Description

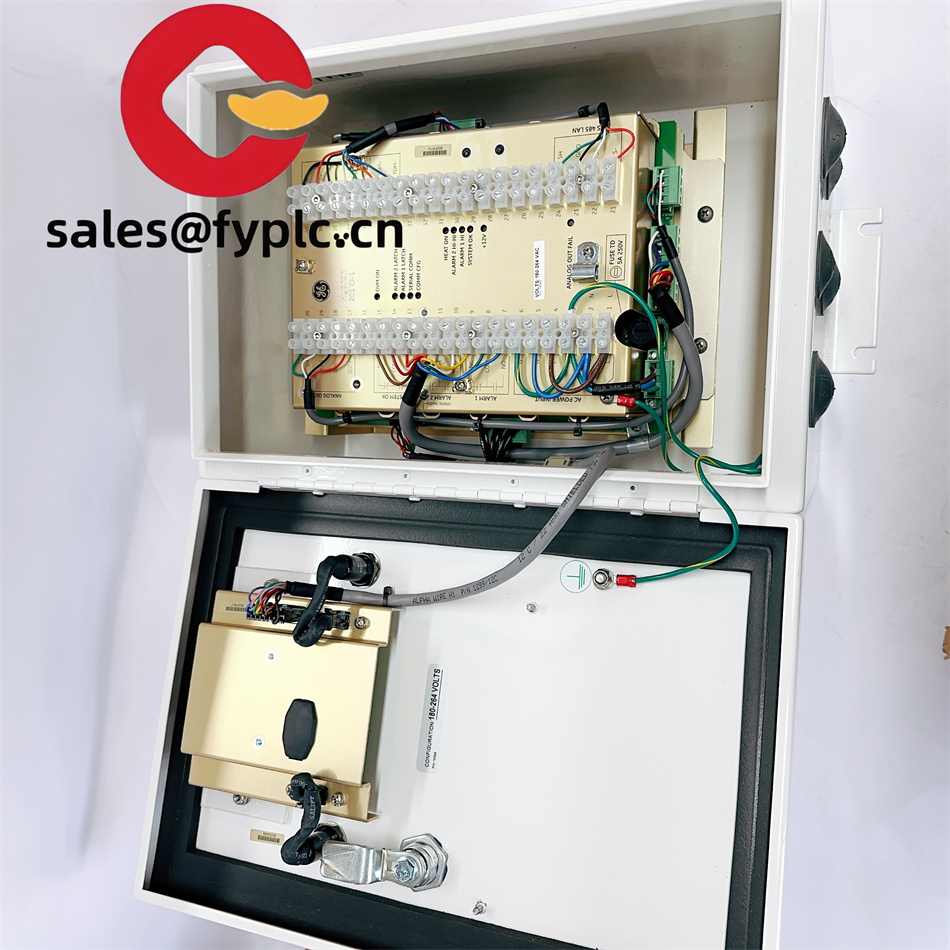

GE H201Ci-1 Gas Detection Single Channel Controller Thermocouple Terminal Board

|

Label

|

Specification

|

|

Model Number

|

H201Ci – 1

|

|

Brand

|

GE

|

|

Type

|

One – Channel Controller

|

|

Input Voltage

|

90 – 132V AC / 180 – 264V AC

|

|

Operating Temp

|

-40°C to 70°C (-40°F to 158°F)

|

|

Communication Method

|

Supervisory link for connection with Hydran 201ti transmitter

|

|

Mounting

|

Installed on anti – vibration mounts

|

|

Weight

|

23.25 lbs

|

|

Certifications

|

Complies with relevant industrial safety and performance standards

|

|

Dimensions

|

23.00 x 13.00 x 11.50 inches

|

|

Output

|

Isolated analog 4 – 20 mA outputs over 0 – 2000 ppm range

|

|

Alarm Capabilities

|

High and high – high alarms for gas level, fail alarms for power failures and system malfunctions

|

The GE H201Ci – 1 stands out in real – world industrial environments due to its remarkable functional strengths and design advantages. It processes gas – related data with high precision, allowing for accurate measurement of gas concentrations within the 0 – 2000 ppm range. This precision is crucial for industries where even the slightest deviation in gas levels can lead to safety hazards or operational inefficiencies.

The GE H201Ci – 1 stands out in real – world industrial environments due to its remarkable functional strengths and design advantages. It processes gas – related data with high precision, allowing for accurate measurement of gas concentrations within the 0 – 2000 ppm range. This precision is crucial for industries where even the slightest deviation in gas levels can lead to safety hazards or operational inefficiencies.

Reviews

There are no reviews yet.