GE UR8LH configurable and expandable safety controller

Tel: +86 17350880093

Whatsapp: 17350880093

E-mail : sales@fyplc.com

Zhangzhou Fengyun Electrical Equipment Co.LTD

Categories: GE

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

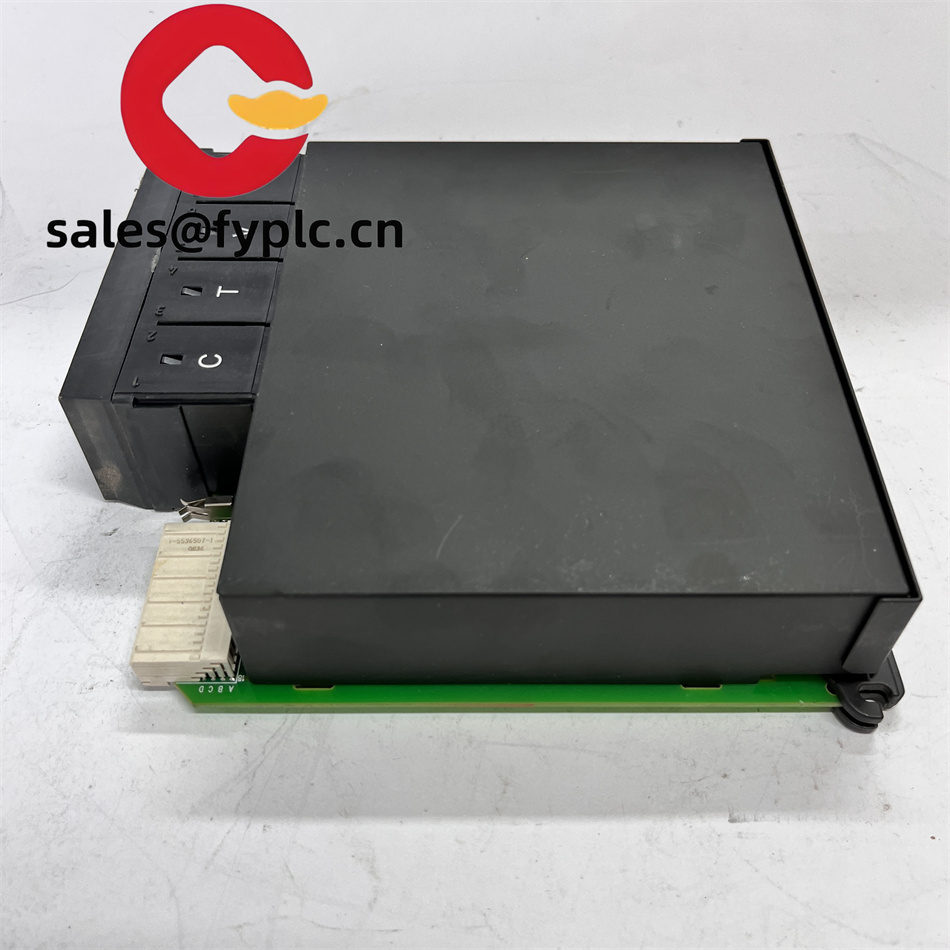

GE UR8LH configurable and expandable safety controller

In the intricate ecosystem of industrial automation, the GE UR8LH emerges as a highly capable and reliable analog input/output module, meticulously engineered by General Electric to address the diverse needs of modern industrial control systems. This module is a game – changer for industries that demand precise monitoring and control of analog signals, ensuring seamless integration and optimal performance within complex industrial setups.

The GE UR8LH is designed to thrive in a wide range of industrial environments, from large – scale manufacturing plants to sophisticated power generation facilities. Its primary purpose is to accurately measure and process analog signals from various sensors, such as temperature, pressure, and flow sensors, and convert them into digital data that can be easily understood and utilized by control systems. In power plants, it can monitor the temperature of critical components in turbines, ensuring they operate within safe parameters. In chemical processing plants, it helps regulate the flow of chemicals, maintaining the precision of the production process.

| Label | Specification |

|---|---|

| Model Number | UR8LH |

| Brand | General Electric |

| Type | Analog I/O Module |

| Input Voltage | [Specify input voltage range, e.g., 18 – 32V DC] |

| Operating Temp | -40°C to +70°C |

| Communication Protocols | [List supported protocols, e.g., Profibus DP, Modbus RTU] |

| Input Resolution | [Specify resolution, e.g., 16 – bit] |

| Output Resolution | [Specify resolution, e.g., 12 – bit] |

| Number of Channels | 8 analog inputs and 8 analog outputs |

| Mounting Style | DIN – rail mount |

| Weight | [Specify weight, e.g., 1.2 kg] |

| Dimensions | [Specify dimensions, e.g., 100mm x 80mm x 60mm] |

| Certifications | [List relevant certifications, e.g., CE, UL] |

The GE UR8LH boasts several outstanding functional strengths. Its high – resolution analog inputs ensure extremely accurate signal measurement, allowing for precise monitoring of process variables. This accuracy is crucial in industries where even the slightest deviation can lead to significant consequences. For example, in pharmaceutical manufacturing, precise temperature and pressure control are essential for product quality, and the GE UR8LH enables just that.

In terms of design, the module offers excellent build quality. Its rugged enclosure protects internal components from dust, moisture, and mechanical vibrations, ensuring reliable operation in harsh industrial conditions. The GE UR8LH also features exceptional interoperability, easily integrating with a wide variety of control systems and devices. This compatibility reduces the complexity of system integration and allows for greater flexibility in industrial automation projects.

In industrial use cases, the GE UR8LH proves its value time and again. In the oil and gas industry, it is used to monitor pipeline pressure and flow rates in real – time. By providing accurate and timely data, it helps operators detect leaks or blockages early, preventing potential disasters and minimizing downtime. In food and beverage production, it controls the filling levels of bottles and cans, ensuring consistent product quality and reducing waste.

There are several related models to the GE UR8LH. The GE UR8LH – Ultra offers enhanced precision and faster sampling rates, making it suitable for applications that demand the highest level of accuracy, such as high – end scientific research facilities. The GE UR8LH – Compact is a more space – efficient version, ideal for small – scale industrial setups where space is at a premium. The GE UR8LH – Pro comes with advanced diagnostic functions, enabling technicians to quickly identify and troubleshoot issues, reducing maintenance time and costs. The GE UR8LH – XP is designed for explosive – hazardous environments, meeting strict safety standards required in industries like petrochemicals. The GE UR8LH – Wireless incorporates wireless communication capabilities, providing greater flexibility in sensor placement and remote monitoring.

When it comes to the setup of the GE UR8LH, proper installation is essential for optimal performance. During installation, ensure that the DIN – rail is securely mounted and that the module is firmly attached to it. Pay close attention to electrical connections, following the wiring diagrams carefully to avoid any errors. Make sure to use appropriate shielding for analog signal cables to prevent interference.

For long – term maintenance, regular inspections are recommended. Check for any signs of physical damage to the module or its cables. Monitor the module’s operating temperature to ensure it stays within the specified range. Periodically calibrate the analog inputs and outputs to maintain accuracy. If any issues arise, the GE UR8LH‘s user – friendly design and detailed documentation make it relatively easy to diagnose and fix problems.

For more information, please click below to learn more:

Be the first to review “GE UR8LH configurable and expandable safety controller” Cancel reply

Reviews

There are no reviews yet.