Description

GE WESDAC D20ME High Performance Analog Input/Output Module

In the complex landscape of industrial control systems, the

GE WESDAC D20ME emerges as a powerful and reliable solution. This substation automation controller module is meticulously crafted by GE to revolutionize operations in a variety of industrial settings. Whether it’s ensuring seamless power distribution in substations, enabling precise control in industrial processes, or facilitating real – time monitoring in complex automation setups, the

GE WESDAC D20ME is up to the task. It serves as a linchpin in industrial automation, integrating smoothly with other components to drive efficiency and reliability across the board.

The GE WESDAC D20ME is not just an ordinary module; it’s a technological marvel designed to meet the challenges of modern industrial environments. Its advanced capabilities make it suitable for a wide range of applications, from large – scale manufacturing plants to critical power generation facilities. By providing accurate control and real – time data processing, it empowers industries to optimize their operations and stay ahead in a competitive market.

|

Label

|

Specification

|

|

Model Number

|

WESDAC D20ME

|

|

Brand

|

GE

|

|

Type

|

Substation Automation Controller Module

|

|

Input Voltage

|

110 – 240 V AC20 – 60 V DC, 100 – 300 V DC (varies by source)

|

|

Operating Temp

|

– 40°C to 85°C

|

|

Communication Method

|

Ethernet, Serial (RS – 232/485), D.20 Link HDLCSupports protocols like IEC 61850, DNP 3, Modbus

|

|

Mounting

|

Standard rack mount (details may vary)

|

|

Weight

|

Approximately 4.5 kg (10 lbs) – 6 kg (varies by source)

|

|

Certifications

|

CE, UL, ISO 9001 (varies by source)

|

|

Dimensions

|

19″ x 12″ x 3.5″ (482.6 mm x 304.8 mm x 88.9 mm)Or other dimensions as per different sources

|

|

IP Rating

|

IP65

|

|

Protocols Supported

|

IEC 61850, DNP 3, Modbus, etc.

|

One of the standout features of the GE WESDAC D20ME is its remarkable processing speed. Equipped with an advanced microprocessor, it can swiftly handle complex control algorithms, ensuring minimal latency in control loops. This means faster response times to changes in industrial processes, leading to more stable and efficient operations. Its resilience is equally impressive. Built with rugged materials, it can endure harsh environmental conditions, including extreme temperatures, electrical interference, and mechanical vibrations. This makes it a perfect fit for industrial environments where reliability is non – negotiable.

Interoperability is another feather in the cap of the GE WESDAC D20ME. It supports a wide range of communication protocols, allowing it to integrate seamlessly with various existing systems and devices. Whether it’s connecting to sensors, actuators, or other control modules, the module ensures smooth data flow and effective communication. The high – quality build of the GE WESDAC D20ME guarantees long – term durability. With proper maintenance, it can operate reliably for years, reducing the need for frequent replacements and minimizing costly downtime. Operators also benefit from its user – friendly programming interface, which simplifies configuration and maintenance tasks, enabling them to focus on optimizing system performance.

The GE WESDAC D20ME finds extensive use in numerous industrial scenarios. In power distribution substations, it plays a crucial role in monitoring and controlling the flow of electricity. By precisely regulating voltage levels, controlling circuit breakers, and monitoring equipment health, it ensures the stable and safe distribution of power. In renewable energy substations, such as wind or solar farms, the module helps manage the integration of energy generation from these sources into the grid. It monitors the performance of generators, controls power inverters, and facilitates communication between different components of the renewable energy system.

In industrial plants, the

GE WESDAC D20ME is used to automate manufacturing processes. It coordinates the operation of various machines, such as conveyor belts, robotic arms, and processing equipment, to ensure smooth production flow. By accurately controlling these machines, it helps maintain product quality, increase production efficiency, and reduce waste. In smart grid applications, the module enables real – time communication between different grid components, allowing for better management of power distribution, improved fault detection, and enhanced grid resilience.

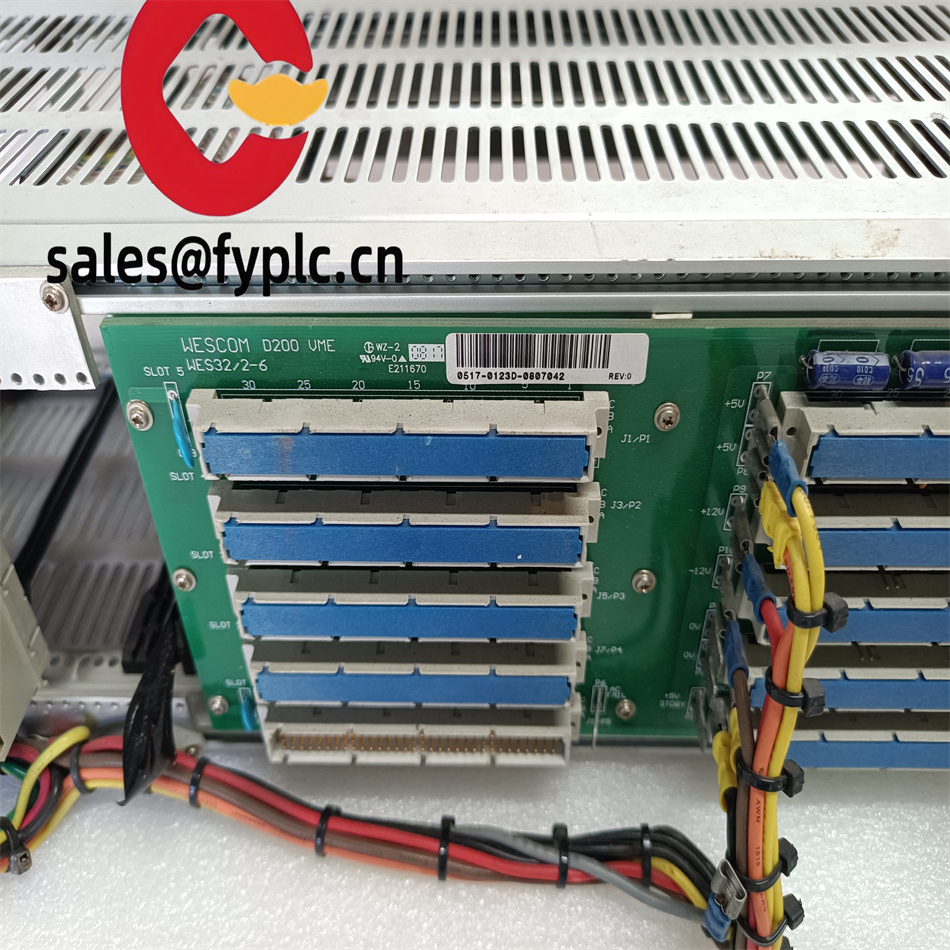

When considering related models in the GE portfolio, the GE WESDAC D20ME II is an upgraded version that offers enhanced processing power and additional features, making it suitable for more complex substation automation tasks. The GE WESCOM D200 VME is a different – type module that, while having a different form – factor and application focus, can complement the GE WESDAC D20ME in large – scale industrial control systems where multiple types of modules are required for comprehensive control. The GE WESDAC D10ME might be a more compact and cost – effective option for smaller – scale substation or industrial applications where space is limited and the control requirements are relatively less complex. The GE WESDAC D30ME could offer higher – end performance, perhaps with more advanced communication capabilities or increased processing speed, for applications that demand top – tier control and monitoring. The GE WESDAC D25ME may provide a balance between the features of the D20ME and D30ME, with some additional functionality or improved performance in specific areas like power handling or network connectivity.

Installing the

GE WESDAC D20ME requires careful attention to detail. When mounting it in a rack, ensure that it is properly aligned and securely fastened to prevent any movement that could disrupt connections. Adequate grounding is essential to protect the module from electrical surges and ensure stable operation. Also, consider the airflow around the module; proper ventilation is crucial to maintain optimal operating temperatures, as overheating can lead to performance degradation and component failure. Make sure to follow the installation instructions provided by GE carefully to ensure a successful setup.

For long – term operation, regular inspections are highly recommended. Check for any signs of physical damage, such as cracks or dents on the module’s casing. Inspect the connections to ensure they are tight and free from corrosion. Monitor the module for any abnormal heat generation, as this could indicate a problem with the internal components. Periodically update the module’s firmware to benefit from the latest features, performance improvements, and security enhancements. By following these maintenance practices, you can ensure that the GE WESDAC D20ME continues to perform reliably over its lifespan.

GE stands firmly behind the GE WESDAC D20ME with a comprehensive warranty and excellent support coverage. The manufacturer’s confidence in the product’s durability is evident in the generous warranty period offered, which provides peace of mind to buyers. In addition to the warranty, customers have access to a global network of technical support experts. These experts are well – versed in the GE WESDAC D20ME and can assist with any queries, from installation – related issues to troubleshooting complex problems. Extensive documentation, including user manuals, installation guides, and troubleshooting handbooks, is available to help users get the most out of the module. With remote support options, GE ensures that assistance is just a click or a call away, further enhancing customer assurance and the long – term reliability of the GE WESDAC D20ME.

For more information, please click below to learn more:

In the complex landscape of industrial control systems, the GE WESDAC D20ME emerges as a powerful and reliable solution. This substation automation controller module is meticulously crafted by GE to revolutionize operations in a variety of industrial settings. Whether it’s ensuring seamless power distribution in substations, enabling precise control in industrial processes, or facilitating real – time monitoring in complex automation setups, the GE WESDAC D20ME is up to the task. It serves as a linchpin in industrial automation, integrating smoothly with other components to drive efficiency and reliability across the board.

In the complex landscape of industrial control systems, the GE WESDAC D20ME emerges as a powerful and reliable solution. This substation automation controller module is meticulously crafted by GE to revolutionize operations in a variety of industrial settings. Whether it’s ensuring seamless power distribution in substations, enabling precise control in industrial processes, or facilitating real – time monitoring in complex automation setups, the GE WESDAC D20ME is up to the task. It serves as a linchpin in industrial automation, integrating smoothly with other components to drive efficiency and reliability across the board.

Reviews

There are no reviews yet.