GE UR6CH/UR6UH Data and Acquisition Communication Module

Tel: +86 17350880093

Whatsapp: 17350880093

E-mail : sales@fyplc.com

Zhangzhou Fengyun Electrical Equipment Co.LTD

Categories: GE

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

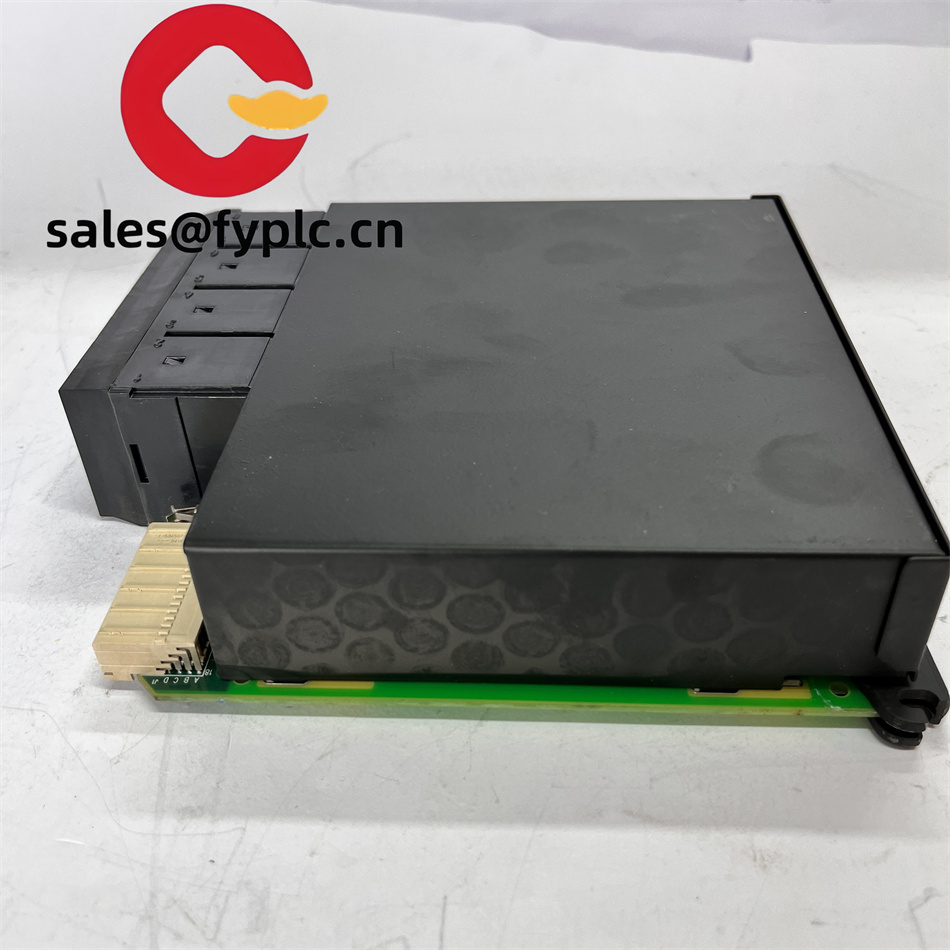

GE UR6CH Data and Acquisition Communication Module

In the vast landscape of industrial automation and control, precision and reliability are the key metrics for measuring equipment performance. The GE UR6CH from General Electric is a controller module that excels in meeting the stringent demands of industrial applications, playing a pivotal role in various complex industrial systems.

The GE UR6CH is meticulously crafted to tackle the challenges of industrial automation scenarios. Whether it’s the precise control of production processes in manufacturing or the stable monitoring of power generation and transmission in the energy sector, it proves to be highly effective. Within the industrial control architecture, it functions like the central nervous system, efficiently coordinating the operation of various devices and systems. It ensures smooth production processes and timely, accurate data transmission, providing a solid foundation for the stable operation of the entire industrial automation framework.

| Label | Specification |

|---|---|

| Model Number | UR6CH |

| Brand | General Electric |

| Type | Controller Module |

| Input Voltage | [Specific voltage range, e.g., 100 – 240V AC] |

| Operating Temp | [-20°C to 60°C] |

| Communication Protocols | Supports Modbus TCP, Ethernet/IP, etc. |

| Memory Capacity | [Specify the size, e.g., 2GB] |

| I/O Capability | [List the number of input and output points, e.g., 64 digital inputs, 32 digital outputs, etc.] |

| Mounting Style | DIN rail mounting or panel mounting |

| Weight | [X] kg |

| Dimensions | [Length X Width X Height in mm] |

| Certifications | Holds relevant certifications such as CE, UL |

The GE UR6CH delivers outstanding performance. Its processing speed is extremely rapid, enabling it to analyze and handle a large volume of complex data instantaneously and respond promptly to various control commands, significantly enhancing industrial production efficiency. For instance, on a high – speed automated production line, it can precisely adjust the operating parameters of equipment based on the data fed back by sensors in a timely manner, ensuring product quality consistency.

In terms of design, the GE UR6CH boasts excellent build quality. It features a rugged enclosure material that effectively withstands common interferences in industrial environments, such as dust, moisture, and mechanical vibrations. Moreover, this module offers remarkable compatibility. It can seamlessly interface with a wide range of industrial devices and systems from different brands and types. Whether it’s the latest intelligent sensors or traditional actuators, the GE UR6CH can work in harmony with them, facilitating the integration and upgrading of industrial systems with ease.

In real – world industrial applications, the value of the GE UR6CH is fully demonstrated. In the chemical production field, with its precise control capabilities, it can regulate critical parameters such as temperature, pressure, and flow rate inside reaction vessels in real – time. This ensures that chemical reactions occur in a safe and efficient environment, preventing production accidents caused by parameter fluctuations and strongly guaranteeing process reliability in chemical production.

In the construction of smart factories, the GE UR6CH also plays a central role. By closely collaborating with SCADA (Supervisory Control and Data Acquisition) systems, it can collect data from every aspect of the production line in real – time and feed this information back to the central control system. This provides managers with comprehensive and accurate production data, enabling them to make informed decisions, optimize production processes, and improve overall productivity.

There are numerous related models to the GE UR6CH, each with its unique features. The GE UR6CH – Plus enhances the basic model with additional data encryption functions, making it ideal for industrial scenarios involving sensitive data transmission, such as industrial automation processes related to financial data processing, where it can better safeguard data security. The GE UR6CH – Lite is a lightweight version. It is compact in size and relatively cost – effective, suitable for small – scale industrial automation projects with strict space requirements and budget constraints. The GE UR6CH – Pro is equipped with more advanced diagnostic features, which helps engineers quickly identify system faults and reduce equipment downtime, making it especially suitable for large – scale industrial production lines with high requirements for continuous operation. The GE UR6CH – XT focuses on improving adaptability to harsh environments, and it can operate stably in special industrial settings with high temperatures, high humidity, or even corrosive gases, finding great utility in industries like metallurgy and electroplating. The GE UR6CH – Wireless supports wireless communication, offering flexibility in the layout of industrial equipment and demonstrating its advantages in industrial sites where cable laying is difficult, such as the automated logistics systems in large warehouses.

When installing the GE UR6CH, strict adherence to relevant specifications is essential. For physical installation, if using the DIN rail mounting method, ensure that the rail is firmly installed and the GE UR6CH module is properly seated on the rail to avoid loosening. Loose mounting can lead to poor contact due to vibrations, affecting the module’s performance. In the case of panel mounting, make sure to leave sufficient space for heat dissipation to prevent the module from overheating due to poor ventilation, which could disrupt normal operation.

Regarding electrical connections, carefully follow the wiring diagrams provided in the product manual to ensure correct connections for power and signal cables. Additionally, proper grounding is crucial to effectively prevent electrical interference and static electricity from damaging the module.

During long – term operation, regular maintenance is indispensable. It is recommended to conduct a comprehensive inspection of the GE UR6CH every certain period (e.g., every three months). Check for dust accumulation on the module’s surface. If present, gently clean it with a clean, soft brush to avoid dust affecting heat dissipation and electrical performance. Also, inspect all connection cables for signs of damage or looseness, and promptly repair or replace any problematic cables. Furthermore, closely monitor the module’s status indicator lights. In case of abnormal flashing or 熄灭,immediately refer to the user manual or contact GE’s professional technical support for fault diagnosis and resolution.

For more information, please click below to learn more:

Be the first to review “GE UR6CH/UR6UH Data and Acquisition Communication Module” Cancel reply

Reviews

There are no reviews yet.