM242 RH916TA digital I/O module and FBM232 analog input/output module, facilitating the integration of diverse field devices. Additionally, the Ethernet connectivity allows for easy integration with higher – level control systems, enterprise networks, and remote monitoring platforms, enabling seamless data sharing and remote management.

The rugged design of the FCP270 P0917YZ is tailored to withstand the harsh conditions of industrial environments. Its wide operating temperature range ensures reliable performance in extreme cold or hot settings, while its compliance with strict electromagnetic compatibility standards allows it to operate without interference even in electrically noisy environments. Moreover, the built – in diagnostic features continuously monitor the health of the controller, providing early warnings of potential issues and enabling proactive maintenance to keep the system running smoothly.

Moreover, the built – in diagnostic features continuously monitor the health of the controller, providing early warnings of potential issues and enabling proactive maintenance to keep the system running smoothly.

For more information, please click below to learn more:

Moreover, the built – in diagnostic features continuously monitor the health of the controller, providing early warnings of potential issues and enabling proactive maintenance to keep the system running smoothly.

Moreover, the built – in diagnostic features continuously monitor the health of the controller, providing early warnings of potential issues and enabling proactive maintenance to keep the system running smoothly.

Reviews

There are no reviews yet.